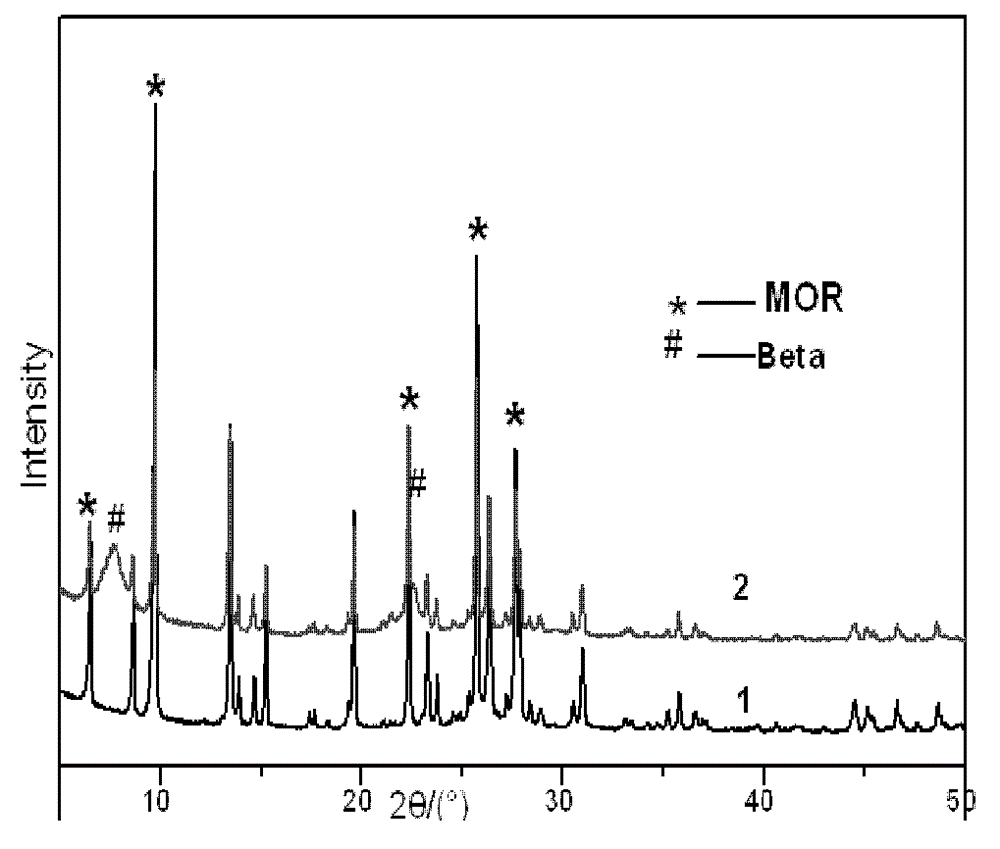

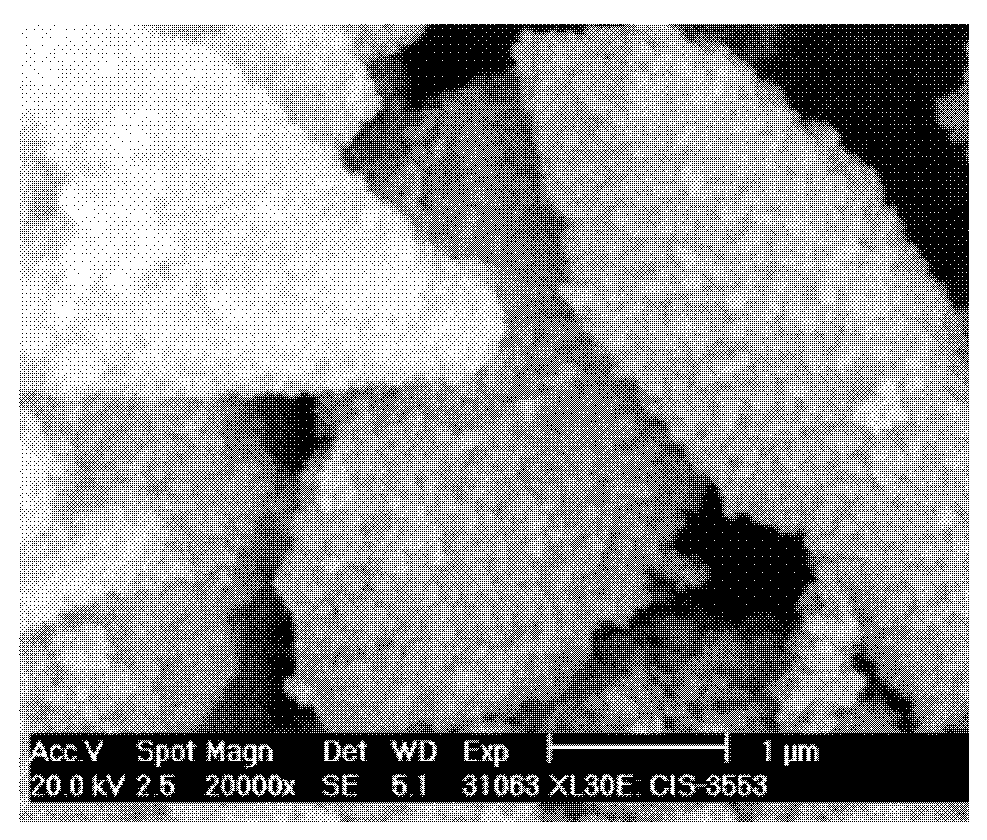

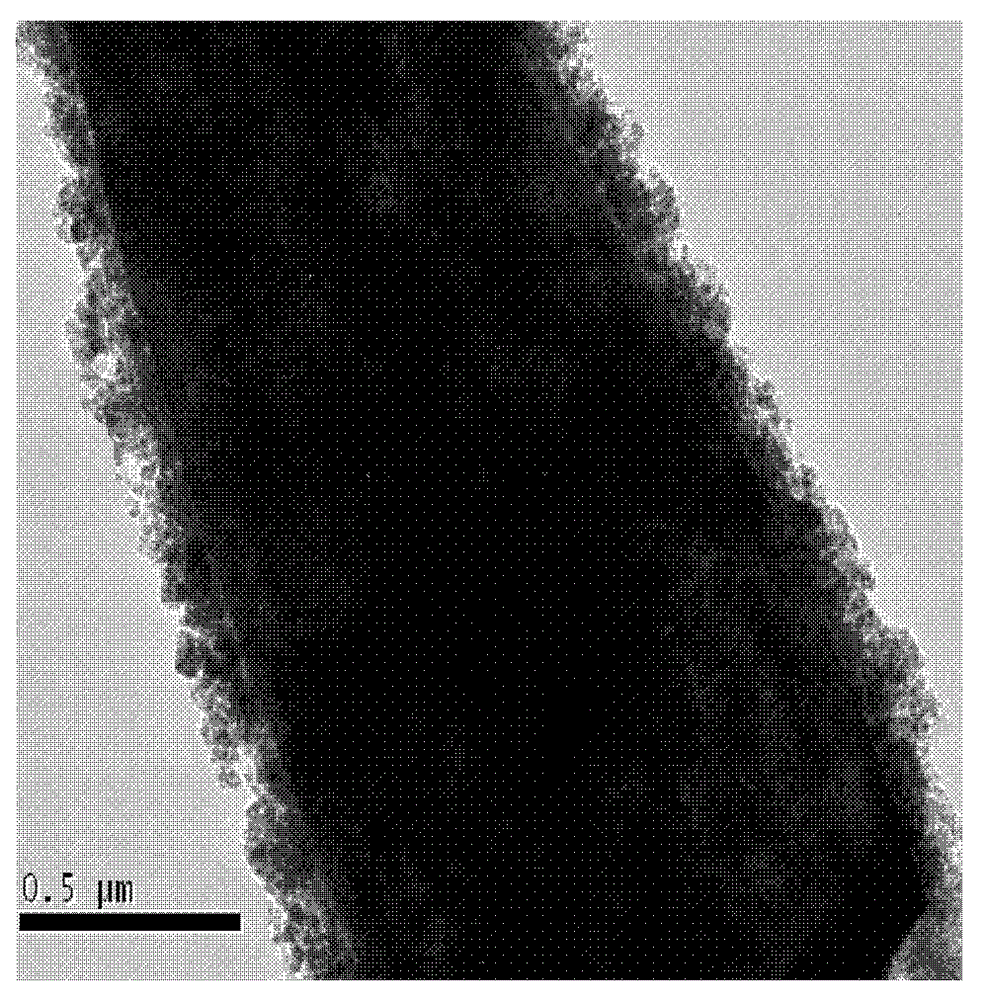

Synthesis method of MOR (Mordenite)-BEA (Beta Zeolite) core-shell zeolite

A core-shell molecular sieve and a synthesis method technology, applied in the direction of crystalline aluminosilicate zeolite, etc., can solve the problems of poor synthesis repeatability, low yield, weak force and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Concrete reactant proportioning and experimental method are as follows:

[0025] Ratio of reactants in nuclei seed: 7Na 2 O: 2.5NaF: 1 Al 2 o 3 : 30 SiO 2 : 360 H 2 o

[0026] The reactant ratio of β nanocrystal: 13(TEA) 2 O: 1Al 2 o 3 : 66SiO 2 : 780 H 2 o

[0027] Ratio of reactants for secondary growth of core-shell: 13(TEA) 2 O: 1 Al 2 o 3 : 71.4SiO2 2 : 2286H 2 o

[0028] Dissolve 112.5 grams of silica sol (40%wt) and 2.628 grams of NaF in 40 grams of deionized water to configure solution A; 4.1 grams of NaAlO 2 and 12.0 grams of NaOH were dissolved in 50 grams of deionized water to prepare Solution B. Slowly add solution B dropwise to solution A, stir well, and the resulting reaction mixture is crystallized at 170°C for 3 days to obtain large-grain nuclear phase MOR seed crystal I, the measured fluorine content is 614 μg / g, silicon The aluminum ratio was 20.4.

[0029] At 65°C, the MOR seed crystal I used as the nuclear phase was added to a 1% h...

Embodiment 2~6

[0036] Examples 2-6 are based on the synthesis ratio and synthesis conditions in Table 1 and Table 2, and are synthesized according to the method and steps similar to Example 1 to obtain core-shell molecular sieves CFS2-6#, see Table 2 for details.

[0037] Table 1

[0038]

[0039] Table 2

[0040]

Embodiment 7

[0042] Concrete reactant proportioning and experimental method are as follows:

[0043] Nucleus phase seed: industrial MOR (fluorine content 2 / Al 2 o 3 =22.6)

[0044] The reactant ratio of β nanocrystal: 13(TEA) 2 O: 1Al 2 o 3 : 66SiO 2 : 780 H 2 o

[0045] Ratio of reactants for secondary growth of core-shell: 13(TEA) 2 O: 1 Al 2 o 3 : 71.4SiO2 2 : 2286H 2 o

[0046] Dissolve 3 grams of PDDA (35%wt), 4.5 grams of ammonia solution (25%wt) in 142.5 grams of NaCl deionized aqueous solution (0.1mol / L) and stir evenly, and add 30 grams of industrial MOR as a nuclear phase molecular sieve to this surface modification Stir and keep at room temperature for 1 hour, filter and dry in air atmosphere at 60°C, add to zeolite beta nanocrystal suspension for pre-adhesion for 90 minutes, filter and dry in air atmosphere at 100°C The processed MOR powder is obtained. 4 grams of white carbon black, 0.765 grams of sodium aluminate, 14.137 grams of tetraethylammonium hydroxide s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com