Mine tunnel compressed air sequent conveying device and conveying method thereof

A technology of compressed air and conveying equipment, which is applied in mining equipment, valve equipment, mining equipment, etc., and can solve problems such as inability to ensure the normal operation of pneumatic machinery, large strokes, and non-constant pressure of air storage tanks, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The high-pressure gas source supply mode of existing coal mine underground pneumatic devices mostly uses movable gas storage tanks or very long gas pipes as the gas source. The structure of these gas supply facilities is very inconvenient. However, the long-distance return and release of the trachea is also very inconvenient and safe, and the work efficiency is low and the labor intensity of the workers is very high.

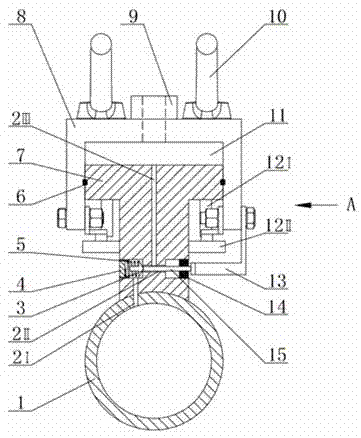

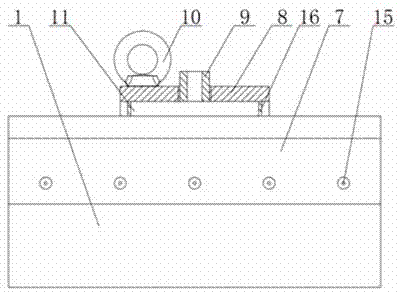

[0026] The present invention aims at the deficiencies existing in the existing gas supply facility structure under the coal mine, and proposes a mine roadway compressed air continuous conveying device, which realizes the continuous supply of high-pressure gas like an electric slide wire, without the need for gas tanks or very long gas pipelines The gas supply is very convenient and fast, and the work efficiency is improved. The specific technical scheme is as follows:

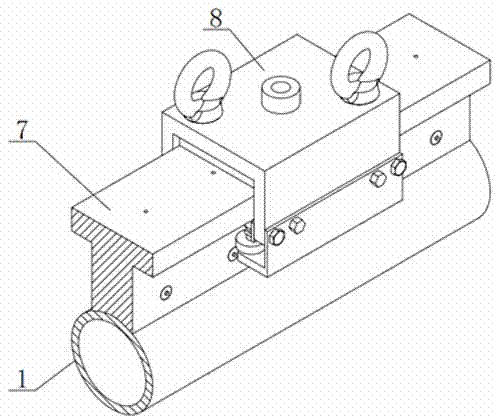

[0027] A mine roadway compressed air continuous conveying device, including compressed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com