Ducts and condensate edge film collection and discharge devices for installation therein

A technology for exporting devices and condensate, which is applied in the field of pipelines, and can solve problems such as aggravation, failure to reach the minimum speed of condensate, and small outlet

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

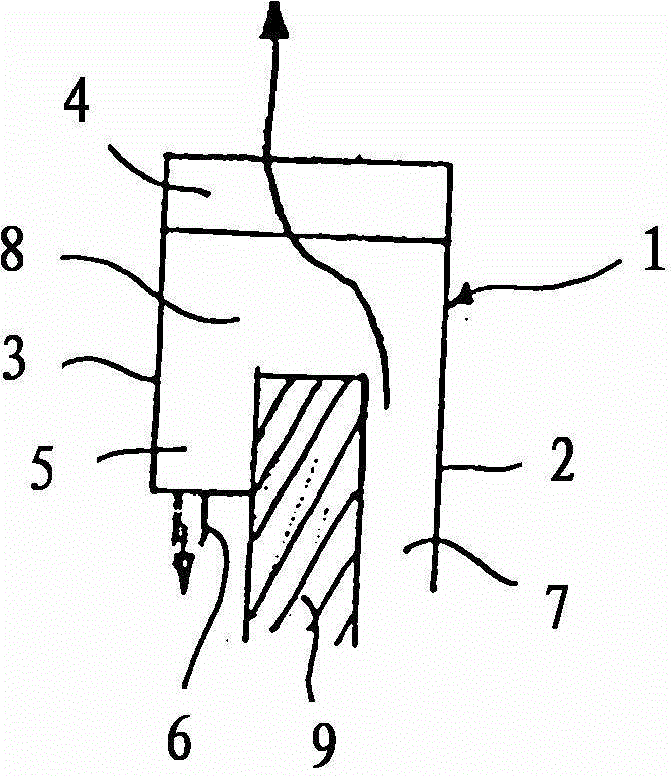

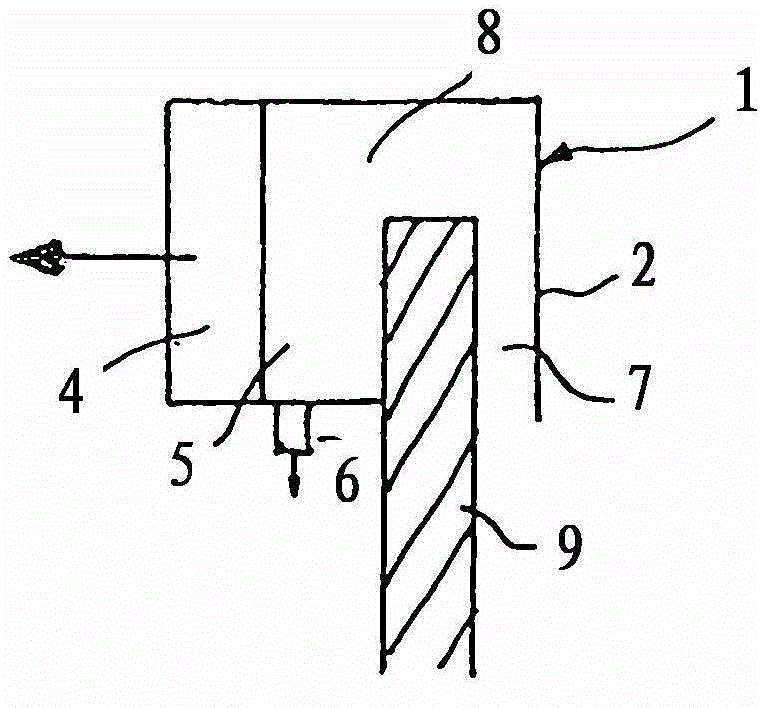

[0033] exist figure 1 The end wall of the wet chimney mouth is marked with 9 in the schematic vertical cross-sectional view of . The condensate edge film collection and discharge device 1 is schematically shown at the wet chimney mouth. The device has a separating element 2 which is annular and extends from the outside to the inside of the chimney. An annular space 7 is formed between the separating element 2 and the chimney wall 9 in such a way that it extends to a larger annular space 8 between the annular boundary wall 3 and the separating element 2 . figure 1 The gas flow direction is from bottom to top. A droplet separator in the form of an annular separator 4 in the direction of gas flow, likewise located between the separating element 1 and the dividing wall 3 , is arranged downstream of the annular space 8 . A condensate collection annular space 5 with a condensate drain 6 is located on the outside of the chimney wall 9 below the annular space 8 .

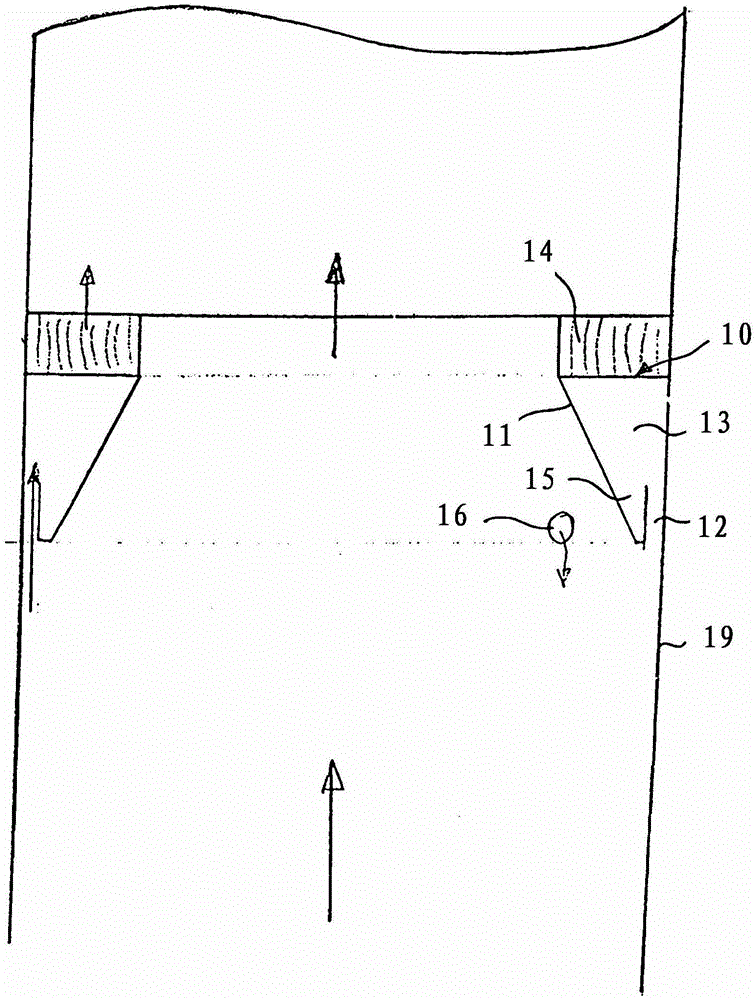

[0034] The cond...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com