Automatic label printing method for riveting machine

An automatic printing and riveting machine technology, applied in the field of mechanical processing, can solve the problems of artificial inability to control the riveting process, complex riveting machine system, high error rate, and achieve the effect of convenient classification, delivery efficiency, and management efficiency improvement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in detail below in conjunction with various embodiments shown in the accompanying drawings. However, these embodiments do not limit the present invention, and any structural, method, or functional changes made by those skilled in the art according to these embodiments are included in the protection scope of the present invention.

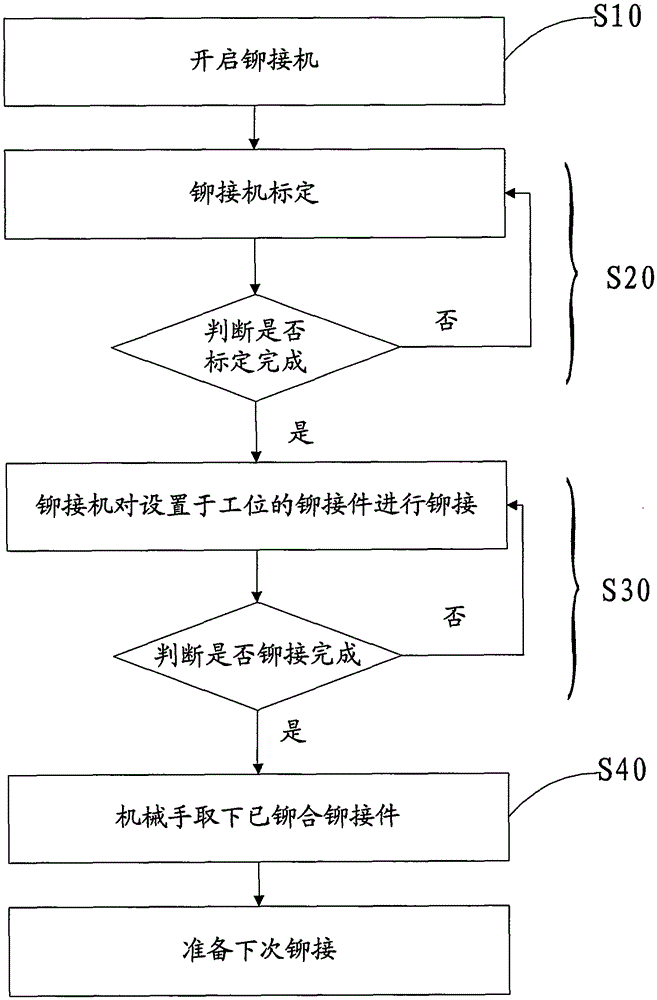

[0026] ginseng figure 1 As shown, the riveting machine provided by the present invention specifically includes the following steps to perform the riveting work:

[0027] S10: Turn on the riveting machine;

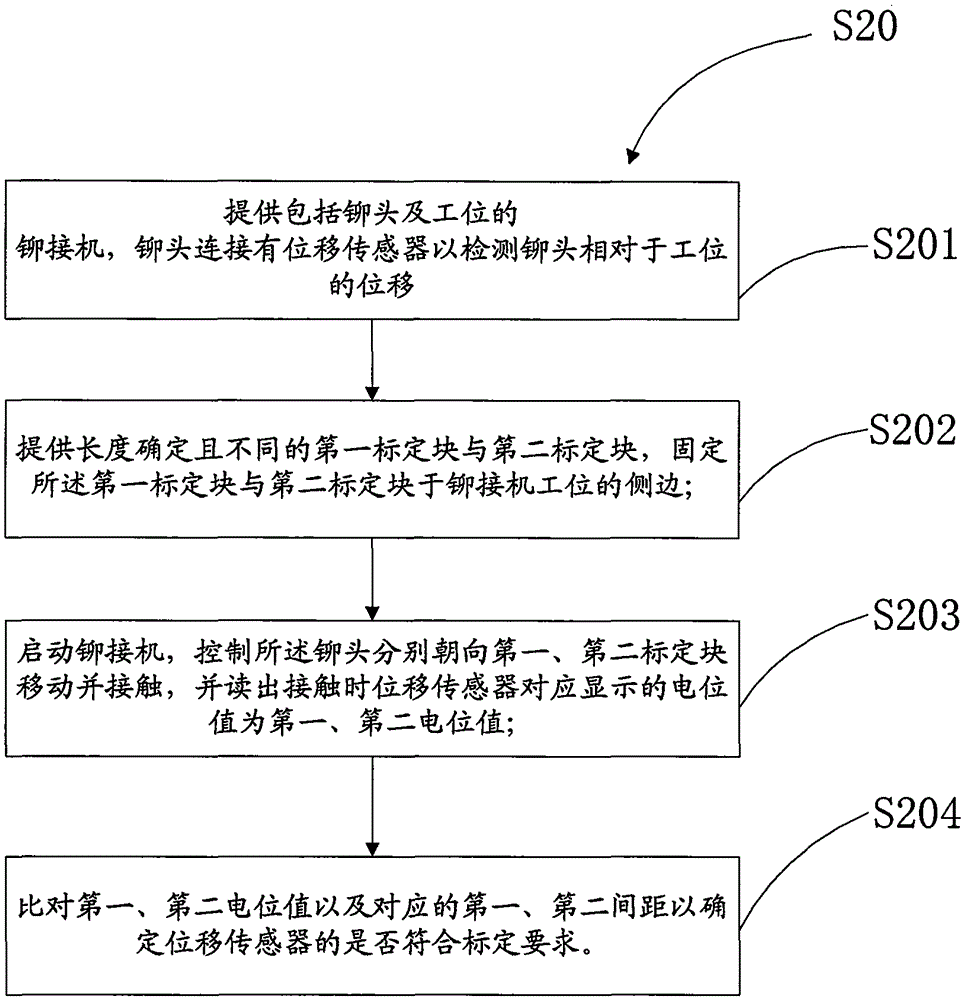

[0028] S20: Calibrate the riveting machine, judge whether the calibration is completed, if yes, perform step S30; if not, re-execute step S20;

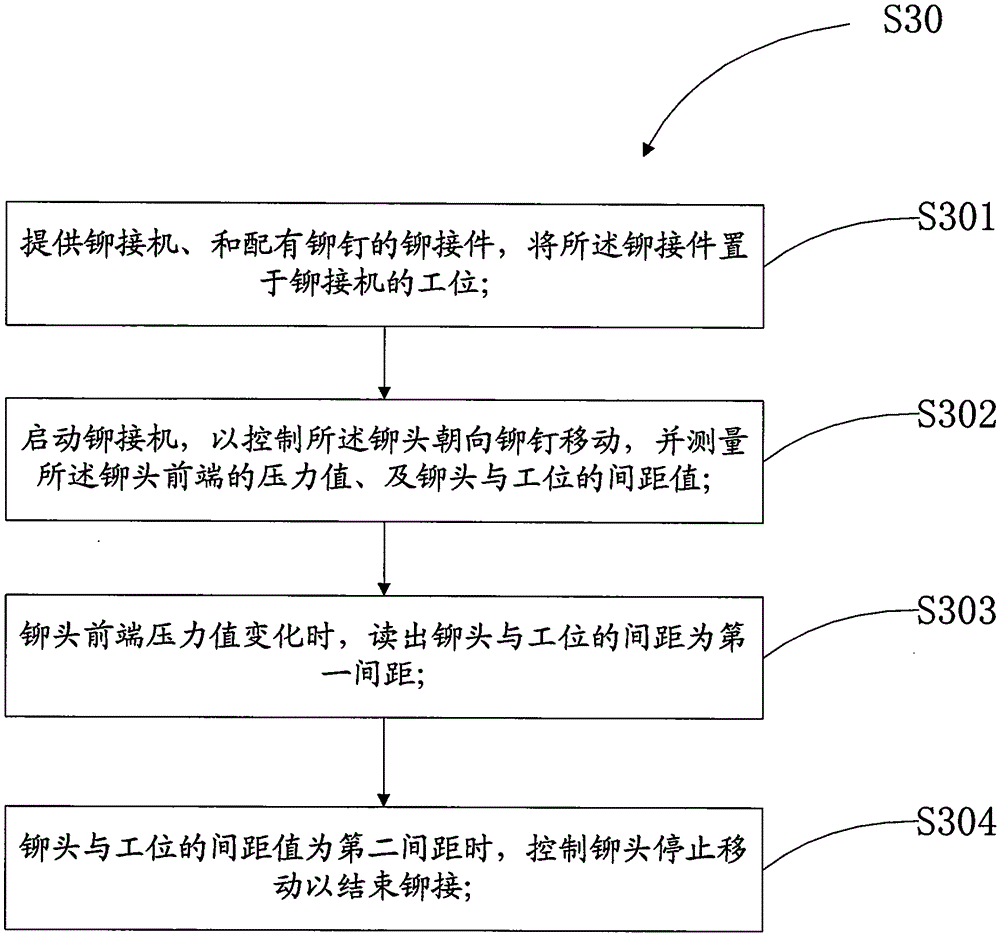

[0029] S30: Control the riveting head of the riveting machine to perform riveting on the riveting piece set at the station, and judge whether the riveting is completed, if yes, perform step S40; if not, re-execute step S30;

[0030] S40: Control the manip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com