Method for preparing superfine cuprous oxide powder

A technology of cuprous oxide powder and organic copper, which is applied in the direction of copper oxide/copper hydroxide, etc., can solve the problems of high equipment sealing requirements, high power consumption, harsh reaction conditions, etc., and achieve good secondary dispersion and energy consumption The effect of low cost and low preparation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Add 12g of copper sulfate pentahydrate and 30g of sodium hypophosphite into 2L of dimethyl sulfoxide solution, and heat the solution to 50°C; adjust the pH of the solution to 1.5 with sulfuric acid, and react for 2 hours; centrifuge the obtained turbid solution, Wash and dry to obtain cuprous oxide powder.

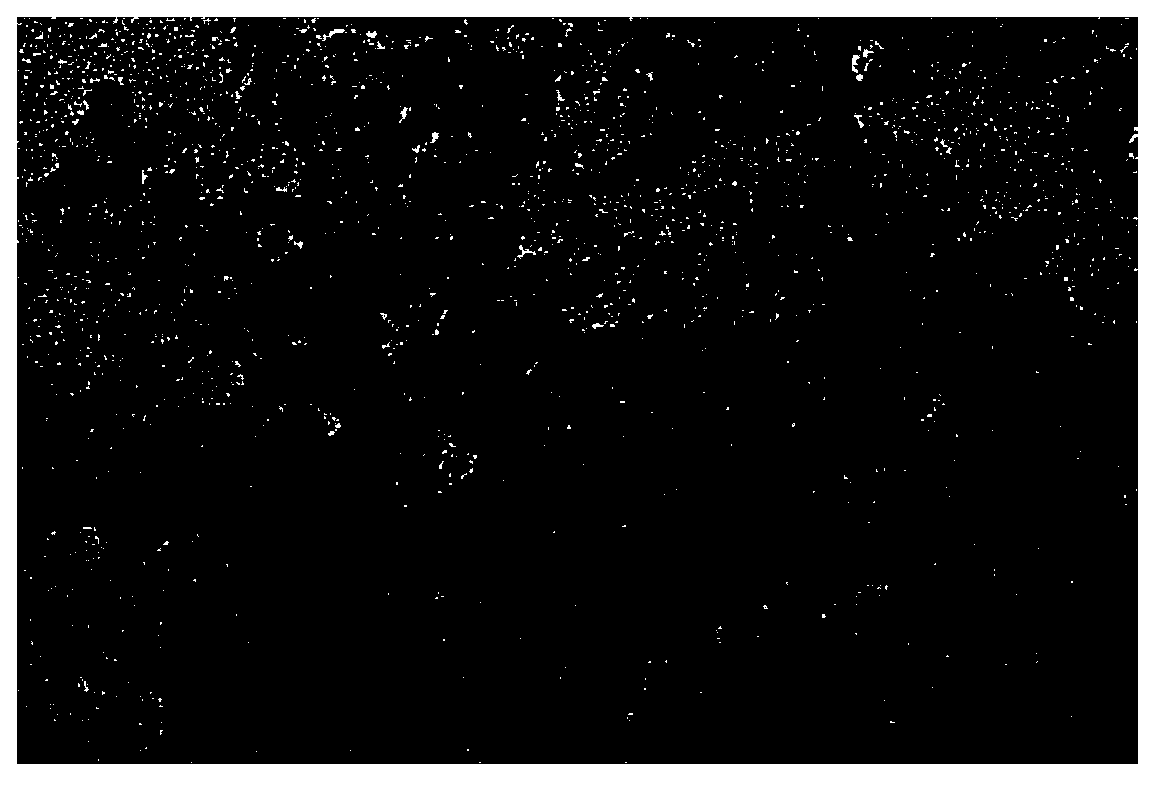

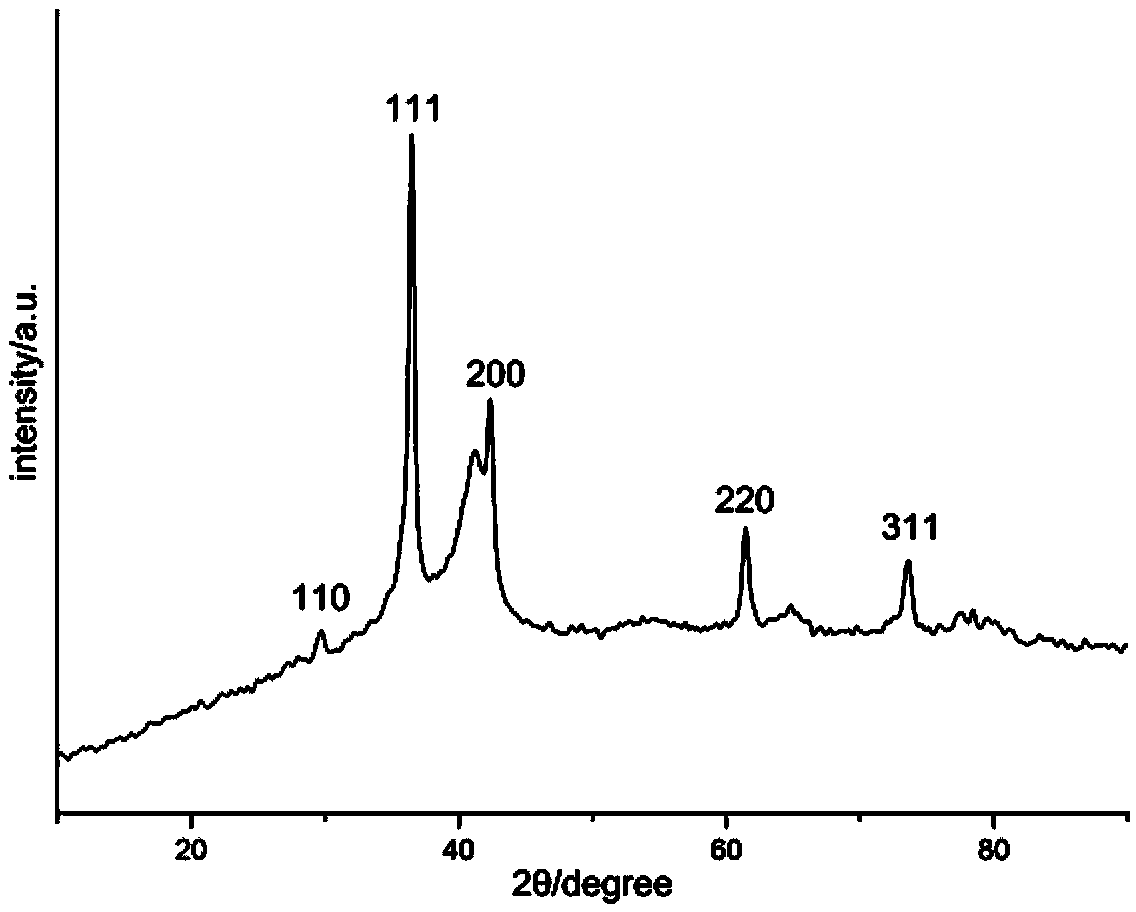

[0025] Gained cuprous oxide powder is observed by transmission electron microscope (TEM), as figure 1 As shown, it can be seen that its particle size is less than 20nm, and the X-ray test pattern is as follows figure 2 shown.

Embodiment 2

[0027] Add 126g of copper acetate and 120g of sodium borohydride into 10L of dimethyl sulfoxide solution, heat the solution to 30°C, and react for 1h; centrifuge, wash and dry the resulting turbid solution to obtain cuprous oxide powder with a particle size of less than 20nm .

Embodiment 3

[0029] Take 12g of copper nitrate and 25g of sodium sulfite (heptahydrate) and add them to 1L of dimethyl sulfoxide solution, and heat the solution to 40°C, and use sulfuric acid to maintain the pH of the solution=2.5, and react for 1h; centrifuge, wash, and Dry to obtain cuprous oxide powder with particle size less than 20nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com