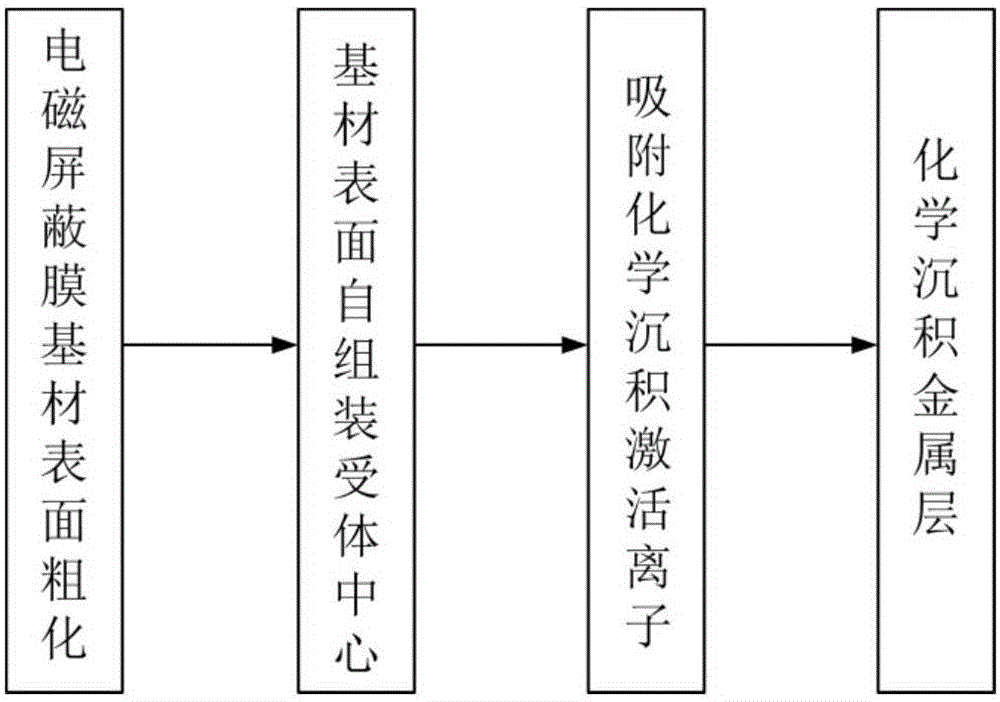

Preparation method of metal layer for electromagnetic shielding film

An electromagnetic shielding film and metal layer technology, which is applied in metal material coating process, coating, liquid chemical plating and other directions, can solve the problems of low preparation cost and inability to obtain a uniform and dense metal layer, and achieves low preparation cost, The effect of low production input cost and strong controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

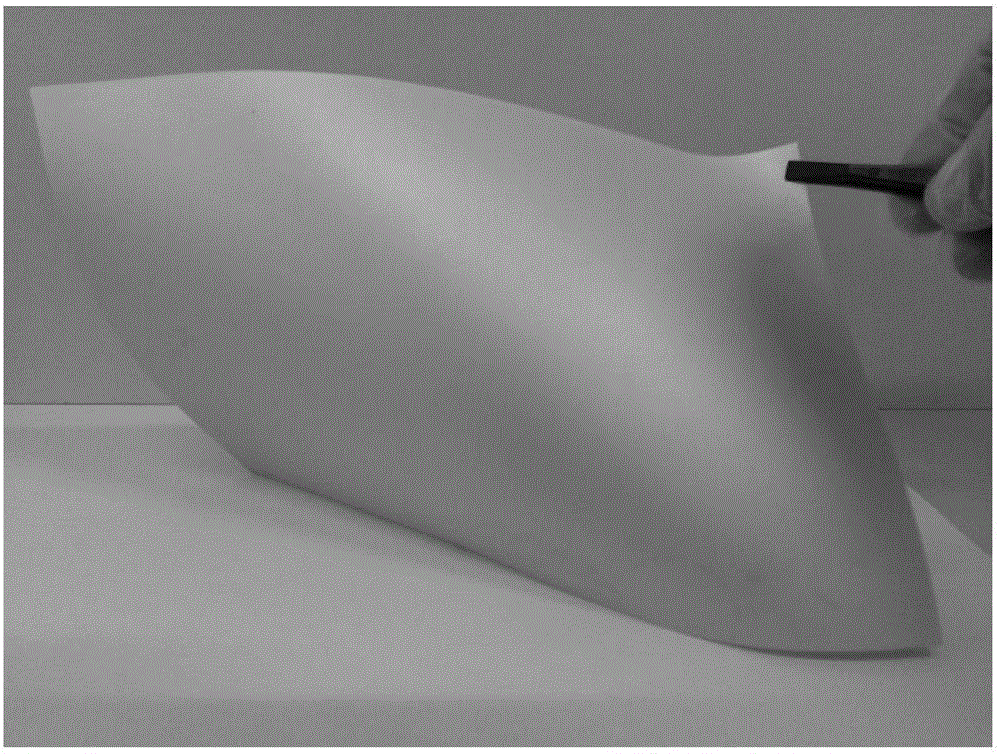

Examples

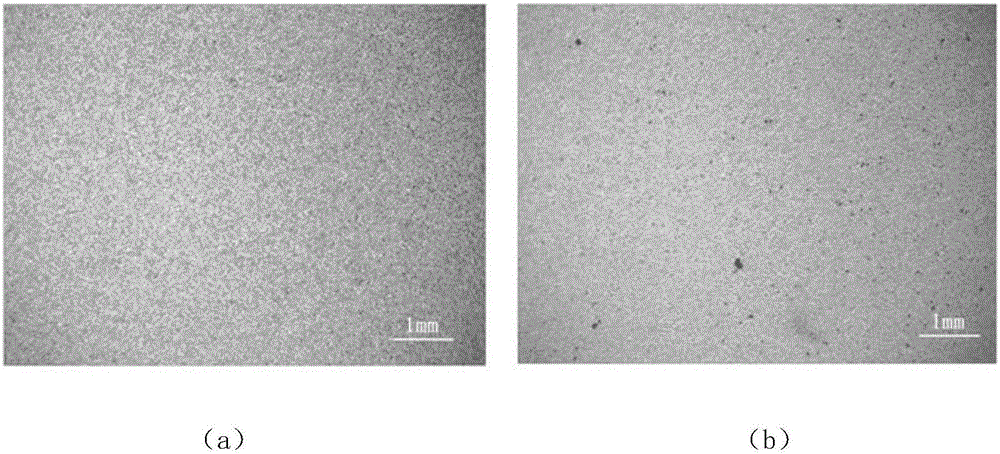

Embodiment 1

[0034]Step A: Prepare a permanganate solution with a concentration of 0.1mol / L and a pH value of 13, heat it and keep it at 40°C, and immerse the electromagnetic shielding film substrate in the permanganate solution for 5 minutes;

[0035] Step B: prepare 400ml of sodium thiosulfate solution with a concentration of 0.05mol / L as the acceptor center solution, heat the solution and keep the temperature at 60°C, immerse the roughened electromagnetic shielding film substrate in this solution for self-assembly treatment for 10 Minutes; the self-assembled substrate has a strong ion adsorption effect;

[0036] Step C: Using a mixture of deionized water, ethanol and ethylene glycol as a solvent, prepare a silver nitrate solution with a concentration of 0.03 mol / L, keep the temperature of the solution at 25°C, and self-assemble the base with the acceptor center The material is immersed in this solution to absorb chemical deposition activated ions, and the treatment time is 10 minutes. ...

Embodiment 2

[0040] Step A: Prepare a permanganate solution with a concentration of 0.1mol / L and a pH value of 13, heat it and keep it at 40°C, and immerse the electromagnetic shielding film substrate in the permanganate solution for 5 minutes;

[0041] Step B: Prepare 400ml of thiourea solution with a concentration of 0.05mol / L as the acceptor center solution, heat the solution and keep the temperature at 60°C, immerse the roughened electromagnetic shielding film substrate in this solution for self-assembly treatment for 10 minutes; The substrate after self-assembly has a strong ion adsorption effect;

[0042] Step C: Using a mixture of deionized water and ethanol as a solvent, prepare a silver nitrate solution with a concentration of 0.02mol / L, keep the solution at a constant temperature of 40°C, and immerse the self-assembled substrate with acceptor centers in this solution The treatment is to adsorb chemical deposition to activate ions, and the treatment time is 10 minutes.

[0043] S...

Embodiment 3

[0045] Step A: Prepare a permanganate solution with a concentration of 0.08mol / L and a pH value of 13, heat it and keep it at 40°C, and immerse the electromagnetic shielding film substrate in the permanganate solution for 5 minutes;

[0046] Step B: Using a mixture of deionized water, ethanol and ethylene glycol as a solvent, prepare a silver nitrate solution with a concentration of 0.03mol / L, keep the solution at a constant temperature of 25°C, and immerse the substrate treated in step A This solution is treated to adsorb chemical deposition activated ions, and the treatment time is 10 minutes.

[0047] Step C: preparing a chemical copper precipitation solution, the concentration of each component of the chemical copper precipitation solution is as follows: copper sulfate 0.04mol / L, nickel sulfate 0.008mol / L, formaldehyde 0.16mol / L, potassium sodium tartrate 0.08mol / L, B Disodium diamine tetraacetate 0.006mol / L, potassium ferrocyanide 20mg / L, bipyridine 10mg / L; heat and keep ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com