Method for analyzing abrading metal particles in lubricating oil

A technology of metal particles and analysis methods, applied in the direction of analysis materials, instruments, etc., can solve the problems such as the inability to determine the specific material grade of the wear metal particles in the lubricating oil, the lack of published materials and patents, and the inability to achieve accurate positioning.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

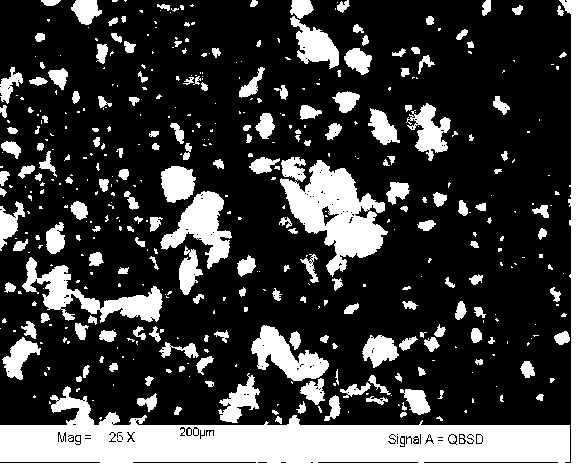

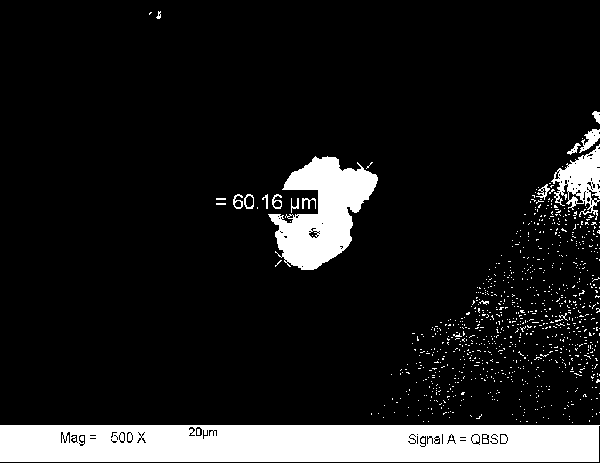

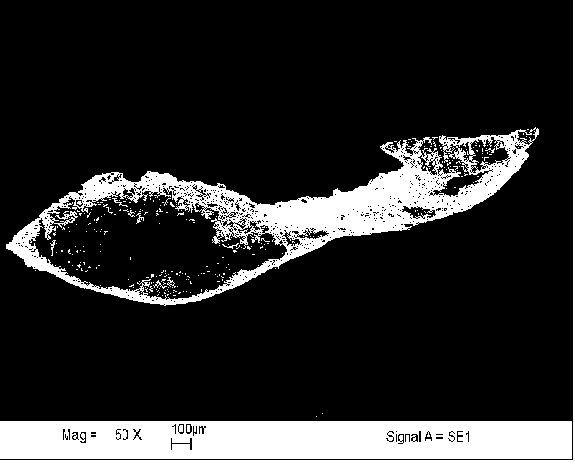

[0024] This embodiment provides an analysis method for wear metal particles in lubricating oil, which is characterized in that: in the analysis method for wear metal particles in lubricating oil, since the wear metal particles in the transmission lubrication system exist in lubricating oil, these The metal particles are extracted and prepared into a sample suitable for analysis, and then the sample is quantitatively analyzed by an appropriate method to finally determine the specific material of the worn metal particles;

[0025] (1) Extraction of worn metal particles

[0026] Extraction of wear metal particles smaller than 250μm: Due to the small size of this type of wear metal particles, they cannot be observed with the naked eye, and cannot be directly extracted by conventional means. At the same time, it is also necessary to ensure that there is no accumulation of wear particles after extraction, and their morphology cannot be damaged , using the ferrography analysis techno...

Embodiment 2

[0035] This embodiment provides an analysis method for wear metal particles in lubricating oil, which is characterized in that: in the analysis method for wear metal particles in lubricating oil, since the wear metal particles in the transmission lubrication system exist in lubricating oil, these The metal particles are extracted and prepared into a sample suitable for analysis, and then the sample is quantitatively analyzed by an appropriate method to finally determine the specific material of the worn metal particles;

[0036] (1) Extraction of worn metal particles

[0037] Extraction of wear metal particles smaller than 250μm: Due to the small size of this type of wear metal particles, they cannot be observed with the naked eye, and cannot be directly extracted by conventional means. At the same time, it is also necessary to ensure that there is no accumulation of wear particles after extraction, and their morphology cannot be damaged , using the ferrography analysis techno...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com