Oil immersion device of transformer

A transformer and oil immersion technology, which is applied to the surface coating device, inductance/transformer/magnet manufacturing, electrical components, etc., can solve the problems of low precision, liquid surface tumbling, complicated operation, etc., to ensure correctness The effect of smoothness and leveling of the liquid surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

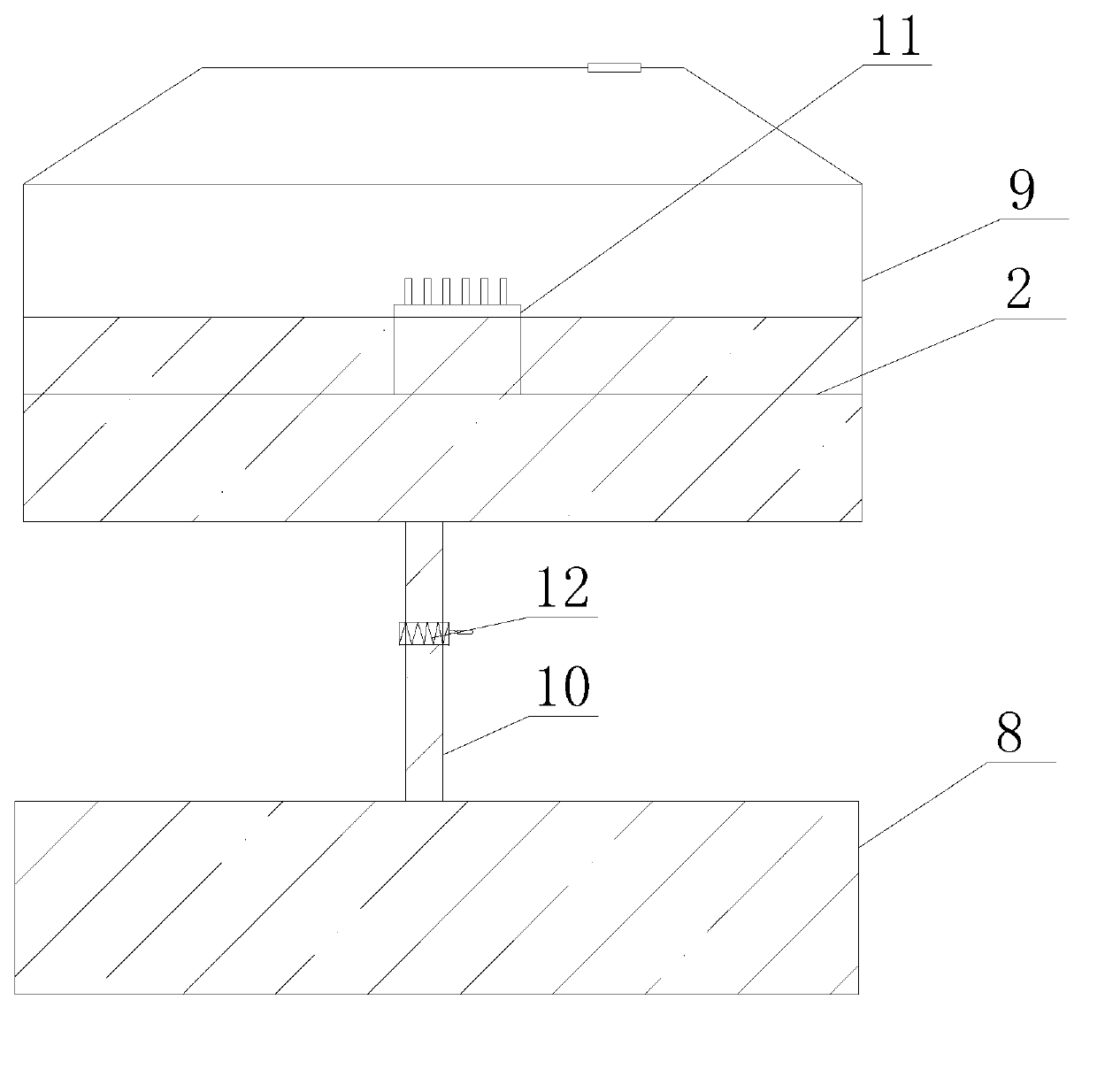

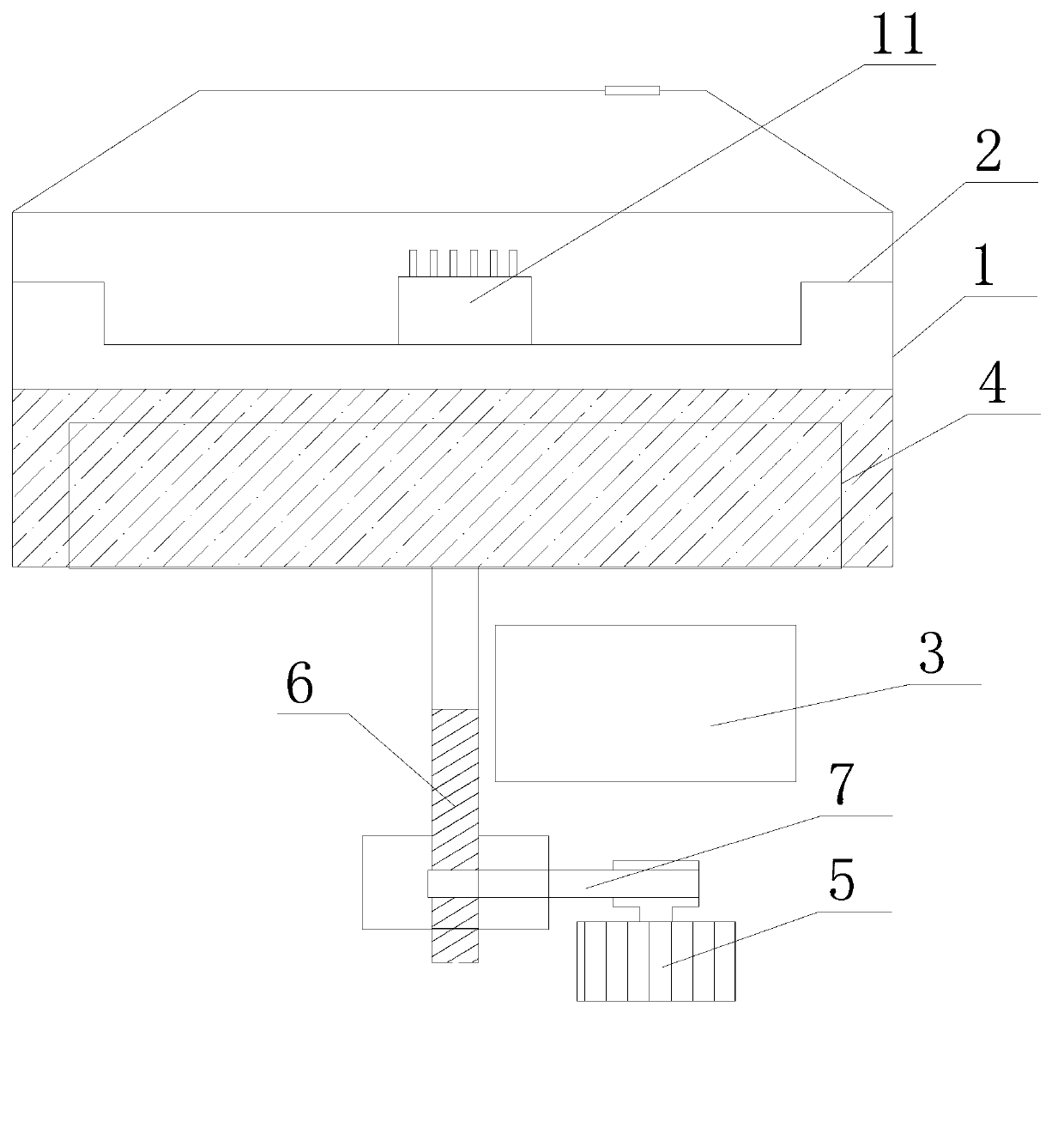

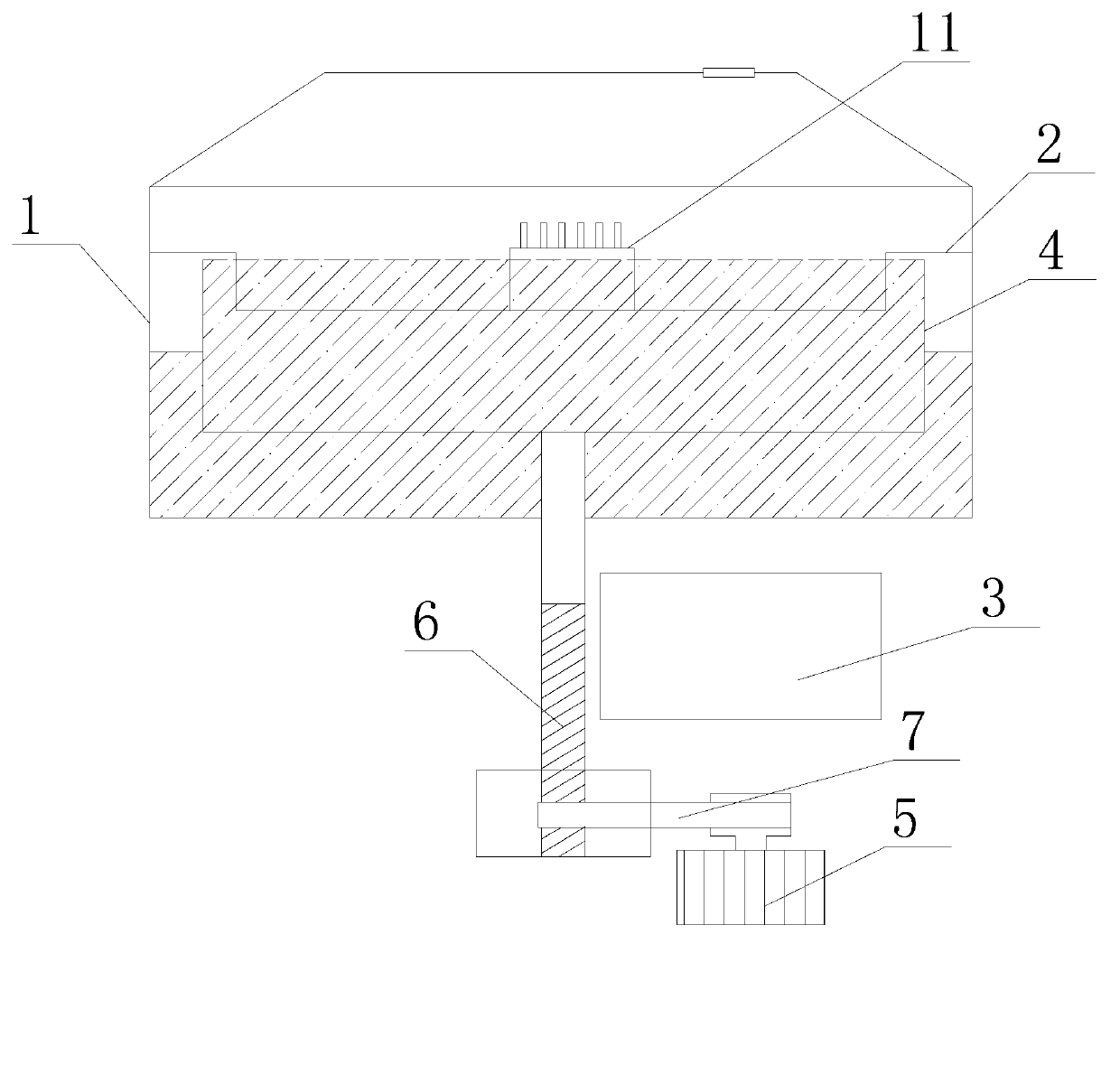

[0014] Such as figure 2 , image 3 As shown, the oil immersion device of the transformer according to the present invention includes an oil tank 1, a support 2 and a PLC control system 3 fixed in the oil tank 1 with a downwardly recessed middle part, and a recessed part is set in the middle part of the support 2 for shelving the transformer 11. The edge is higher than where the transformer 11 is located, and the upper edge of the sub-slot 4 will not touch the support 2 when it rises, so that the transformer 11 can be located in the sub-slot 4 and contact the insulating oil. Because the PLC control system 3 has no requirements on the position, it can be set at any position that can be placed. Described oil groove 1 is provided with sub-groove 4, and sub-groove 4 is positioned at the below of support 2, and the outer side of oil groove 1 is p...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap