Bridge type concentric directly-reading testing and regulating meter

一种测调仪、桥式的技术,应用在桥式同心直读测调仪领域,能够解决易起下、不具有导向功能、无法实现单层直接测试等问题,达到提高测试精度、强适应性的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

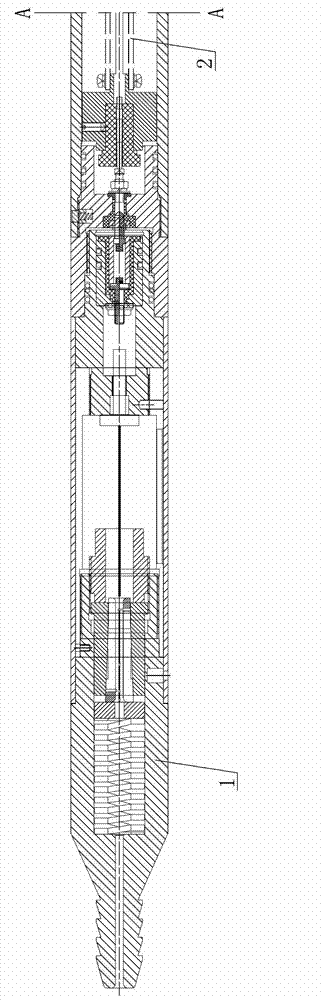

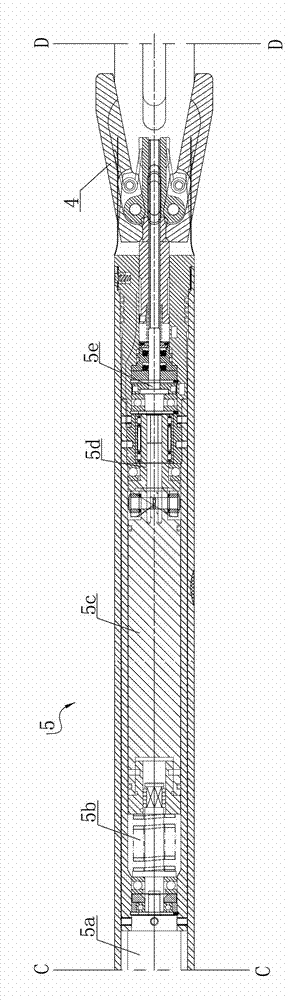

[0033] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention. Based on the embodiments of the present invention, all other embodiments obtained by persons of ordinary skill in the art without making creative efforts belong to the protection scope of the present invention.

[0034] The upper and lower positional relationship in this article is for the use state, specifically, one end of the cable head is up, and one end of the sealing bag is down.

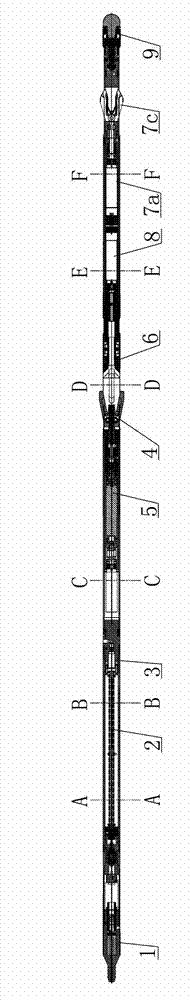

[0035] Such as Figure 1 to Figure 11As shown, the embodiment of the present invention proposes a bridge-type concentric direct-reading measuring and adjusting instrument, which includes a cable head 1, a circuit board 2, a pressure sensor 3, a supporting mechanism 4, an inclined shaft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com