A composite torsion test device and method for components

An experimental device and component technology, which is applied in the direction of applying stable torsion to test the strength of materials, etc., can solve the problems of difficult experiment, complicated experimental method, high finishing cost, etc., and achieve simple operation and control of the experimental process, experimental operation and control The effect of simplicity, operation and control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

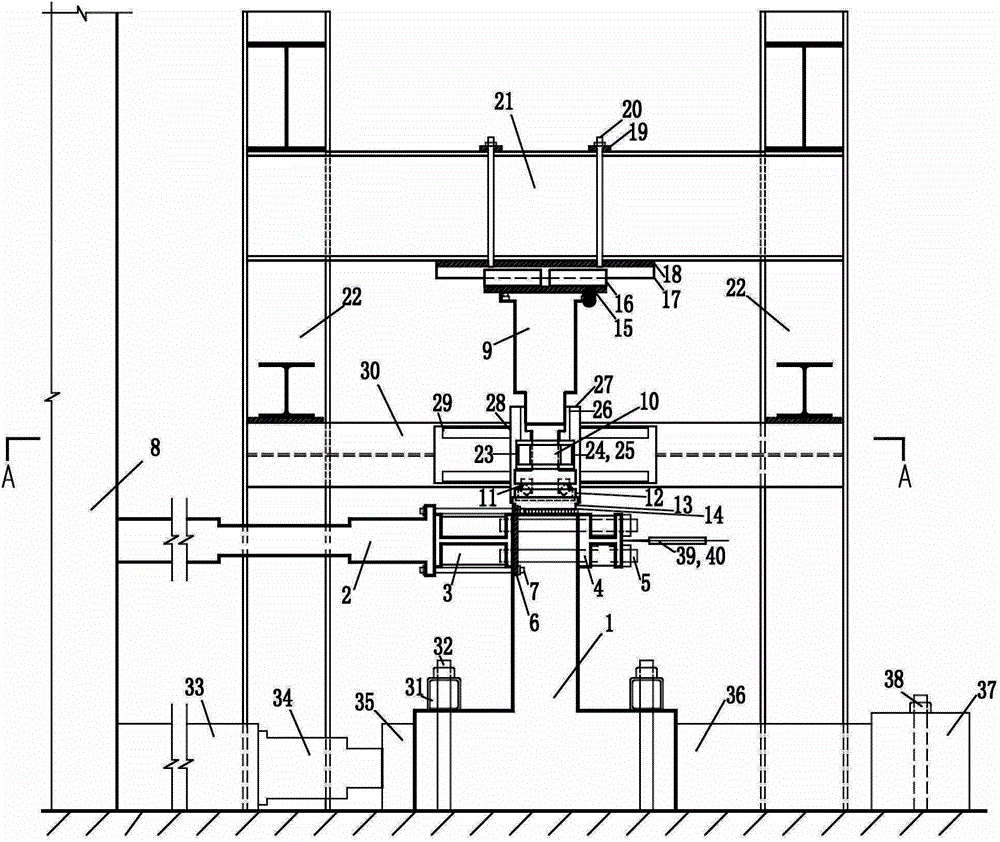

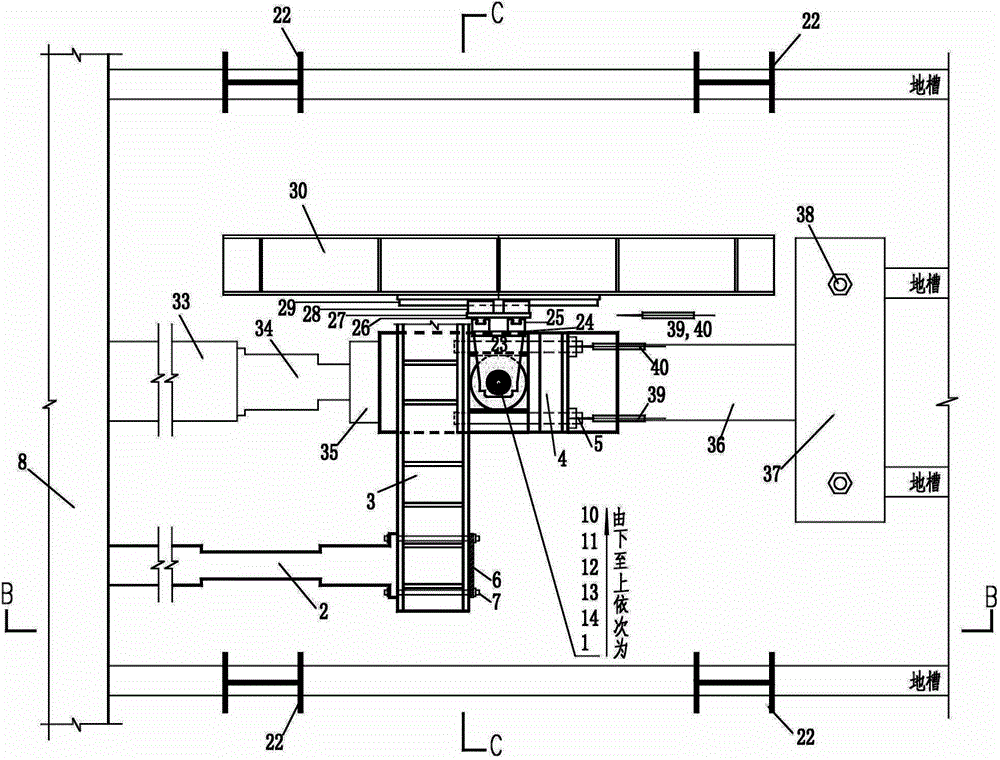

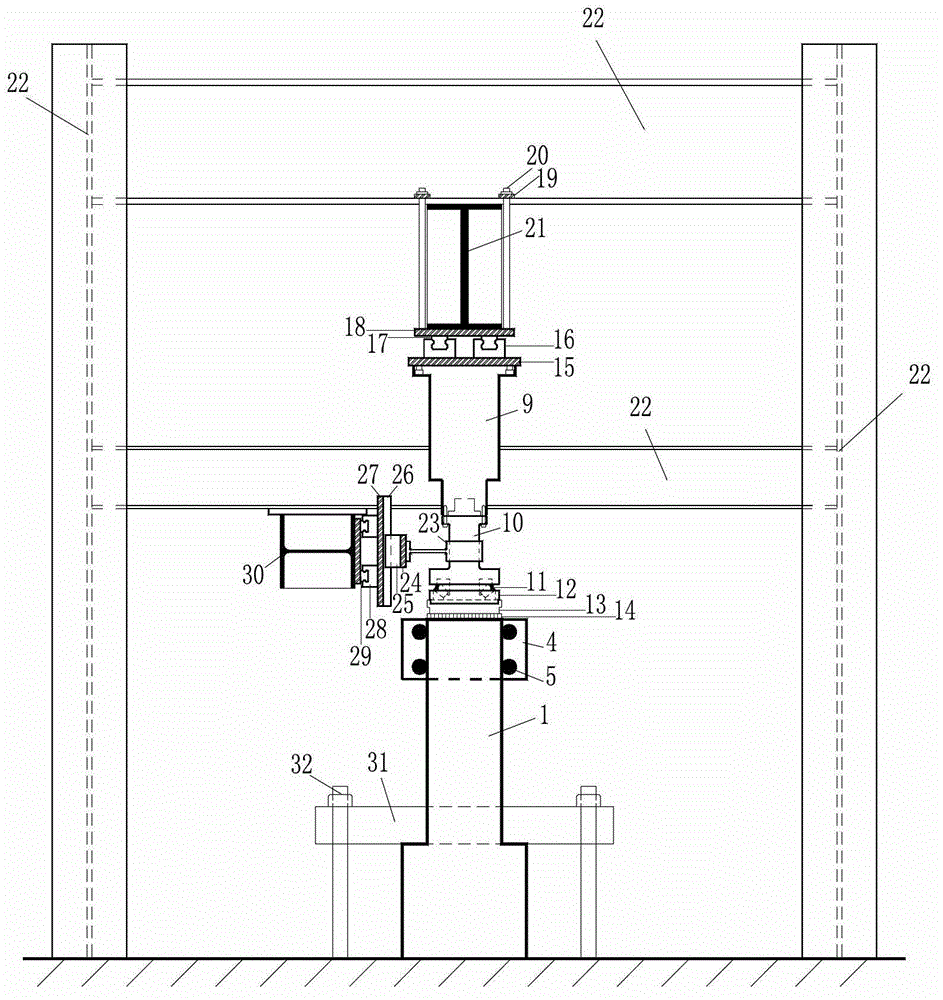

[0071] This embodiment provides an experimental device for compound torsion of structural members, and carried out the combined torsion experiment of compression bending, shear and torsion of 30 steel concrete members, and its structure is as follows figure 1 , figure 2 , image 3 As shown, it includes a horizontal force actuator 2, a loading beam 3, a clamping beam 4, a bolt 5 connecting the loading beam and the clamping beam, a steel plate 6 connecting the horizontal force actuator and the loading beam, and a bolt connecting the horizontal force actuator and the loading beam 7. Reaction wall 8. Vertical force jack 9. Adapter shaft connecting vertical force jack and thrust roller bearing 10. Thrust roller bearing 11. Mounting sleeve for the lower part of thrust roller bearing 12. Pressure bearing plate 13. Rubber pad 14, steel plate 15 connecting the vertical force jack and the slide block, slide block 16, guide rail 17, steel plate 18 for installing the guide rail, st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com