Spiral demoulding device of bevel gear injection mold

A technology of injection mold and demoulding device, which is applied in the field of demoulding and ejection mechanism, can solve the problems of high production cost, high maintenance cost and complex structure of injection molds, and achieve the effects of low cost, simplified structure and reliable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

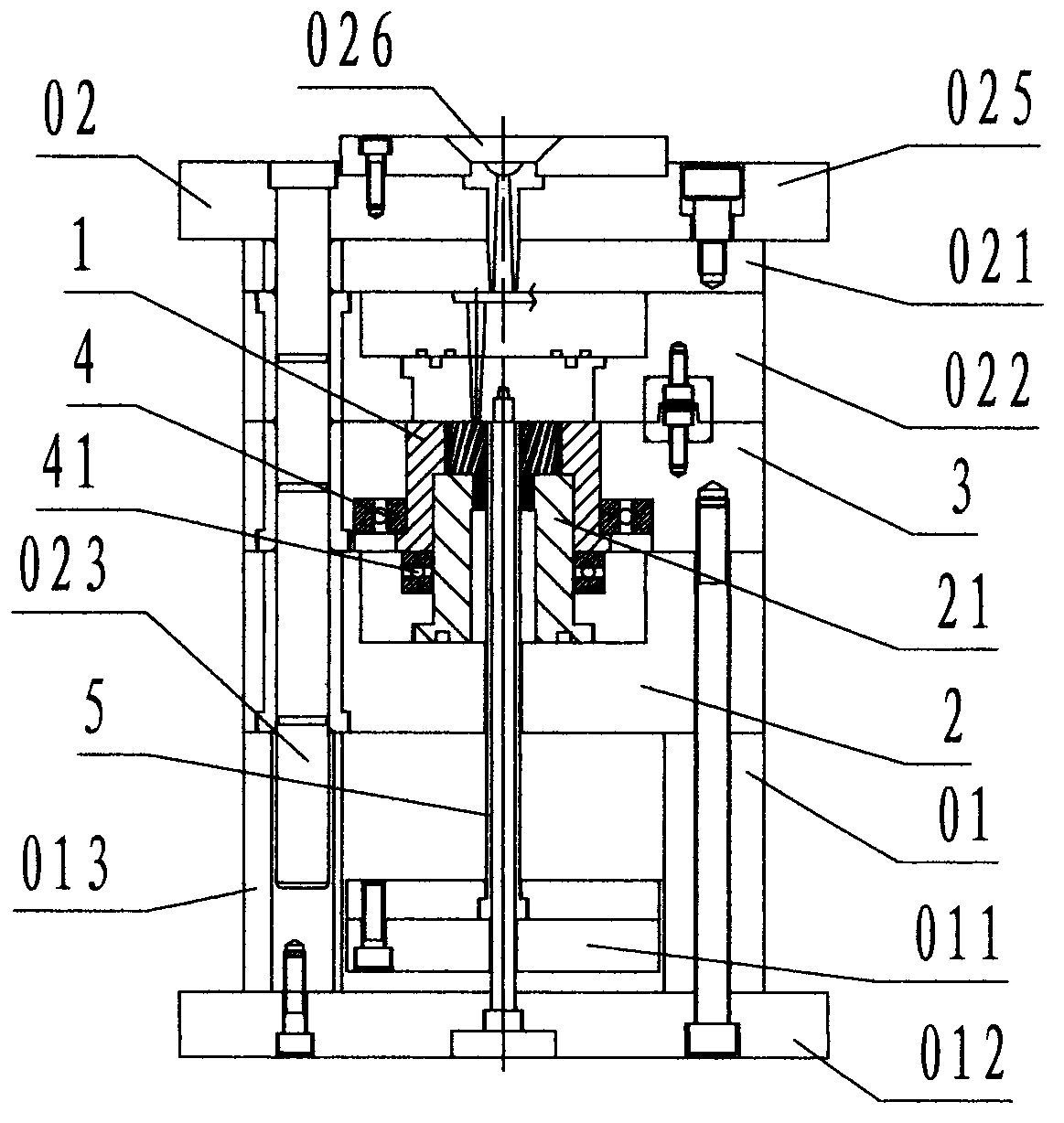

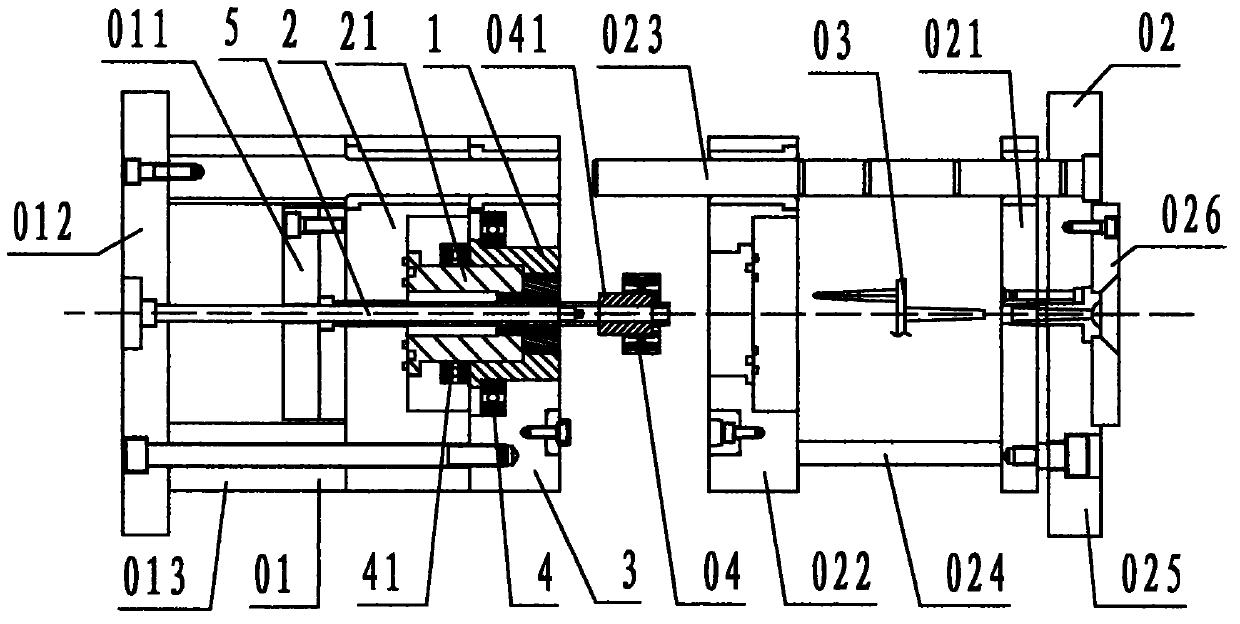

[0019] refer to Figure 1 ~ Figure 3 , a spiral demoulding device for a helical gear injection mold of the present invention, comprising a rotating cavity 1, a moving mold carrier plate 2, a pressing plate 3, an A bearing 4, a B bearing 41, and a sleeve 5, wherein: the rotating type Cavity 1 is a cylindrical step-shaped steel member with a flange on the bottom. The center of the rotary cavity 1 is provided with a circular stepped through hole with a small upper part and a larger lower part. The small stepped hole on the upper part of the rotary cavity 1 is called a helical tooth cavity. , the hole wall of the helical tooth cavity is provided with a profile for forming the cylindrical helical tooth of the helical gear product 04; the large stepped hole at the bottom of the rotary cavity 1 is called the bushing hole; the outer flange step of the rotary cavity 1 A bearing 4 is arranged on the upper surface, and the A bearing 4 is a radial ball bearing, and the inner ring of the A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com