Portable electric welding machine

An electric welding machine, portable technology, applied in arc welding equipment, welding equipment, manufacturing tools, etc., can solve the problems of long distance between electric welding machine and electric welding position, high safety factor, threat to personal safety, etc., to prevent danger and stabilize output. The effect of high current and safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

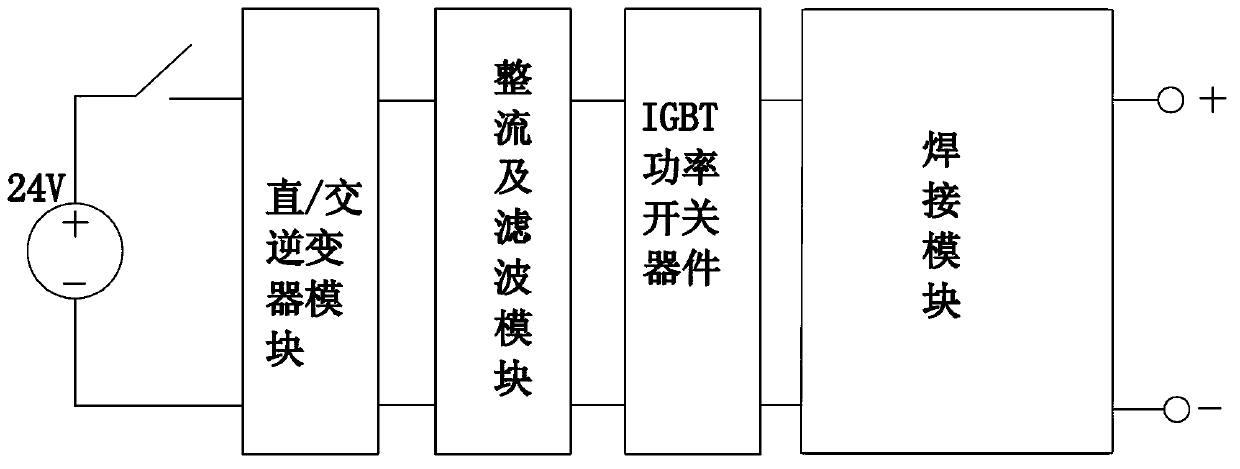

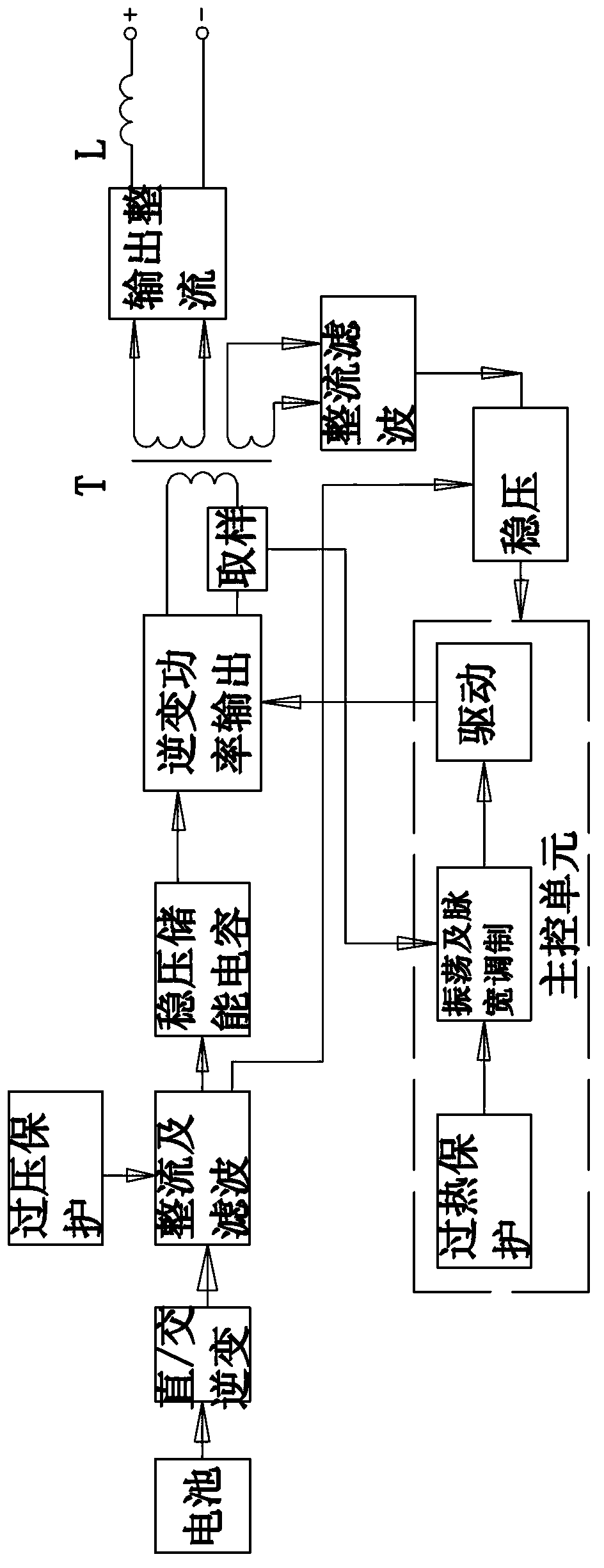

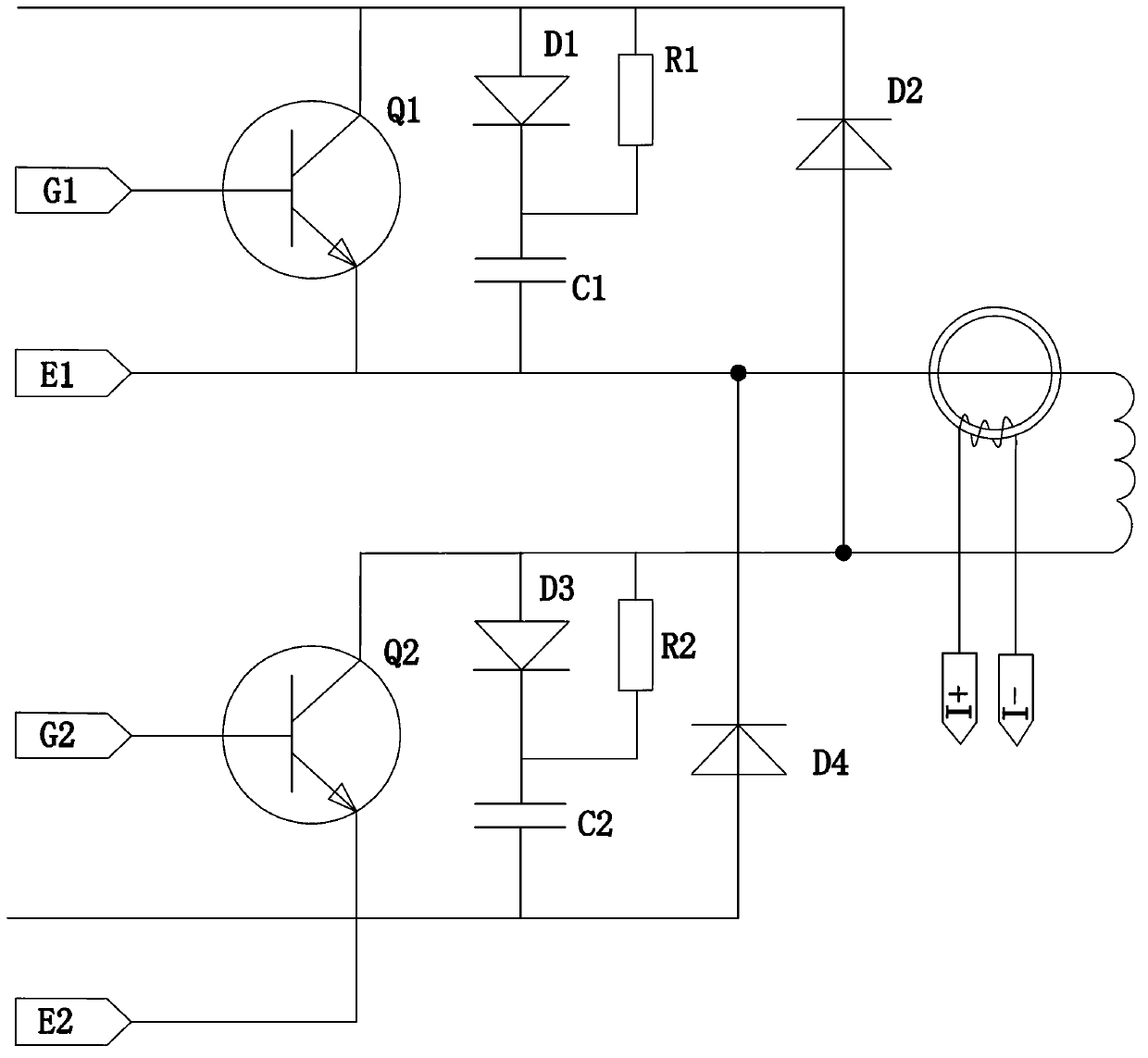

[0028] Embodiment: a kind of portable electric welding machine (see attached figure 1 ), including the shell, which is equipped with a battery pack composed of two sets of four 12V / 24AH lead-acid revolving batteries connected in series. Then connect the rectification and filtering module, the rectification and filtering module is connected to the IGBT power switching device for frequency modulation, and the IGBT power switching device is connected to the welding module. The welding module includes inverter power output circuit, transformer, output rectification circuit and main control unit (see attached figure 2). The inverter power output circuit is connected to the transformer, the transformer is connected to the output rectifier circuit, the inverter power output circuit is connected to the main control unit, the primary winding of the transformer is connected to the sampling circuit, and the sampling circuit is connected to the main control unit. The main control unit ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com