Process for producing nano deinsectization polyester fibers

A nano-insect-killing polyester and polyester fiber technology, applied in fiber processing, fiber types, textiles and papermaking, etc., can solve the problems of insufficient bonding, limited insect control effect on the human body, and ecological environment impact, and achieve excellent bonding. , the effect of not easy to reduce the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

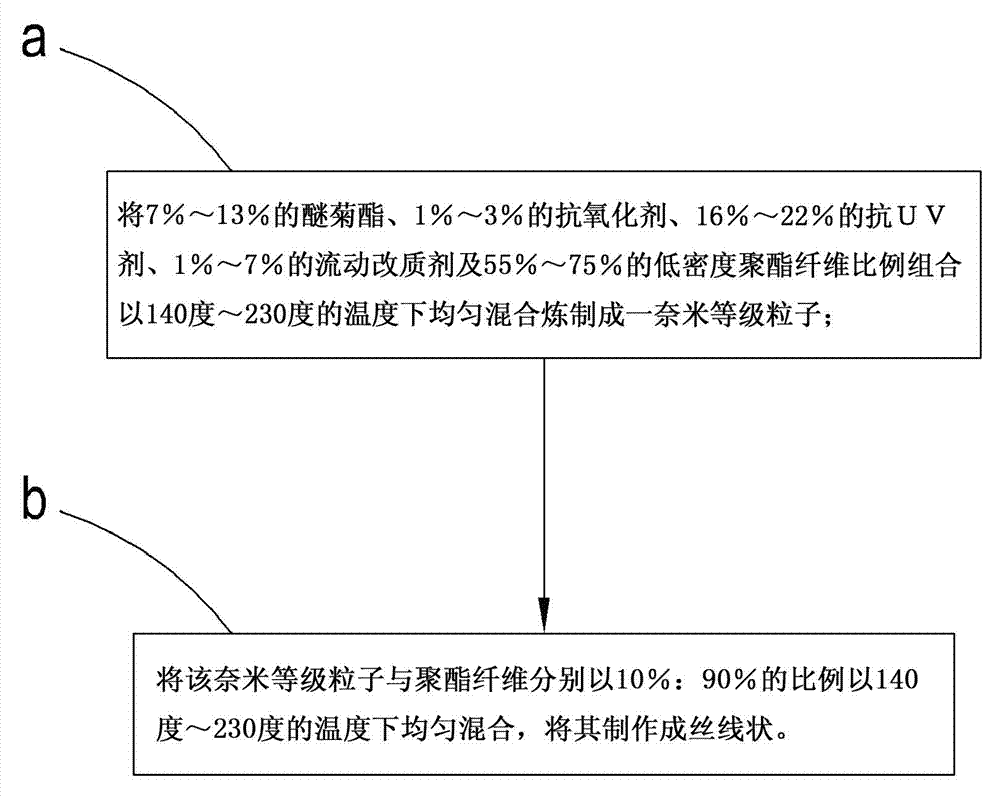

[0028] as attached figure 1 As shown in the figure, it is a schematic diagram of the manufacturing process of the preferred embodiment of the present invention. It can be clearly seen from the figure that the manufacturing process of the nano-insect-killing polyester fiber of the present invention includes the following steps:

[0029] (a) Mix 7%-13% etherethrin, 1%-3% antioxidant, 16%-22% anti-UV agent, 1%-7% flow modifier and 55%-75% The proportion of low-density polyester fibers is uniformly mixed and refined at a temperature of 140 to 230 degrees to make a nano-scale particle;

[0030] (b) The nanoscale particles and the polyester fibers are uniformly mixed at a temperature of 140 to 230 degrees at a ratio of 10%: 90%, respectively, to make them into a thread shape.

[0031] The optimum ratio of the etherethrin is 10%.

[0032] The optimum ratio of the antioxidant is 2%.

[0033] Among them, the optimal proportion of the anti-UV agent is 19%.

[0034] The optimum ratio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com