Step-type slope protection grass planting brick die

A grass-planting brick and step-type technology, applied in the field of mold manufacturing, can solve the problems of single structure, inability to adjust the inclination, and inability to guarantee the compaction of grass-planting bricks, and achieve the effect of beautifying the environment, protecting the land, and protecting soil and water loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The mold of the present invention is used as a mold for producing stepped grass-planting bricks for slope protection, and the present invention will be described in detail below in conjunction with the accompanying drawings.

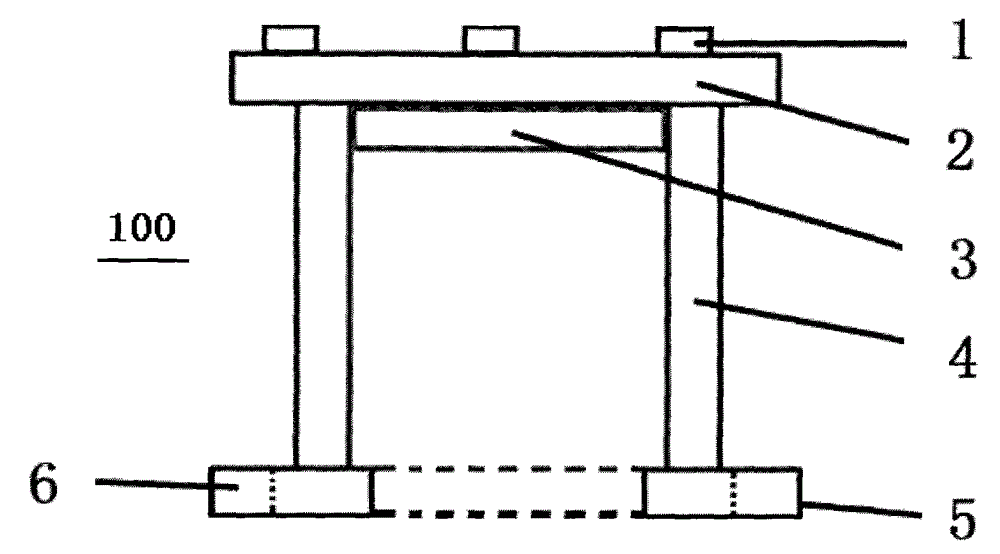

[0026] First refer to figure 1 , figure 1 It is a structural schematic diagram of the mold indenter 10 () of the present invention. The mold indenter 100 includes an indenter positioning screw 1, a universal mold interface plate 2, an indenter reinforcing rib plate 3, an indenter reinforcing rib vertical plate 4, and cement product extrusion Plate 5 and interlocking hole 6. Among them, the mold pressure head 100 is connected to the hydraulic roof of the brick making machine through the pressure head positioning screw 1, and the universal mold interface plate 2 can conveniently replace various mold pressure heads. Cement product extruded plates 5 are connected to each other, and the pressure head stiffener vertical plate 4 also bears the pressure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com