Electroplating workpiece conveying mechanism

A technology for conveying mechanisms and workpieces, applied in electrolytic components, electrolytic processes, etc., to improve efficiency and solve electroplating problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

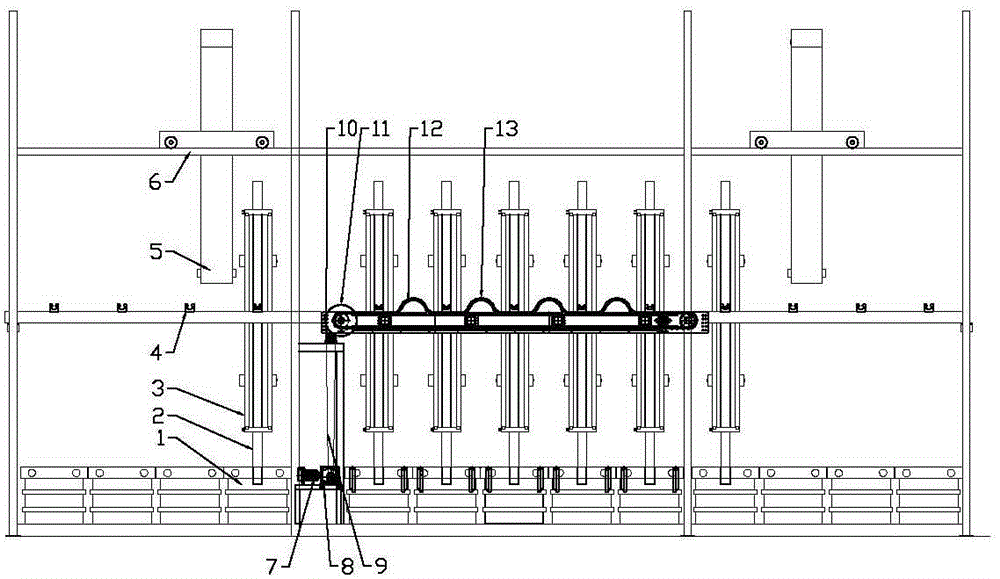

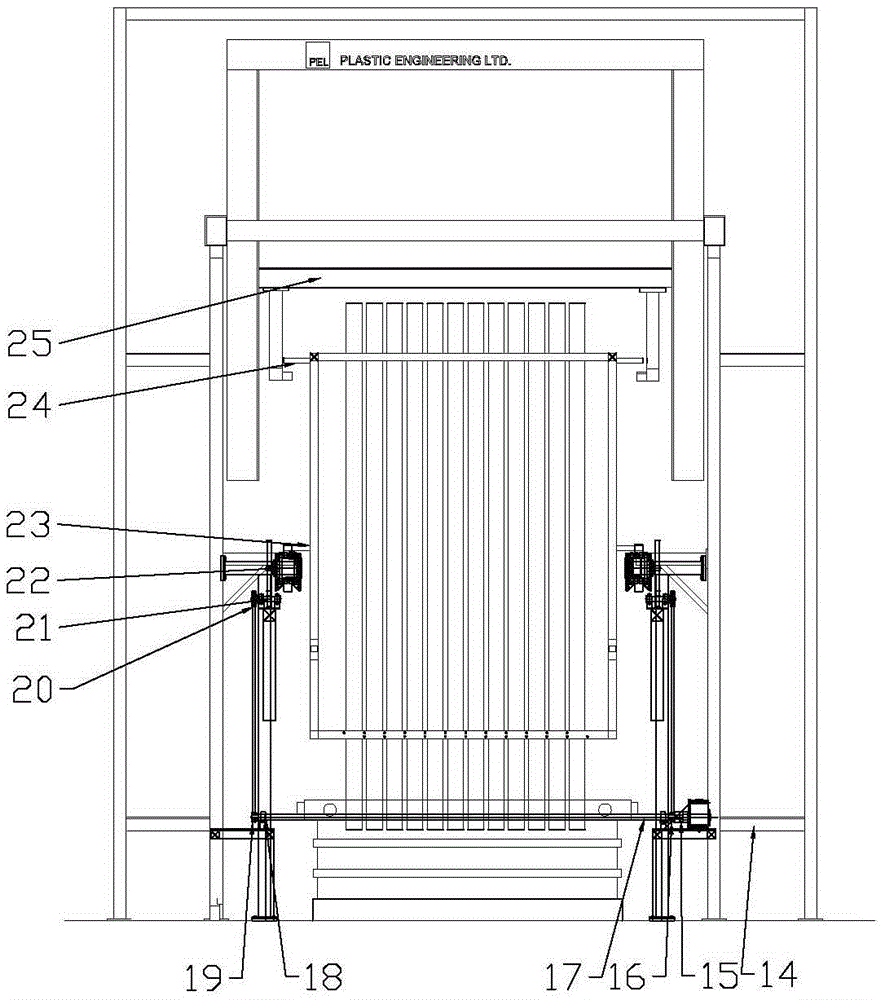

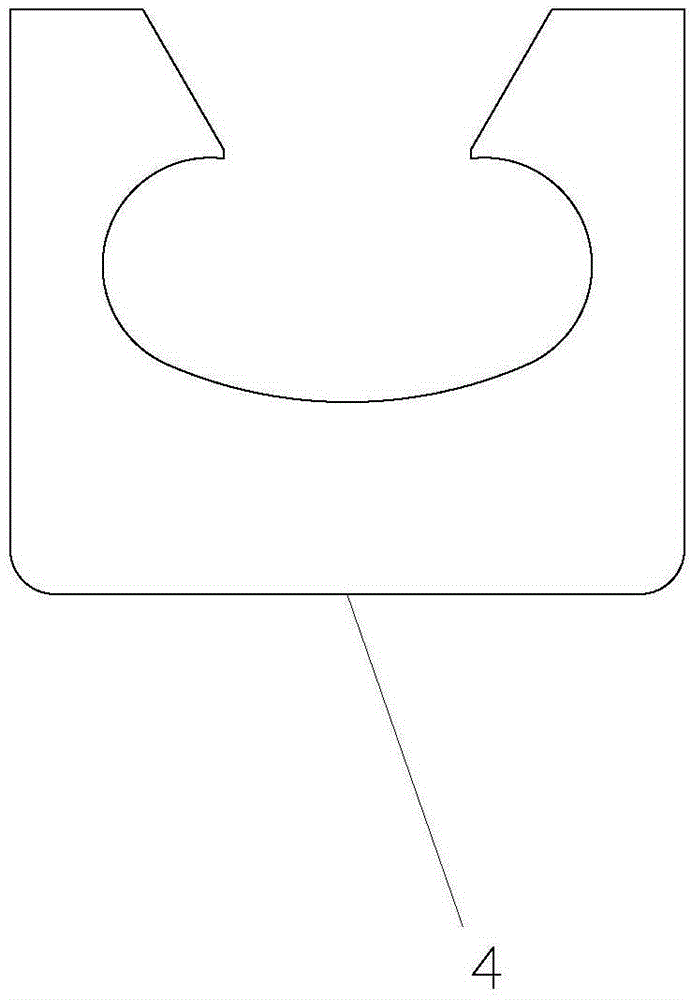

[0011] Below in conjunction with accompanying drawing, the present invention will be further described: figure 1 and figure 2 As shown, in the electroplating workpiece conveying mechanism of the present invention, its gantry trolley 5 is placed on the frame guide rail 6, the trolley can move horizontally along the frame guide rail 6, and the hook 25 can move up and down along the gantry trolley. The frame guide rail 6 is installed on the production line frame 14, the electroplating tank 1 is placed inside the production line frame 14, the workpiece 2 is installed on the hanger 3, and the middle sword hand 23 and the upper sword hand 24 are installed on the hanger 3. 3 is placed on the flying bus seat 4 through the middle sword hand 23, and the flying bus seat 4 is fixed on the production line frame 14 and the conveying chain 12. The shape of the flying bus seat is as image 3 As shown, it can be guaranteed that the conveyor chain 12 will not disengage from the flying bus se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com