Hand power tool having a drum-type tool change magazine

A hand-held machine tool and tool replacement technology, which is applied in the direction of tool changing devices, manufacturing tools, motor tools, etc., can solve the problems of hand-held machine tools such as injury, comfort damage, and tool drop-off, so as to reduce the risk of injury and reduce the cost. The effect of blocking parts and solid operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

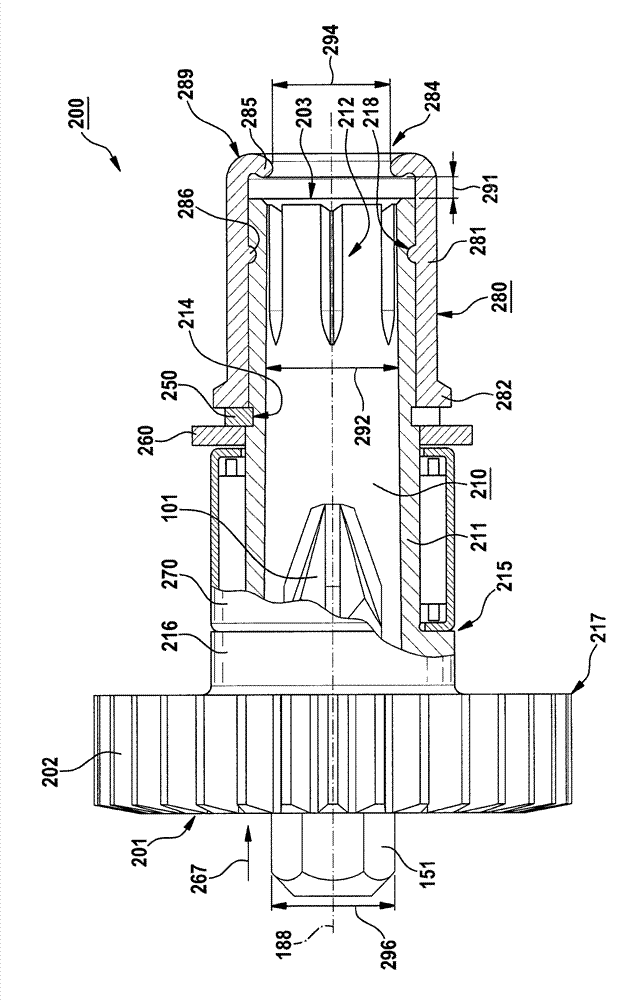

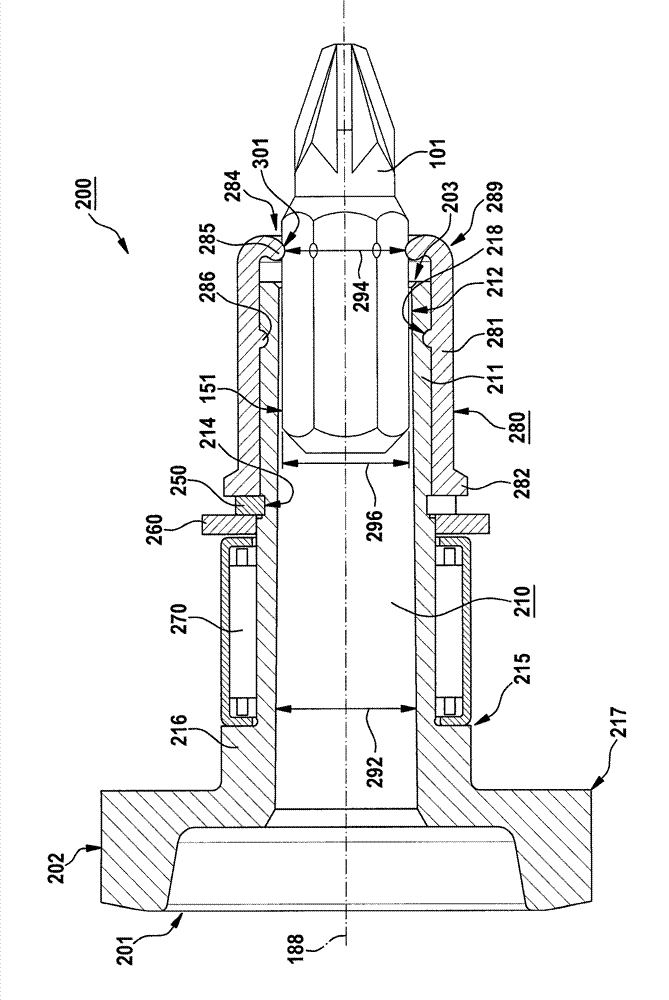

[0042] According to one specific embodiment, the braking element 281 has a through-opening 284 for the tool 101 at its axial end region facing away from the flange-shaped section 282 , through which the tool 101 is pushed After being inserted into the inner receptacle 210, it is held firmly in the associated tool operating position. In the region of this through-opening 284 , the detent element 281 has, as shown, a hook-shaped end region 289 , so that when the tool 101 is pushed into the through-opening 284 because the tool 101 is pushed into the inner receiving Part 210 produces braking friction on tool 101 .

[0043] The hook-shaped end region 289 is preferably made of an elastomer, in particular rubber, and is used for pushing the tool 101 into the through-opening 284 and thus into the hook-shaped end region 289 by elastic deformation. At this time, an elastic force for braking the tool 101 is generated. For this purpose, the hook-shaped end region 289 has an almost annul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com