Liquid pump with axial thrust washer

一种止推垫圈、液压泵的技术,应用在用于弹性流体的泵送装置的部件、泵、泵元件等方向,能够解决限制使用寿命等问题,达到延长使用寿命、确保固定的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

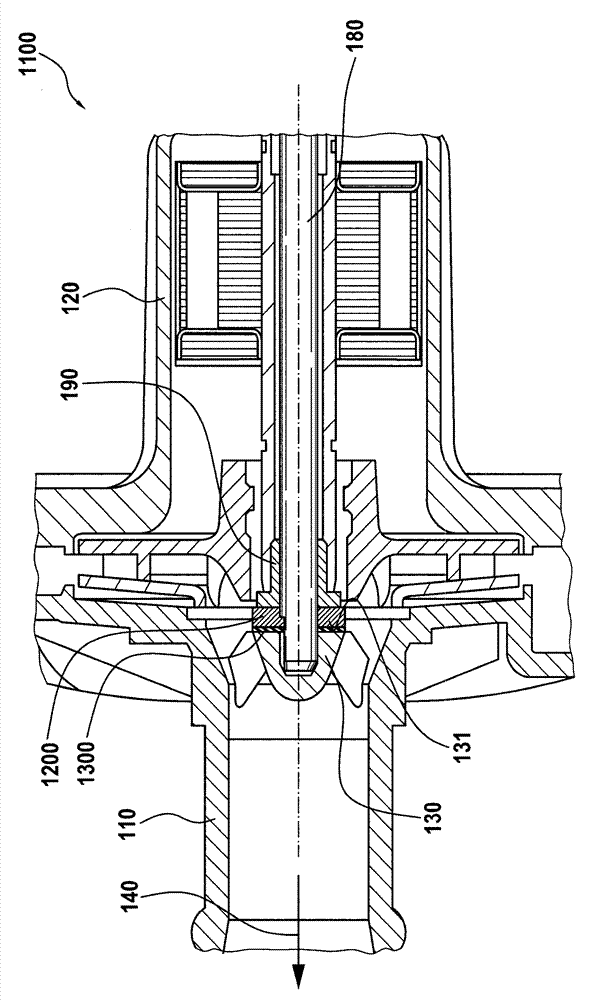

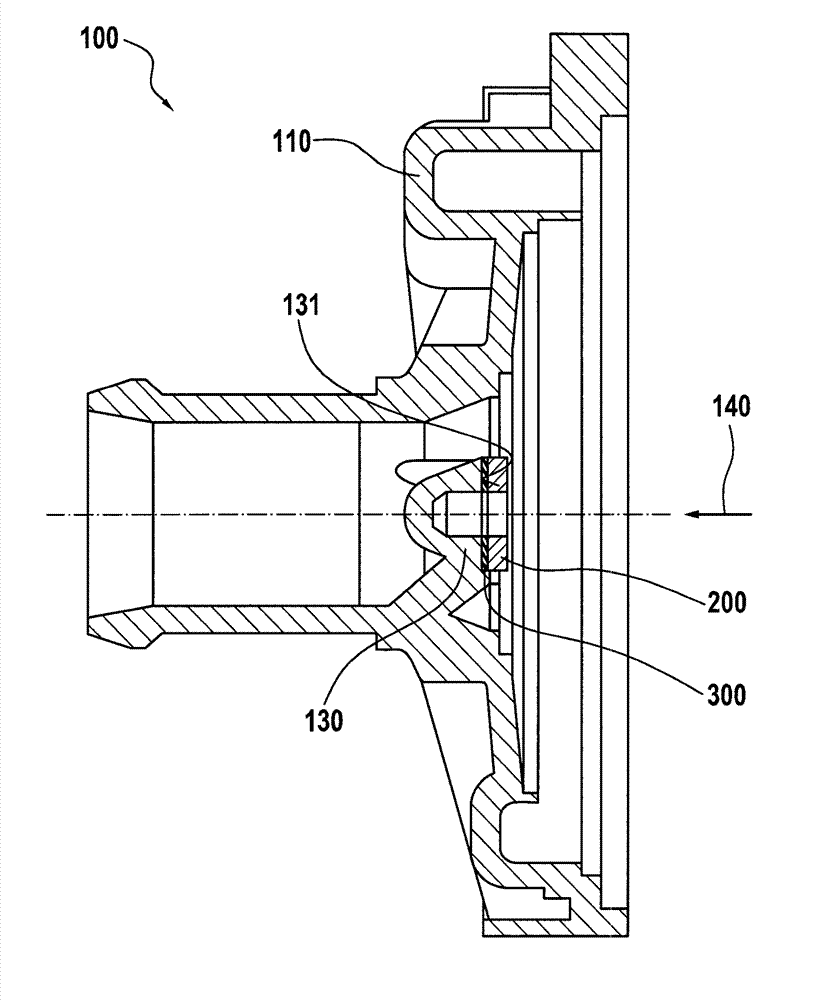

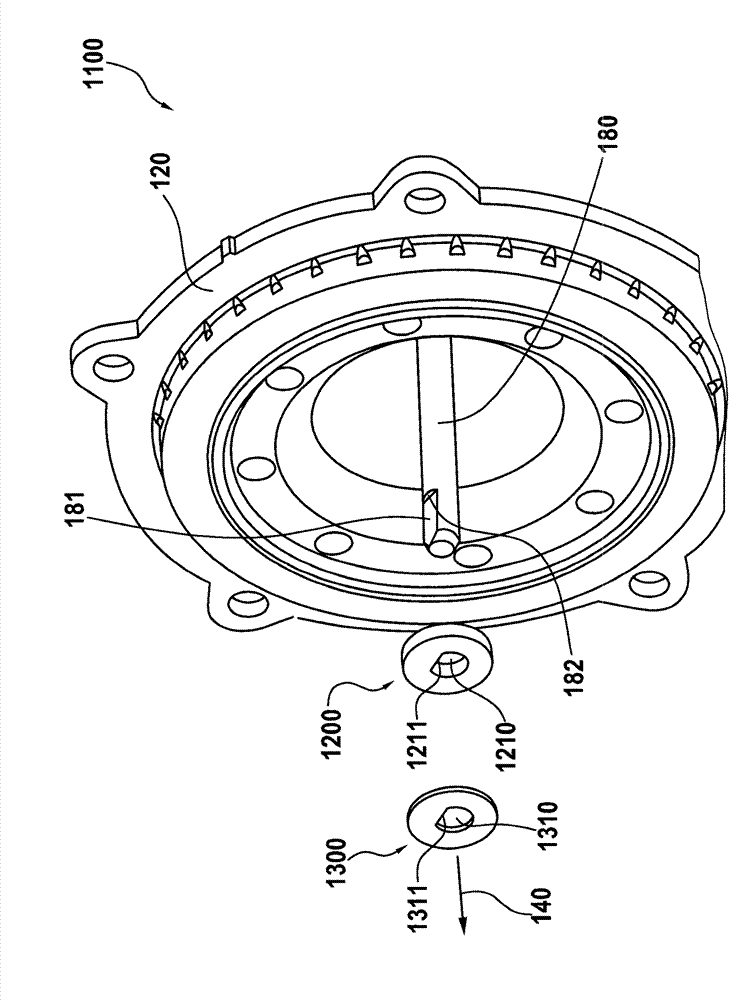

[0023] FIG. 1 is a cross-sectional view of a portion of a pump housing 110 of a hydraulic pump 100 . For example, hydraulic pump 100 may be designed to pump water. Hydraulic pump 100 can be used, for example, as a supplementary water pump in a motor vehicle. As a supplemental water pump, hydraulic pump 100 may be used to cool charge air, a battery of a controller, or other components of a motor vehicle.

[0024] The pump housing 110 has an axial bearing receptacle 130 which is designed to receive a bearing cover screw (not shown in FIG. 1 ). The bearing cap bolts extend in the axial direction 140 into the axial bearing receptacle 130 . Bearings, for example bearing shells, are mounted on the bearing cap bolts, which rotate around the bearing cap bolts during operation of the hydraulic pump 100 .

[0025] The axial bearing receptacle 130 has a bearing surface 131 which is oriented in the direction of the rotating bearing. In order to protect the bearing surface 131 of the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com