Elastic clamping ring

A technology of elastic snap rings and snap rings, which is applied in the direction of connecting components, friction-clamped detachable fasteners, mechanical equipment, etc. Does not have other problems, to achieve the effects of not being prone to fatigue failure, improving elasticity, and good blocking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

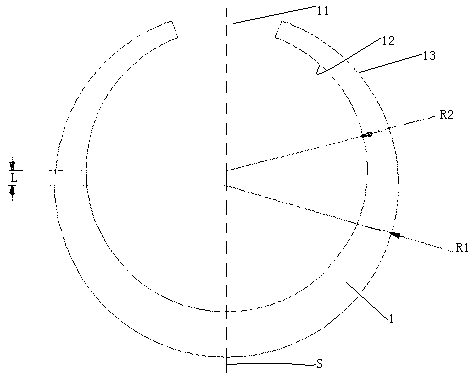

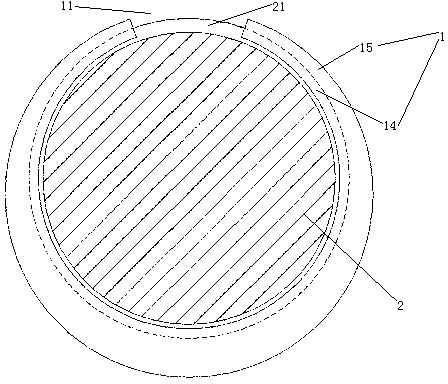

[0032] Embodiment one, see figure 1, an elastic snap ring, comprising an elastic snap ring body 1 . The clasp body 1 is provided with an opening 11 . The inner peripheral surface 12 of the clasp body is a rotating surface, and the rotating surface is a cylindrical surface. The outer peripheral surface 13 of the clasp body is a rotating surface, and the rotating surface is a cylindrical surface. The axis of the rotating body where the outer peripheral surface 13 of the snap ring body is located is parallel to the axis of the rotating body where the inner peripheral surface 12 of the snap ring body is located. The axis of the rotating body where the outer peripheral surface 13 of the snap ring body is located is located on the lower side of the axis of the rotating body where the inner peripheral surface 12 of the snap ring body is located. The opening 11 is located on the upper side of the axis of the rotating body where the inner peripheral surface 12 of the clasp body is l...

Embodiment 2

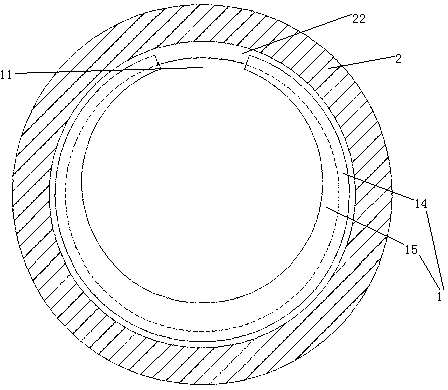

[0035] Embodiment two, see Figure 4 , the difference from the first embodiment is that: the axial end surface of the clasp body 1 is provided with a mounting groove 16 . The installation slot 16 is located on the blocking portion 15 . The mounting groove 16 is in the shape of an arc extending along the circumferential direction of the clasp body 1 . The mounting groove 16 extends to two sides of a plane S that equally divides the snap ring body along the circumferential direction. A reinforcement block 3 is provided in the installation groove 16 . The reinforcing block 3 is arc-shaped. It is a tight fit between the reinforcement block 3 and the installation groove 16 . Four booster hooks 31 are arranged on the axially outer end surface of the reinforcement block 3 . The distance between the axis of the rotating body where the outer peripheral surface of the snap ring body is located and the axis of the rotating body where the inner peripheral surface of the snap ring bod...

Embodiment 3

[0038] Embodiment three, see Image 6 , the difference from the second embodiment is: the right end of the installation groove 16 extends to the clamping portion 14 . Between the reinforcing block 3 and the mounting groove 16 is clearance fit, that is, the reinforcing block 3 is stuck in the mounting groove 16 and slides freely.

[0039] The method for installing and installing the present invention is:

[0040] see Image 6 , so that the snap ring body 1 is separated from the reinforcement block 3, first install the snap ring body 1 into the outer slot 21 of the object 2 provided with the slot, and then assemble the reinforcement block 3 into the installation slot 16 at the stopper 15 in the above part;

[0041] see Figure 7 , and then make the reinforcement block 3 slide toward the right end of the installation groove in the installation groove 16, so that the right end of the reinforcement block 3 enters the part of the installation groove 16 located on the clamping pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com