Locking device for ball screw

A technology of ball screw and locking device, which is applied in the direction of transmission device, belt/chain/gear, mechanical equipment, etc. It can solve the problems of not being able to meet the requirements, and cannot guarantee the safety of pilots, etc., and achieve good results and solve the self-locking function. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

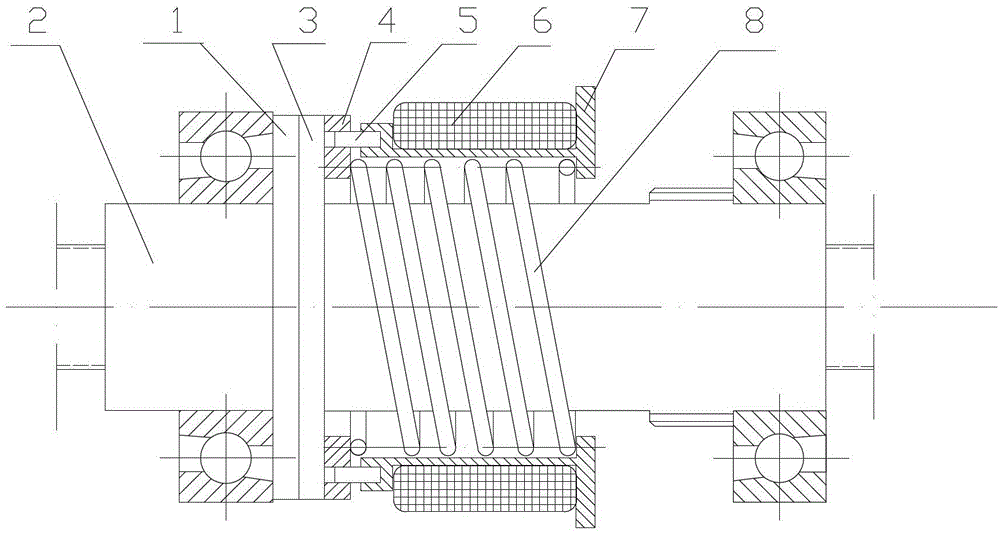

[0007] As shown in the figure, the locking device of the ball screw includes a housing 7, a coil 6, a screw nut 2, a brake disc 4, and a pressure spring 8. The coil 6 is installed on the housing 7, and a pressure spring is provided inside the housing 7. Spring 8, the housing 7 is also equipped with a brake disc 4 that can move along the guide pin 5 through the guide pin 5, the axis of the brake disc 4 coincides with the axis of the ball screw, and the pressure spring 8 One end is pressed on the housing 7, and the other end is pressed on the brake disc 4. The end surface of the nut 2 of the ball screw is provided with a friction disc 1, and the end face of the brake disc 4 is provided with a friction disc with the end face of the nut 2. 1 corresponds to the friction disc 3.

[0008] In use, the coil 6 is connected in series with the motor of the electric mechanism. When the power is turned on, the coil 6 generates a magnetic field, and the brake disc 4 moves along the guide pin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com