Base cloth feeding and traversing device for tufting machine

A technology of traversing device and tufting machine, which is applied in the field of tufting machine base fabric feeding and traversing device, can solve the problems that the base fabric cannot be moved laterally, and achieve good running performance, cost saving and wide applicability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

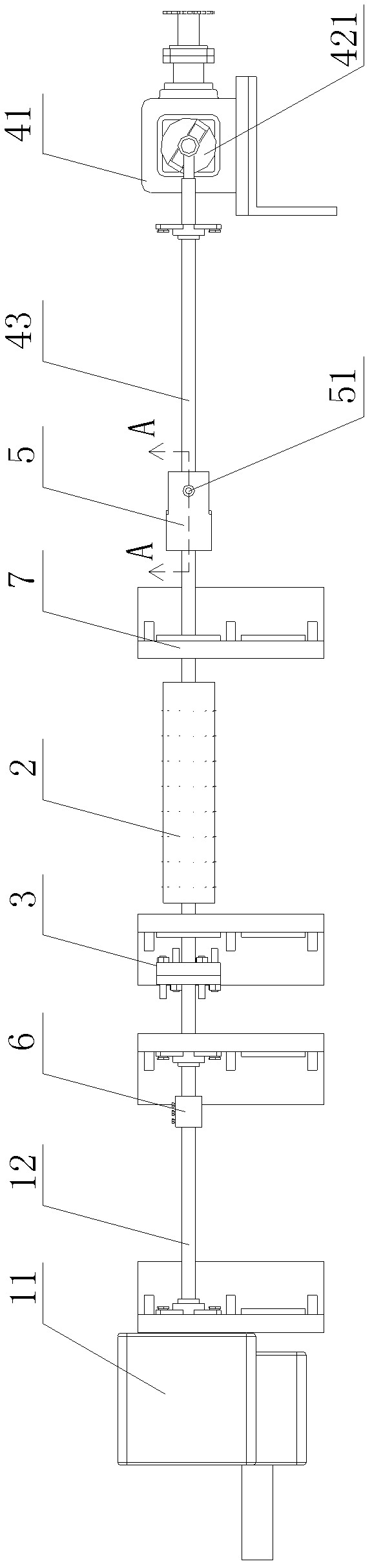

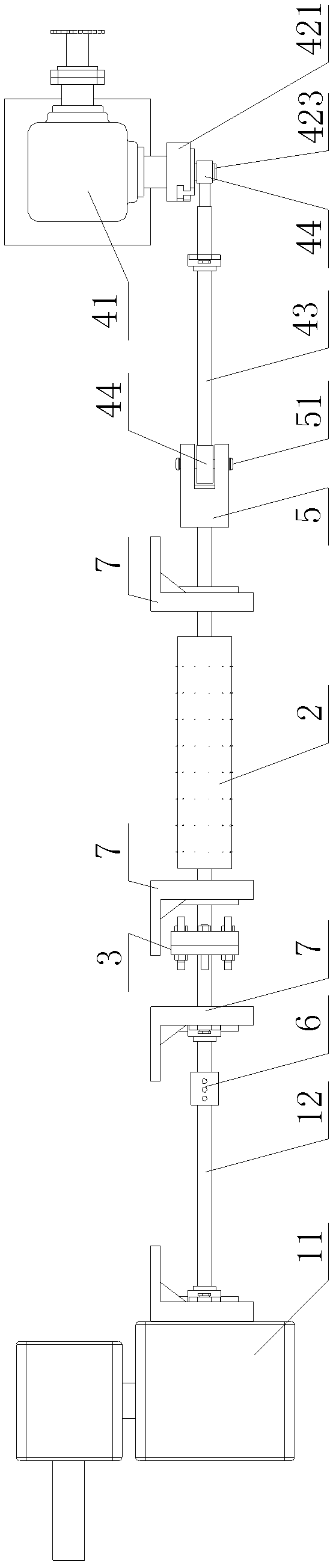

[0029] See figure 1 , the present invention has turning mechanism 1 and licker-in roller 2; Turning mechanism 1 has left reduction box 11 and rotating shaft 12; Turning shaft 12 has two, is connected by shaft coupling 6 between turning shaft 12; The reduction box 11 is connected to the licker-in roller 2 at the other end, and the rotating mechanism 1 drives the licker-in roller 2 to rotate at a constant speed through the rotating shaft 12 .

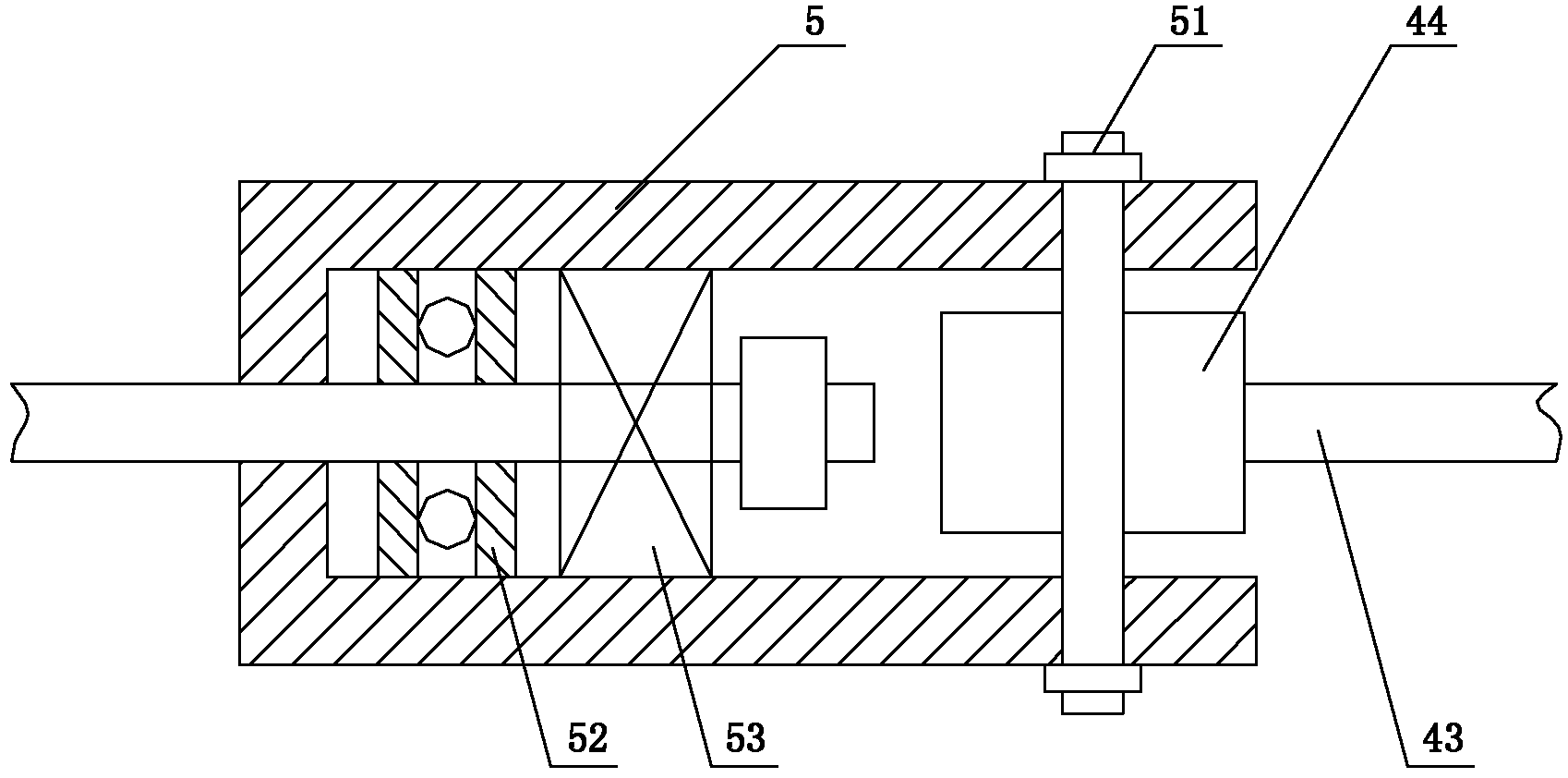

[0030] There is also a sliding connection assembly 3 and an adjustable traverse mechanism 4; the sliding connection assembly 3 is arranged between the rotating shaft 12 and the licker-in roller 2; the sliding connecting assembly 3 has a rotating shaft connecting flange 31 and a licker-in roller connecting flange 32 , the rotating shaft connection flange 31 is fixedly connected with the rotating shaft 12, the licker-in roller connecting flange 32 is fixedly connected with the licker-in roller 2, the rotating shaft connecting flange 31 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com