An energy-saving and environment-friendly building bricklaying production device

An energy-saving, environment-friendly, and production-device technology, which is applied to supply devices, unloading devices, molding heads, etc., can solve problems such as increasing the production cost of bricklaying of various styles, being unable to effectively meet market demands, and unable to allow raw materials to enter the molding cavity, etc. Achieve the effect of preventing diffusion, reducing waste, and ensuring the degree of molding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

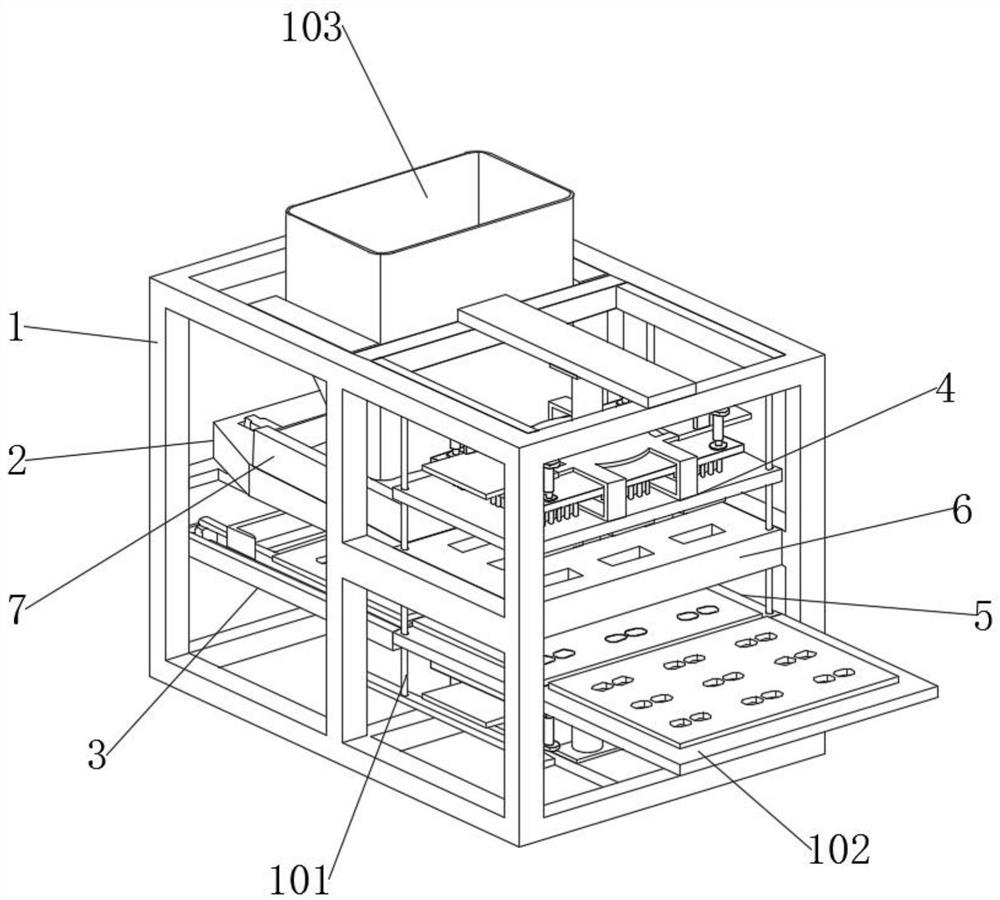

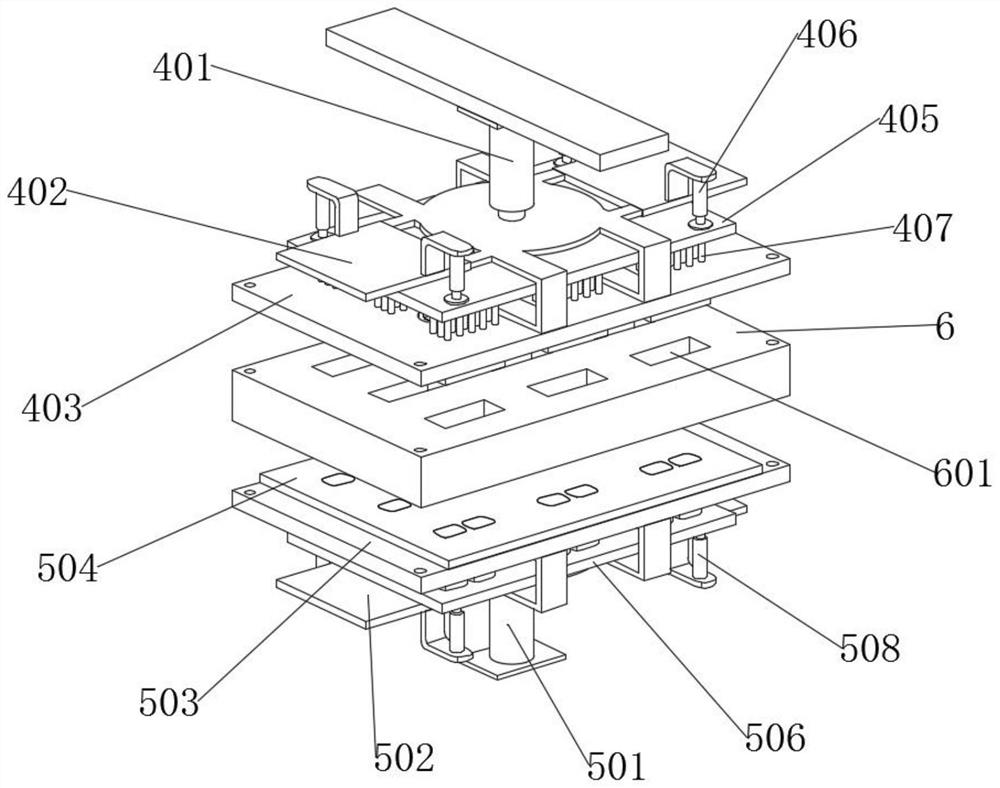

[0060] refer to Figure 1 to Figure 5 and Figure 8 to Figure 11 , an energy-saving and environment-friendly building bricklaying production device of the present embodiment, comprising a fixed frame 1; The material mechanism 3, the middle part of the front end of the fixed frame 1 is fixedly connected with the forming plate 6 and the holding plate 102, the forming plate 6 is located at the rear side of the holding plate 102, and the forming plate 6 is provided with uniformly distributed forming through holes 601, the four corners of the forming plate 6 Both are fixedly connected with a guide post 101 , the upper end of the guide post 101 is slidably provided with an upper pressing block mechanism 4 , and the lower end of the guide post 101 is slidably provided with a lower platen mechanism 5 .

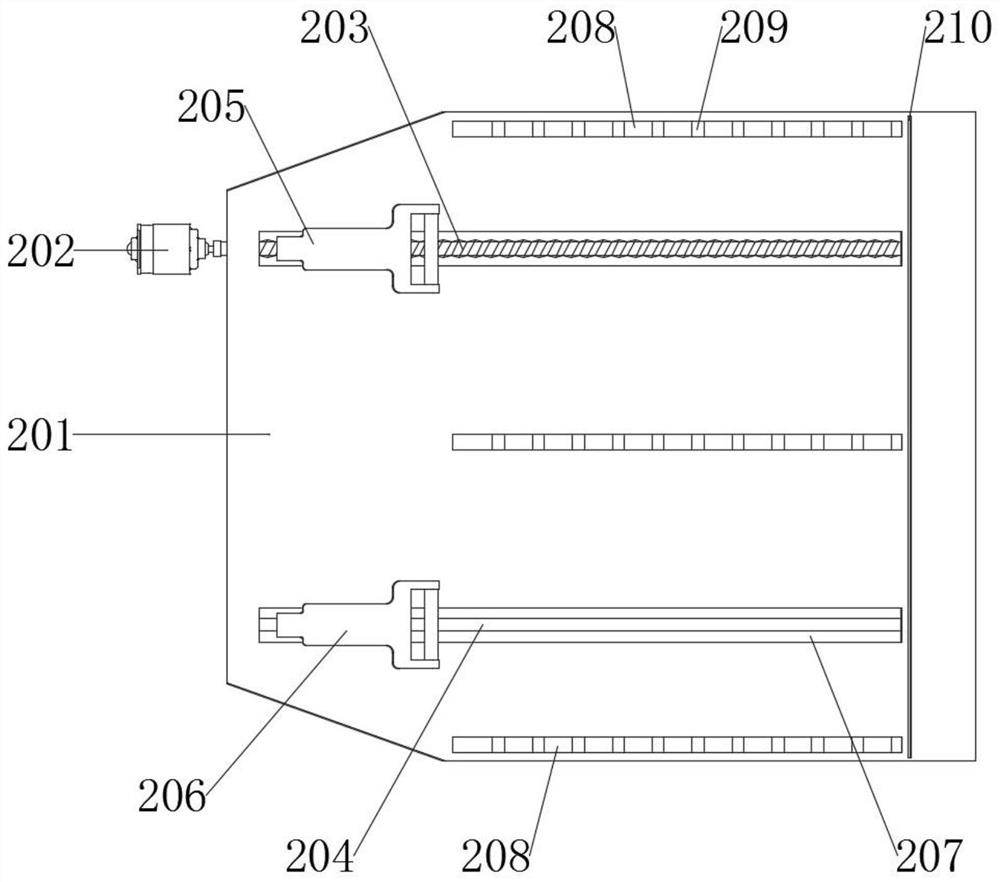

[0061] Specifically, refer to figure 1 and Figure 3 to Figure 5 , the feeding mechanism 2 includes a feeding plate 201, a feeding motor 202, a feeding screw 203, a feeding guide r...

Embodiment 2

[0078] Such as Figure 1 to Figure 11 As shown, the parts that are the same as or corresponding to those in the first embodiment are marked with the corresponding reference numerals in the first embodiment. For the sake of simplicity, only the differences from the first embodiment are described below. The difference between this embodiment two and embodiment one is: as Figure 6 and Figure 7 As shown, the lower end surface of the conveying box 7 is provided with a uniformly distributed No. 1 material penetration hole 704, and the inner lower end of the conveying box 7 is provided with a material stopper 705, and the rear end of the material stopper 705 is fixedly connected with a material stopper 706, and the front end of the material stopper 705 Go out conveying box 7, and be connected with conveying box 7 slidingly, offer No. 2 material penetration hole 707 on the material retaining plate 705, limit spring 708 is fixedly connected with the left and right sides of material ...

Embodiment 3

[0082] Such as Figure 1 to Figure 5 and Figure 8 to Figure 13 As shown, the parts that are the same as or corresponding to those in the first embodiment are marked with the corresponding reference numerals in the first embodiment. For the sake of simplicity, only the differences from the first embodiment are described below. The difference between this embodiment two and embodiment one is: as Figure 12 to Figure 13 As shown, the middle part of the lower end of the lower pressing plate 503 is affixed with evenly distributed lower supporting springs 505, and the lower pressing plate 503 and the receiving plate 504 are provided with through grooves corresponding to the forming through holes 601, and the lower end of the lower supporting spring 505 is affixed with a The lower forming plate 506 is located between the lower fixing frames 502, and the upper end of the lower forming plate 506 is fixedly connected with a forming block 507 corresponding to the through groove, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com