Controlling method of gasoline direct injection engine optimal ignition angular advance

A technology of ignition advance angle and gasoline direct injection, which is used in engine ignition, spark ignition controller, automatic control and other directions, and can solve the problem that the ignition advance angle is not optimal.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

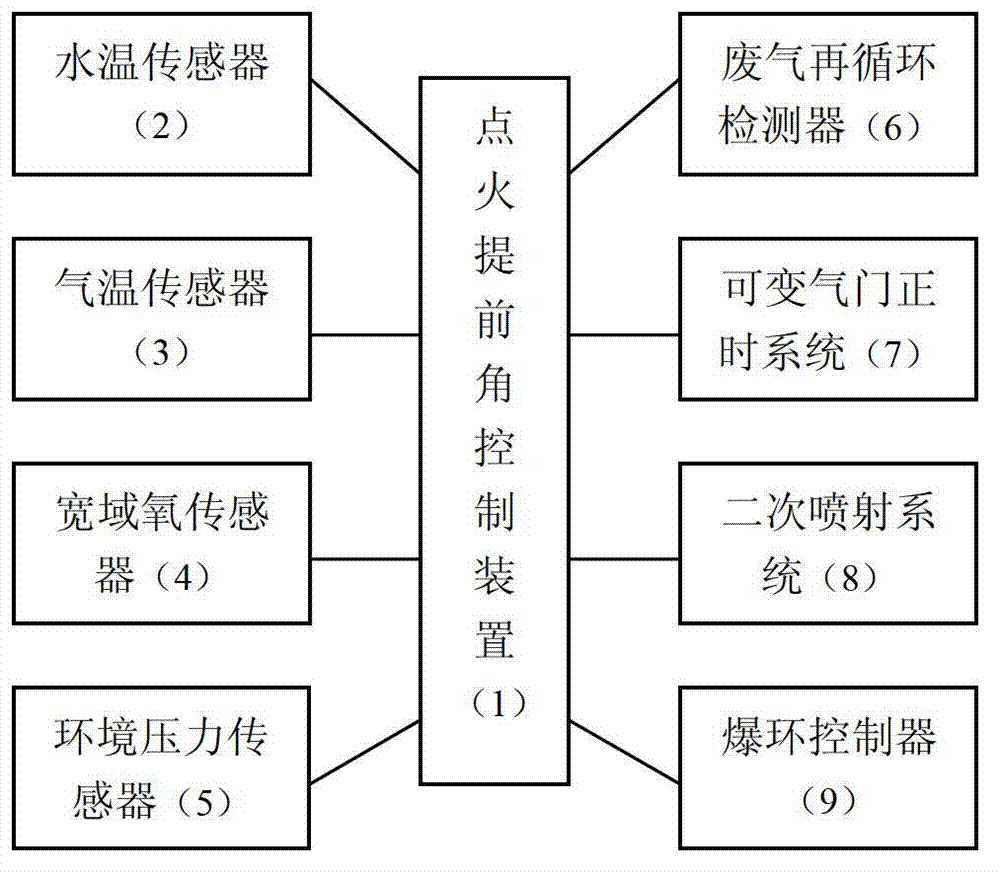

[0027] Embodiment: A kind of control method of gasoline direct injection engine optimum ignition advance angle, the process that optimum ignition advance angle is obtained is: after setting base ignition advance angle, by measuring eight factors, then according to these eight factors The influence of the basic ignition advance angle is calculated and corrected in turn, and the specific process is as follows:

[0028] The first step is to set the basic ignition advance angle;

[0029] The second step is to correct the basic ignition advance angle according to the influence of the engine inlet and outlet water temperature: when the engine inlet and outlet water temperature is relatively low, the temperature in the combustion chamber is also relatively low, the oil and gas mixing is relatively poor, and the combustion rate Decrease, the knocking tendency of the engine is weak, increase the ignition advance angle at this time, when the temperature of the inlet and outlet water of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com