Non-contact temperature measuring method

A technology of temperature measurement and brightness, applied in the field of non-contact temperature measurement, it can solve the problems of small temperature range, unusable, poor practicability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

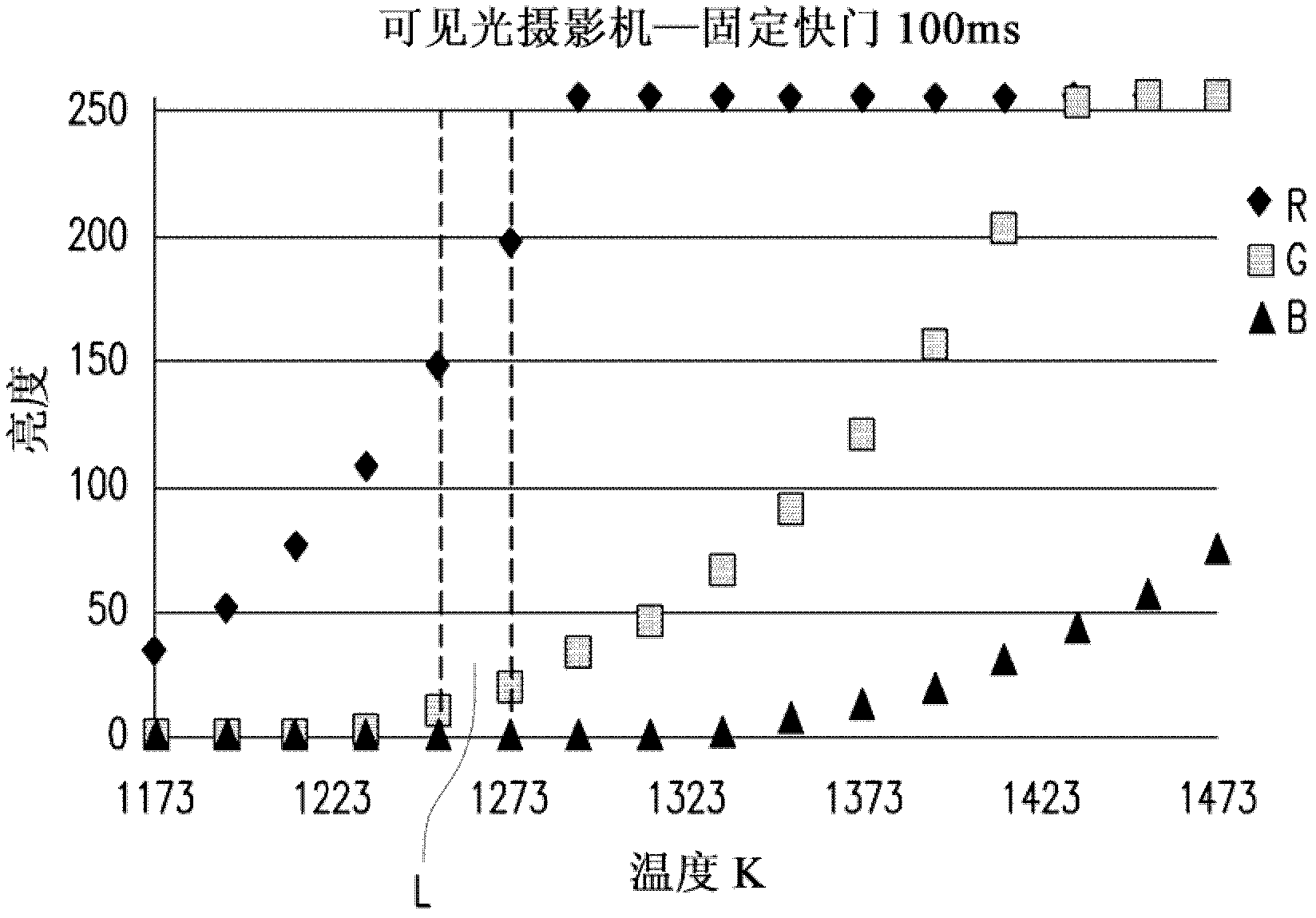

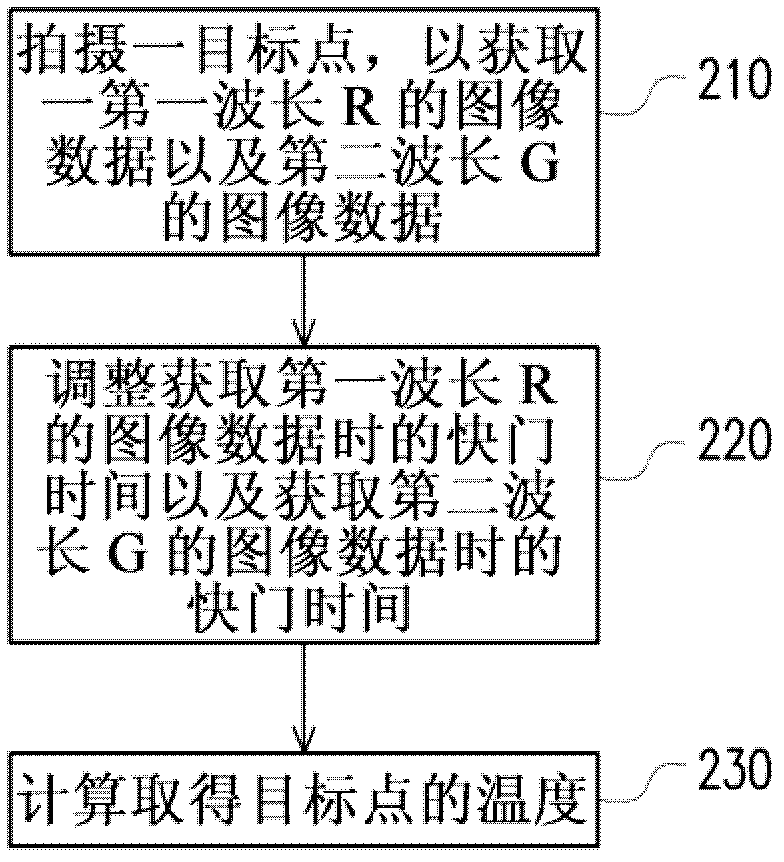

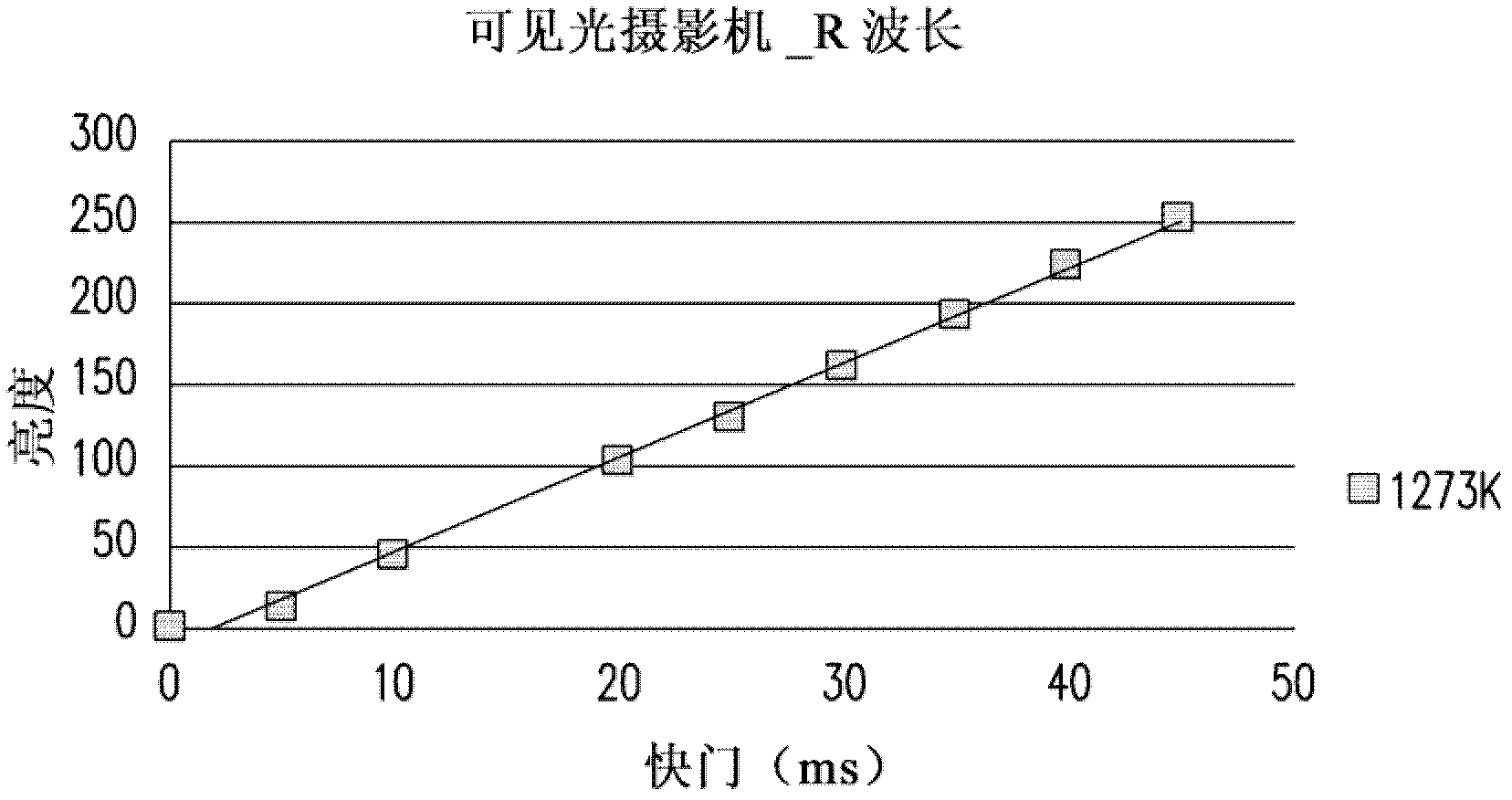

[0026] figure 2 It is a flowchart of a temperature measurement method according to an embodiment of the present invention. In this embodiment, the main process includes a step 210 of photographing a target point to obtain image data of a first wavelength R and image data of a second wavelength G. When shooting the target point, step 220 is also executed to adjust the shutter time when acquiring the image data of the first wavelength R and the shutter time when acquiring the image data of the second wavelength G, so as to obtain a first wavelength R corresponding to A brightness and a second brightness corresponding to the second wavelength G. Finally, in step 230 , the temperature of the target point is obtained through calculation.

[0027] In an embodiment of the present invention, the step of adjusting the shutter time when acquiring the image data of the first wavelength R and the shutter time when acquiring the image data of the second wavelength G is carried out by i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com