Method for preparing magnesium and magnesium alloy surface coating

A magnesium alloy and coating technology, which is applied in the field of preparation of magnesium and magnesium alloy surface coatings, can solve the problems of unsatisfactory coating effects, complicated procedures, and high costs, and achieve the effects of excellent performance, simplified procedures, and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

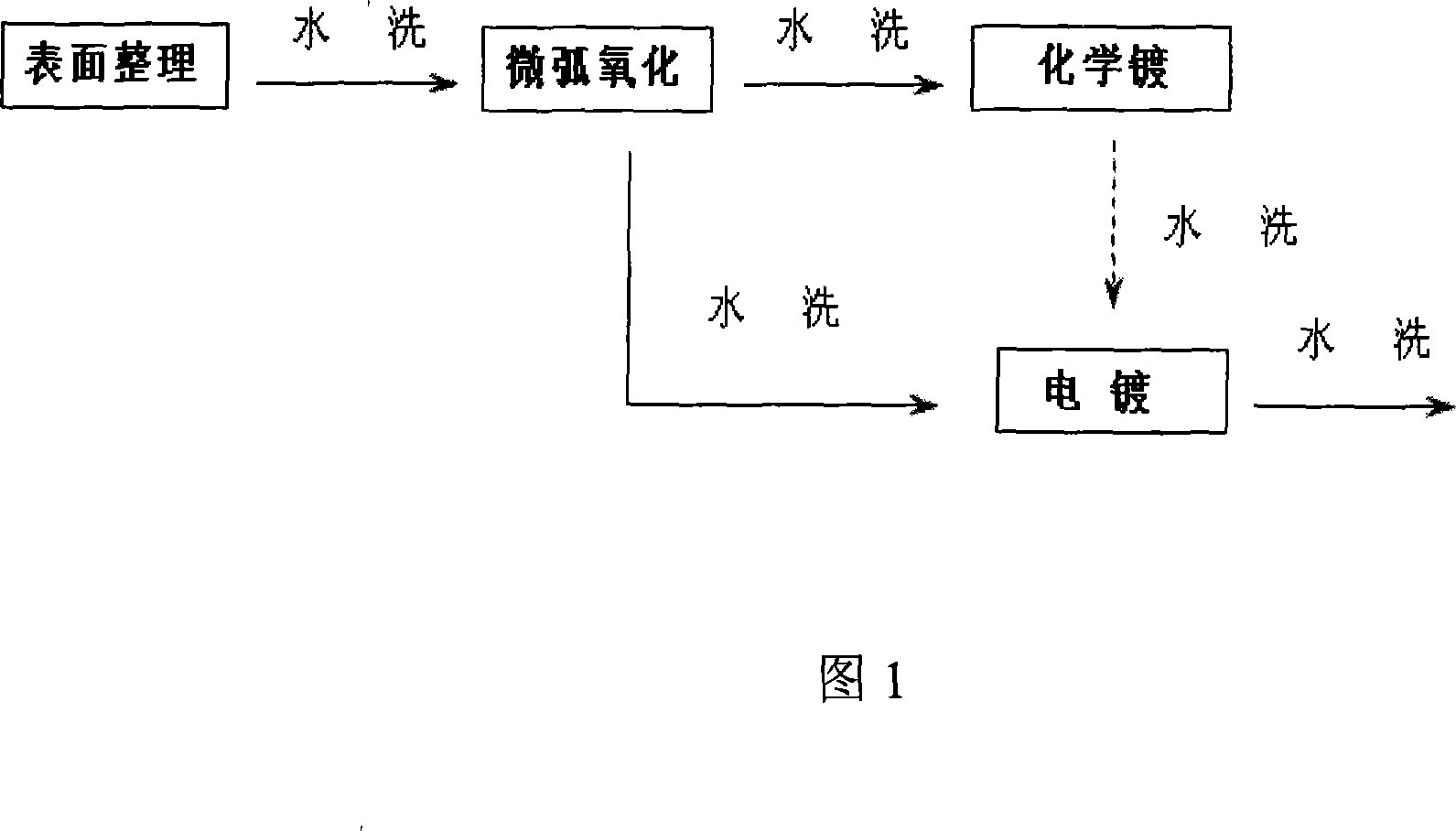

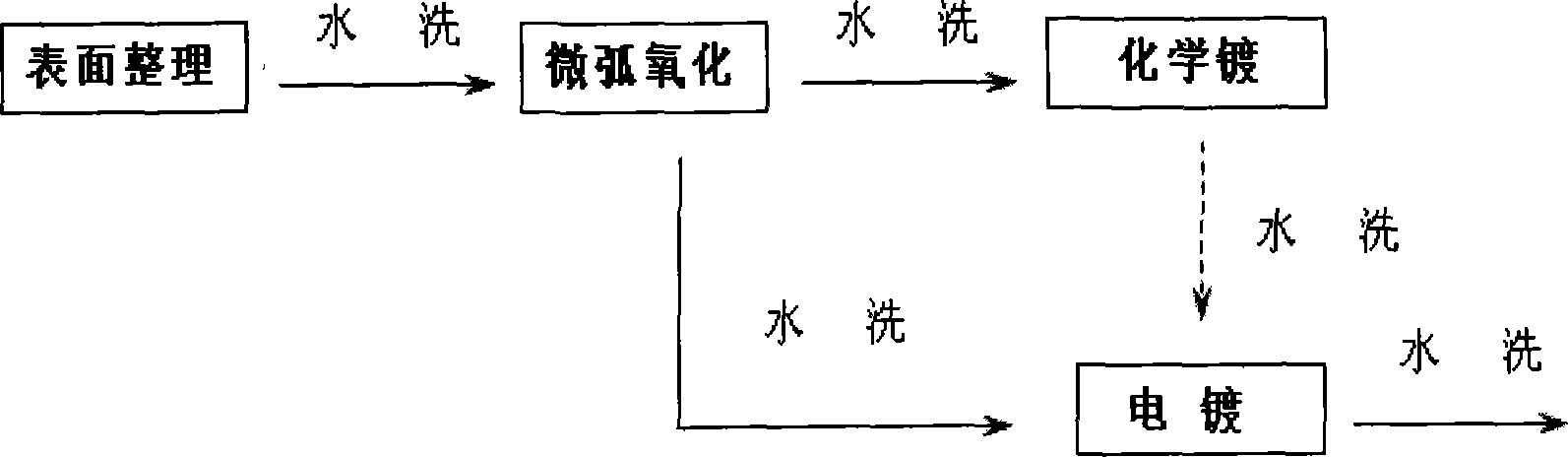

Image

Examples

Embodiment 1

[0029] Prepare 2L of NaF solution with distilled water at a concentration of 40g / L to obtain a micro-arc oxidation electrolyte. Prepare the electroless plating solution according to the formulation requirements of No. 01 plating process in Table 1, and adjust the pH value of the plating solution to 6.0. The AZ91D, AM60B and pure magnesium samples processed by wire cutting into 50mm×50mm×2mm were respectively polished with water sandpaper from coarse to fine until the appearance was uniform and smooth, and rinsed and scrubbed with absolute ethanol after connecting with the wire, and then rinsed with distilled water Then immersed in the micro-arc oxidation electrolyte at room temperature, and treated with sinusoidal alternating current constant voltage 200V micro-arc oxidation for 2 minutes. After taking it out, rinse it with tap water and distilled water in sequence, then immerse in the plating solution whose temperature is controlled at 80±2°C, and apply electroless plating fo...

Embodiment 2

[0032] Except that the micro-arc oxidation electrolyte was changed to 100g / L sodium phosphate solution, and the micro-arc oxidation condition was changed to a sinusoidal AC constant voltage of 150V for 60min, the others were the same as in Example 1.

[0033] A complete coating with a uniform, smooth appearance and a gray metallic sheen is obtained. OM and SEM carried out surface and cross-sectional observations, and found that the coating structure is dense and there are no obvious defects. According to GB / T13913-92 thermal shock test and file test, the results show that the bonding force is good.

Embodiment 3

[0035] Except that the micro-arc oxidation electrolyte was changed to 5g / L sodium fluoride and 20g / L sodium phosphate solution, and the micro-arc oxidation condition was changed to sinusoidal alternating current constant voltage 250V for a treatment time of 1min, the others were the same as in Example 1.

[0036] A complete coating with a uniform, smooth appearance and a gray metallic sheen is obtained. OM and SEM carried out surface and cross-sectional observations, and found that the coating structure is dense and there are no obvious defects. According to GB / T13913-92 thermal shock test and file test, the results show that the bonding force is good.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com