Automatic control device of mine auxiliary shaft elevator

An automatic control device and hoist technology, applied in elevators, transportation and packaging, elevators in buildings, etc., can solve the problems of easy malfunction, low reliability, and inability to achieve centralized control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

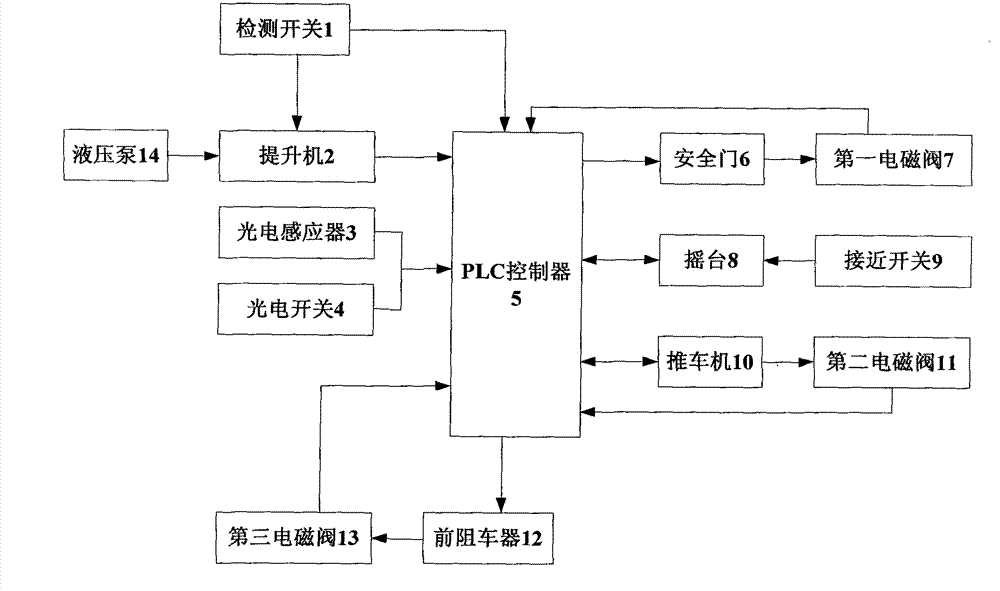

[0017] Such as figure 1 As shown, an automatic control device for a hoist in a mine auxiliary shaft includes a hoist 2 and a trolley machine 10, and the hoist 2 includes a safety door 6, a cradle 8 and a front car stopper 12 arranged in a cage. The outer side of the hoist 2 is provided with a detection switch 1 for detecting that the cage is in place, and the detection switch 1 transmits the signal that the cage is detected to be in place to the hoist 2 and the PLC controller 5 respectively, and the hoist 2 and the PLC controller 5 Electrically connected; the output end of the PLC controller 5 is connected with the input end of the safety door 6 and the front car stopper 12 respectively, and the PLC controller 5 is also interactively connected with the cradle 8 and the cart machine 10 respectively; The front end of the car device 12 is provided with a photoelectric sensor 3, and the exit side of the safety door 6 is provided with a photoelectric switch 4, and the output termin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com