Power transmission mechanism used for sand filling machine

A technology of power transmission and sand filling machine, which is applied in the field of power transmission mechanism, can solve the problems of entanglement of air supply lines, affecting the normal operation of equipment, etc., and achieves the effects of reliable positioning, reduction of waste of sand filling, and high precision of sand filling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

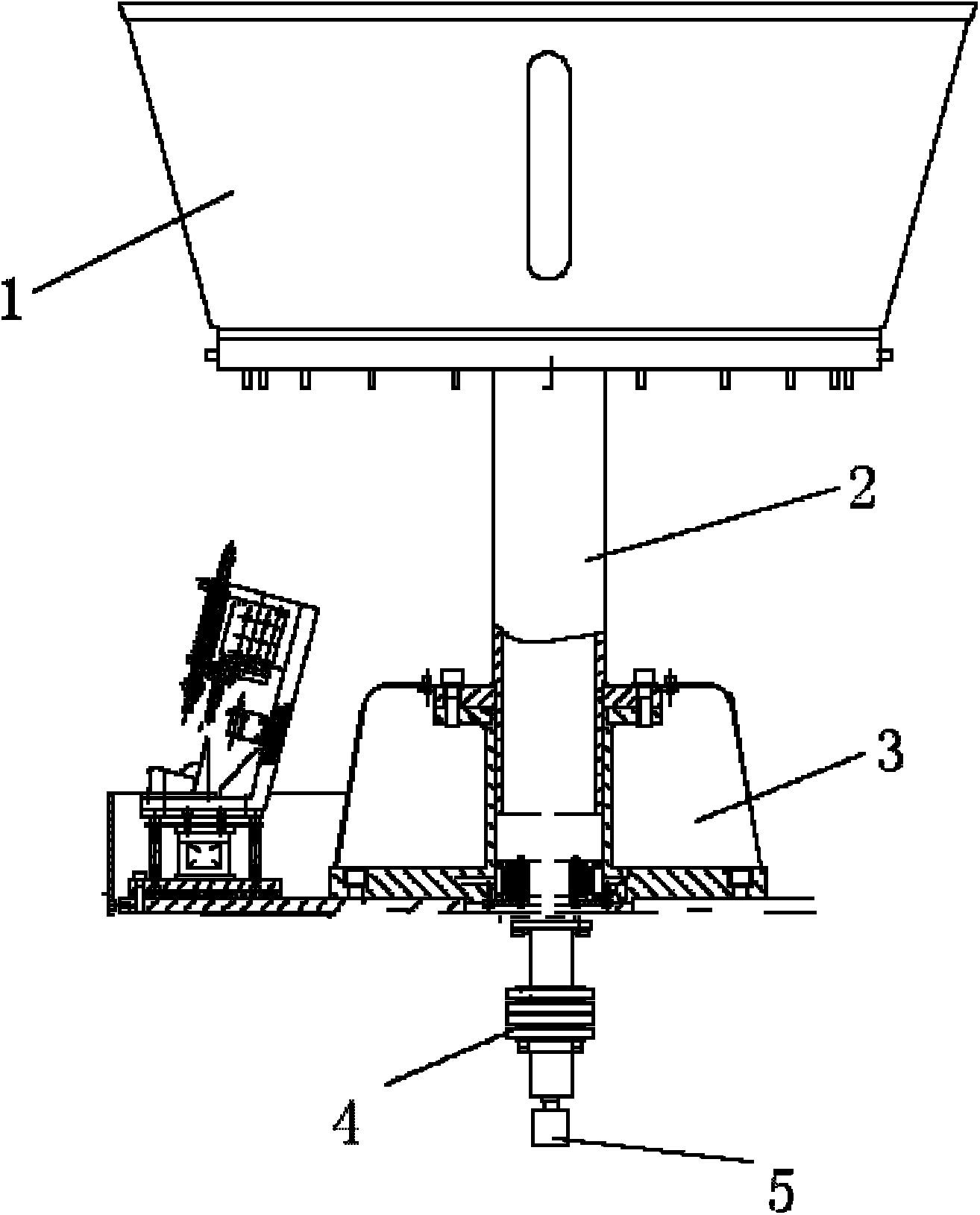

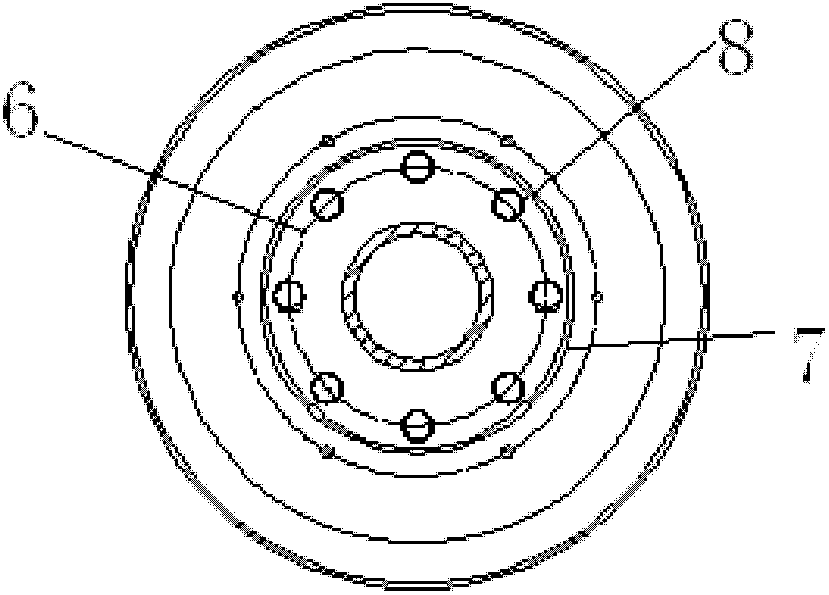

[0019] Such as figure 1 As shown, the present invention includes a sand filling bin body 1, a guide post 2, a main console 3, a collector slip ring 4, and a fixed shaft 5. The guide post 2 extends into the sand filling bin body 1, is fixedly connected with the sand filling bin body 1, and can rotate relative to the main operating table 3. Such as figure 2 As shown, the collector slip ring 4 is divided into two parts: the collector slip ring inner ring 6 and the collector slip ring outer ring 7. The collector slip ring inner ring 6 and the collector slip ring outer ring 7 are connected by an electromagnetic brush 8, and the collector slip ring Ring inner ring 6 and collector slip ring outer ring 7 can rotate relatively. The outer ring 7 of the collector slip ring is fixedly connected with the guide post 2, and the inner ring 6 of the collector slip ring is fixed on the main console 3 through the fixed shaft 5. The guide post 2 adopts a hollow structure, the power line penet...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap