Drying equipment for circuit board blower

A technology for drying equipment and circuit boards, which is applied in drying, drying machines, lighting and heating equipment, etc., and can solve problems such as uneven temperature, inability to realize adjustment functions, and lack of temperature sensing functions for suction and exhaust fans. Achieve the effect of improving cleanliness and avoiding excessive fluctuations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further introduced below through a specific circuit board blast drying equipment.

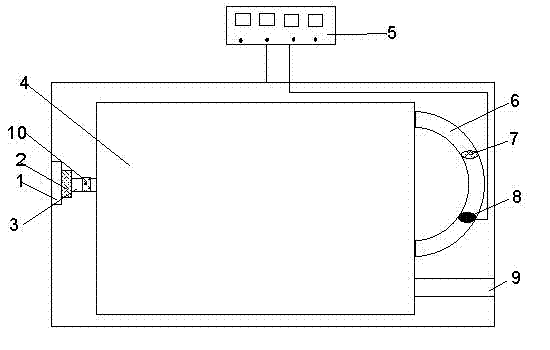

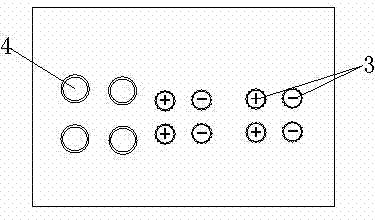

[0025] A circuit board blast drying equipment, comprising an air inlet 1, an air passage 3, an air inlet filter 2, a heater 7, a circulating air duct 6, an air duct filter 8, an air outlet 9, a drying chamber 4, a temperature The air inlet is equipped with an air intake filter 2, the air intake filter 2 is connected to the air passage 3, the other end of the air passage 3 is connected to the drying chamber 4, the drying chamber 4 is connected to the circulating air duct 6, and the middle of the circulating air duct 6 An air duct filter 8 and a PTC ceramic heater 7 are provided. The filter medium of the air duct filter 6 is a metal mesh or asbestos net with a temperature resistance above 200° C., and the temperature of the drying chamber is controlled by controlling the heater through a temperature controller.

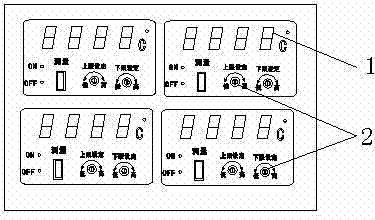

[0026] A temperature display screen 11 and a te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com