Pipe joint locking device

A technology for locking devices and pipe joints, which is applied in the direction of pipes/pipe joints/fittings, sealing surface connections, passing components, etc., and can solve unfavorable pipe joint connection and disassembly, crowded positions between pipe joints, loose pipe joints, and eccentricity and other problems, to achieve good fastening effect, improve strength, and prevent slack

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in detail below in conjunction with the accompanying drawings.

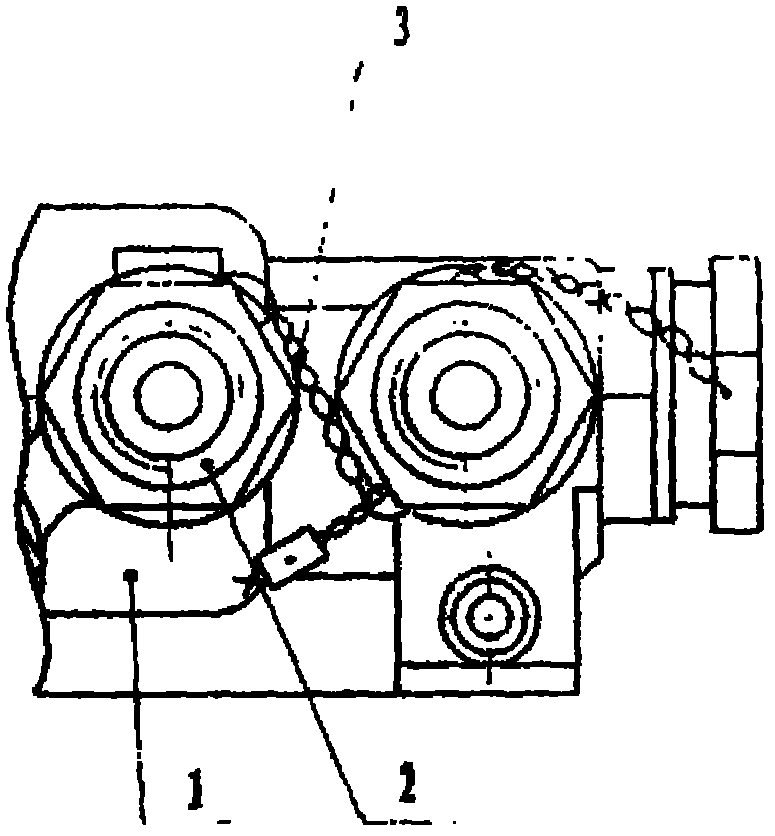

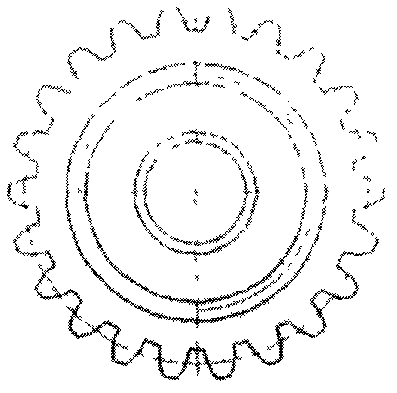

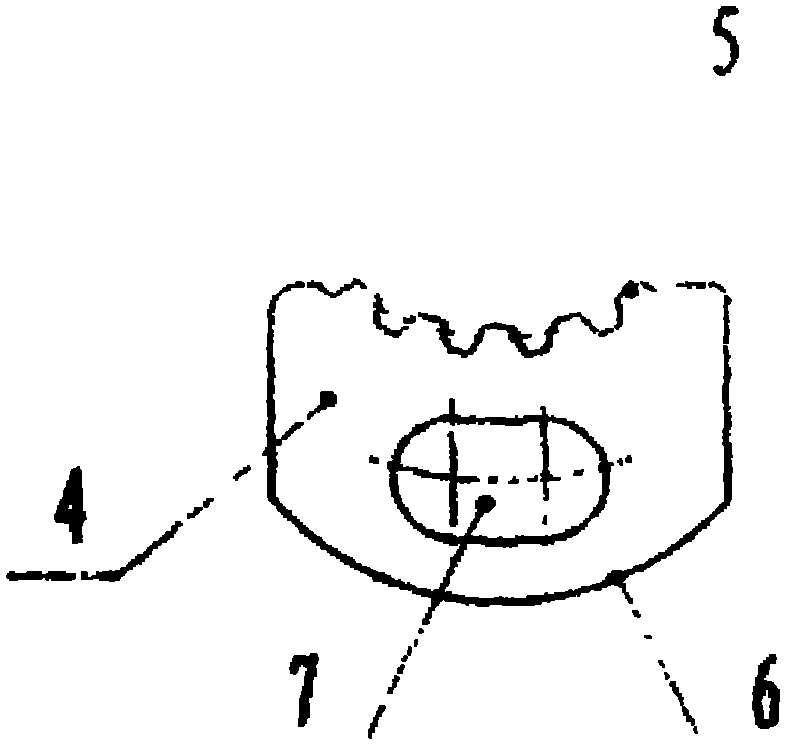

[0014] Figure 4 It is a structural schematic diagram of the pipe joint locking device of the present invention used in a certain engine accessory. In this embodiment, the pipe joint 2 with external splines is an improved version of the existing pipe joint of the accessory. The hexagonal part of the cylinder is changed into a cylinder with a certain thickness, and an external spline is formed on the outer edge of the cylinder with an involute tooth profile, and the other parts remain unchanged; the material used for the lock 4 is the same as that of the pipe joint, and the shape is a fan-shaped structure , the inner end surface 5 is a spline tooth groove structure, the number of teeth meshing with the outer spline is 4, the outer end surface 6 is arc-shaped, the arc diameter is Φ13mm, the total length of the lock 4 is 15mm, and it is in the middle of the lock sector ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com