Telescopic freight car

A telescopic, carriage technology, which is applied to the superstructure, vehicle parts, superstructure and other directions of a truck, can solve the problems of invariable carriage volume, inconvenient parking and occupation of parking spaces for carrying light-bubble goods, etc., and achieves low implementation cost, Simple structure and the effect of saving parking spaces

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

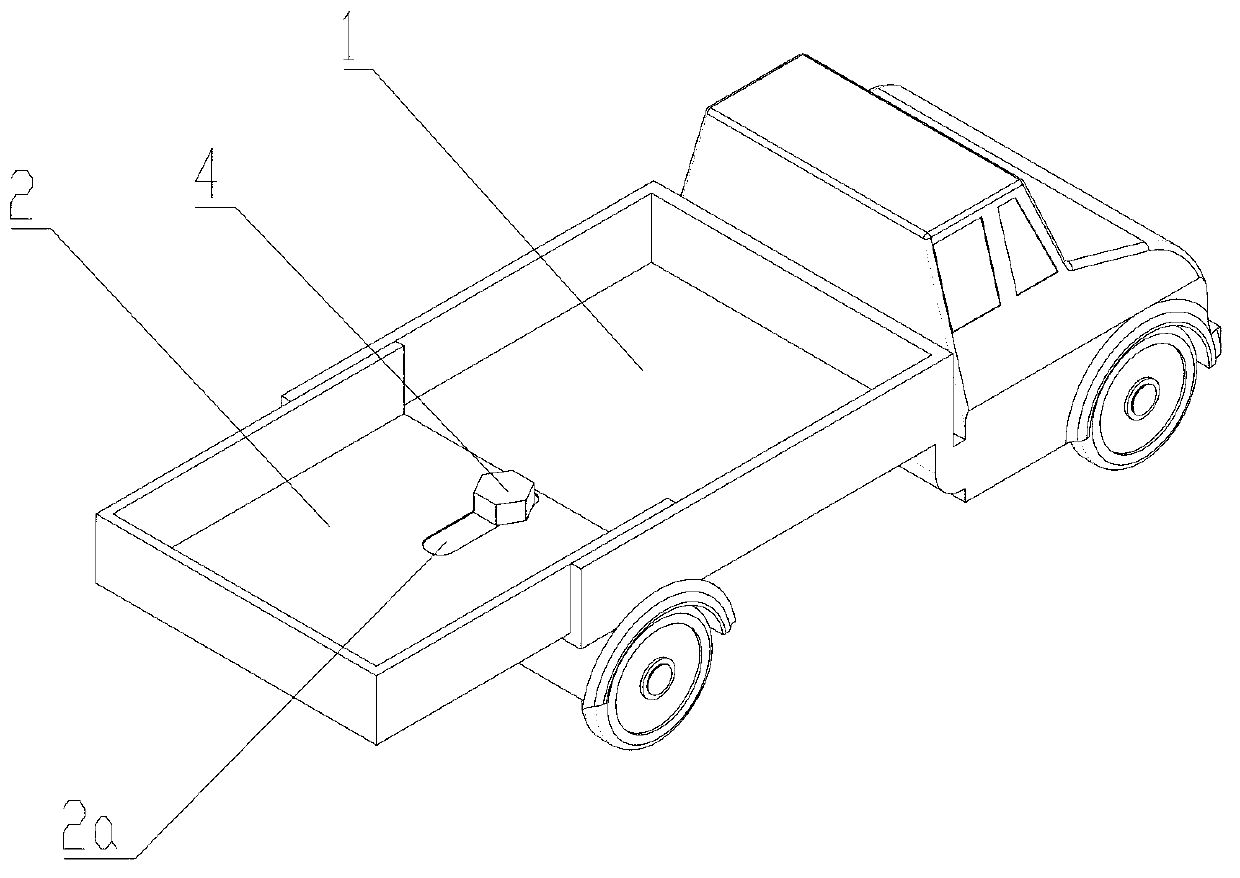

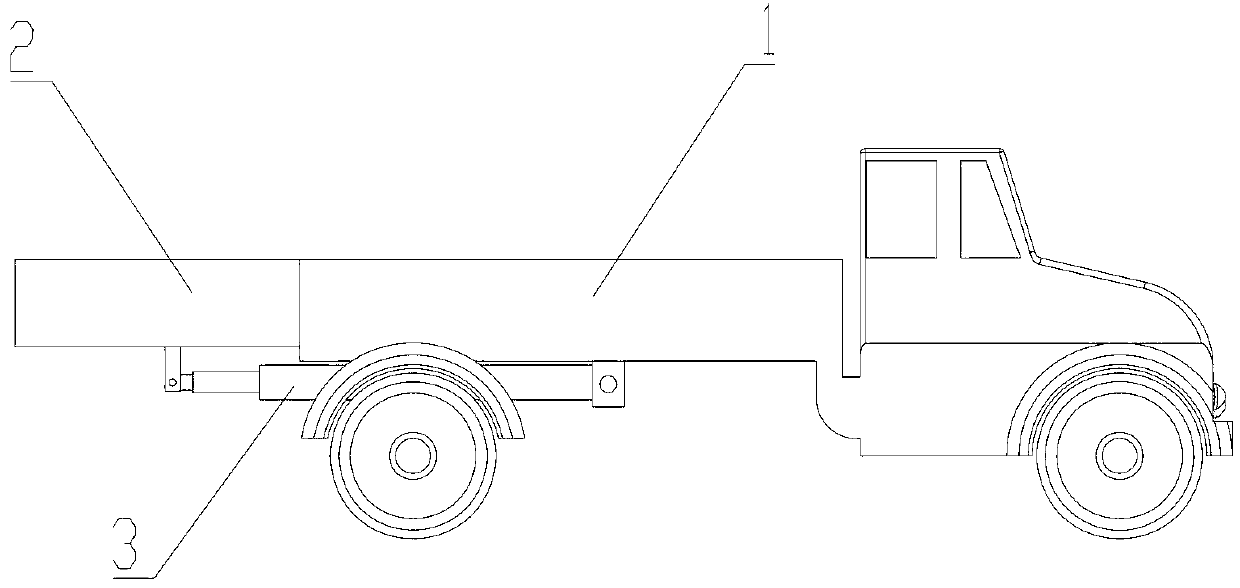

[0015] The present invention will be described in detail below in conjunction with the accompanying drawings, as shown in the figure: the retractable truck compartment of the present embodiment includes a fixed compartment 1, and is arranged on the fixed compartment 1 in a manner that can reciprocate longitudinally along the fixed compartment 1. Compartment 2, the telescopic drive device arranged on the fixed compartment 1 and the locking device for locking or loosening the fixed compartment 1 and the movable compartment 2, the longitudinal direction of the fixed compartment refers to the front and rear direction of the truck, and the telescopic drive device The motion output end is connected with the movable carriage 2, and is used to drive the movable carriage 2 to move backwards to extend or to move forward to shorten, so as to change the volume of the wagon and cargo compartment and adapt to different usage requirements.

[0016] As a further improvement of the above techni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com