A kind of auxiliary pipe cutting machine

A technology of pipe cutting machine and casing part, which is applied in the field of power-assisted pipe cutting machine, which can solve problems such as burden, low efficiency of pipe cutting, and great force exerted by the operator's arm, so as to improve work efficiency, reduce labor intensity, and ensure The effect of continuity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

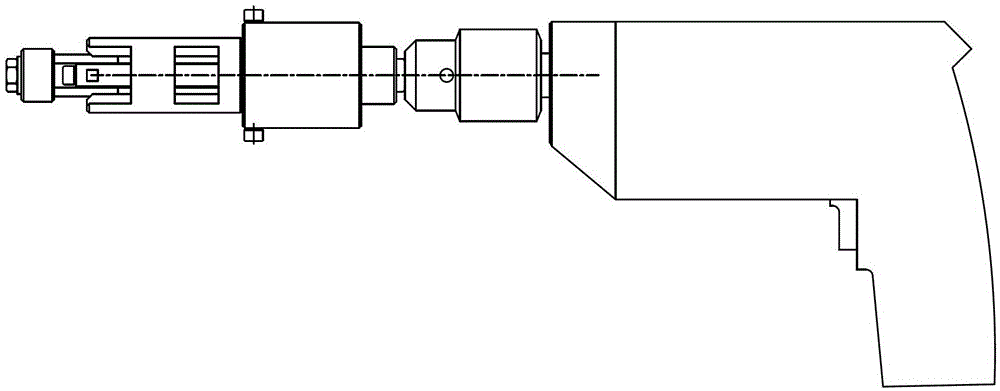

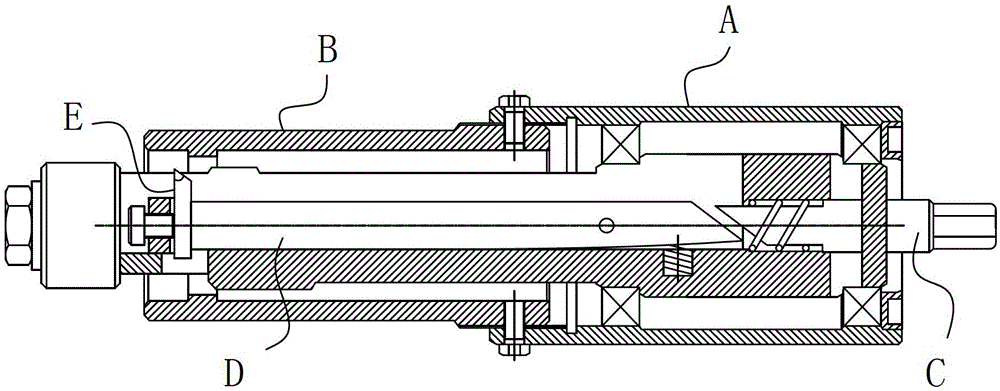

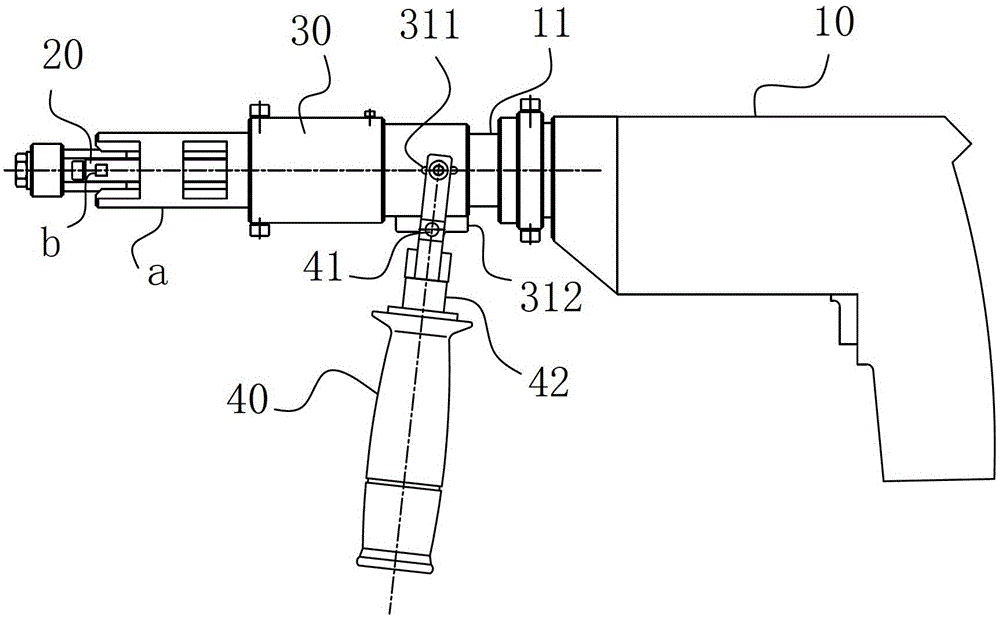

[0012] A power-assisted pipe cutting machine, comprising at least an axial displacement part composed of an electric drill 10 and a cutting main shaft 20 fixedly fitted with it, and a fixed part at least composed of a grip housing 30 sleeved outside the cutting main shaft 20, The fixed part is provided with a lever assembly 40 for pulling the axial displacement part for displacement. The hinge point 41 constituting the lever assembly 40 is arranged on the fixed part. A hinged fit relationship is formed between the displacement parts, and a gripping end for applying force and holding is arranged on the rod body 42; the distance between the hinge point 41 of the rod body 42 and the axial displacement part is smaller than the distance between the hinge point 41 and the hinge point 41 of the rod body 42. Its rod body 42 grips the distance between ends.

[0013] The present invention abandons the traditional backward manpower pressure structure with high labor intensity and low wor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com