Centrifugal pump

A technology for centrifugal pumps and pump shafts, applied to pumps, drive pumps, non-variable pumps, etc., can solve problems such as complex structures and pump stability, and achieve reduced slurry loss and no slurry loss Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

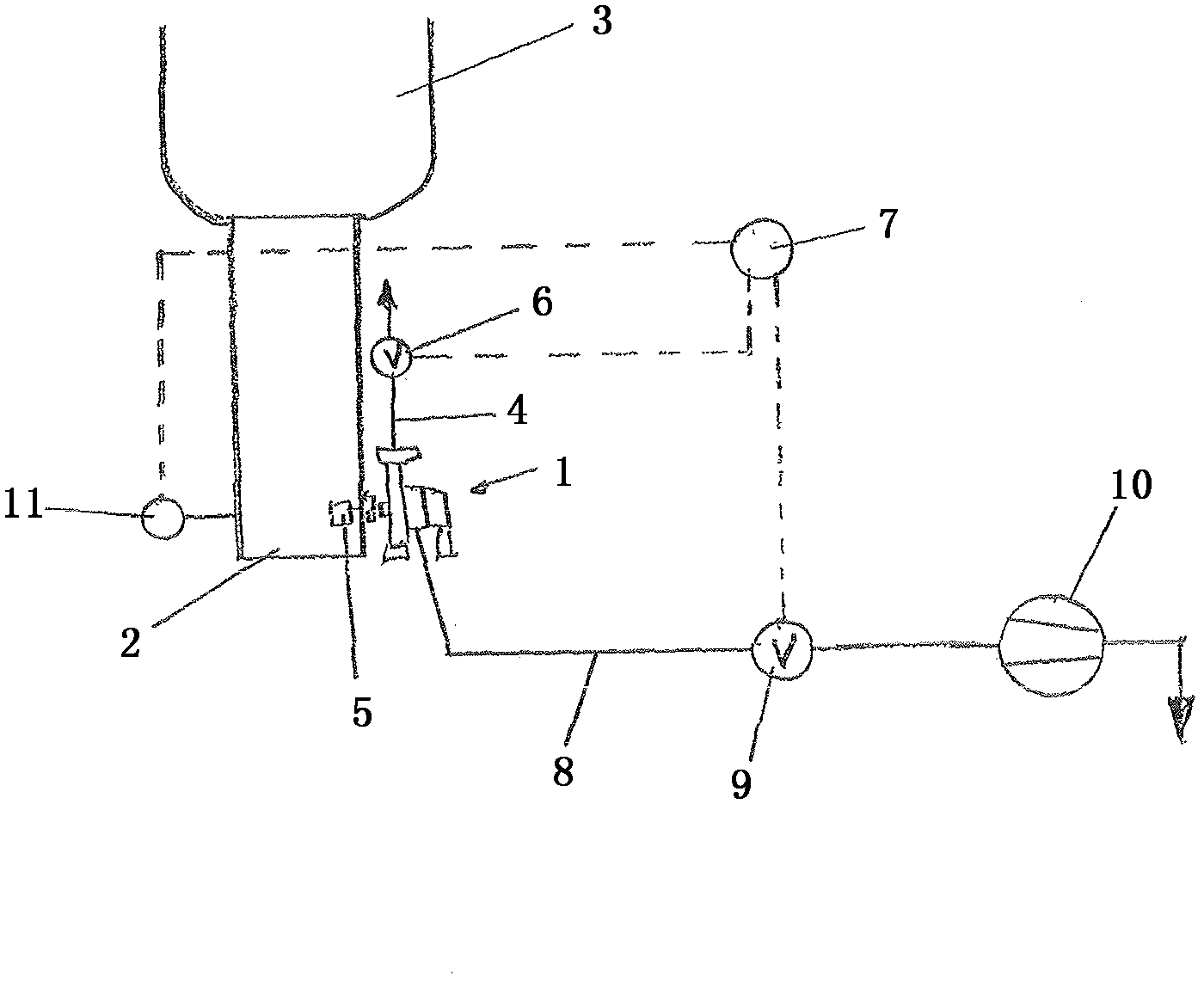

[0013] figure 1 Shown is a system for conveying a gas-containing suspension with a prior art degassing device. Here, the centrifugal pump 1 is installed in a lower side portion of a standpipe 2 arranged below a large liquid storage tank 3 such as a bleaching tower or the like. The pump 1 has a discharge pipe 4 for the medium to be pumped, for example a fiber stock suspension, and at the inlet there is a rotor 5 which is located integrally inside the standpipe 2 and is integrated with the wall of the standpipe 2 in the The combined rotor 5 is intended to generate turbulent flow for fluidizing the fiber stock suspension. In the outlet pipe 4 there is a regulating valve 6 which is connected to a control unit 7 .

[0014] Furthermore, the pump 1 has an exhaust pipe 8 in which a regulating valve 9 and a vacuum pump 10 are installed. The control unit 7 controls the fluid in the outlet pipe 4 by means of the control valve 6 and in particular by means of the control valve 9 in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com