Environment structure for suspension frame of vehicle

A frame and structure technology, applied in the field of peripheral structure, can solve the problems that cannot fully bear, cannot withstand load and vibration, cannot use the rigidity of the suspension frame, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

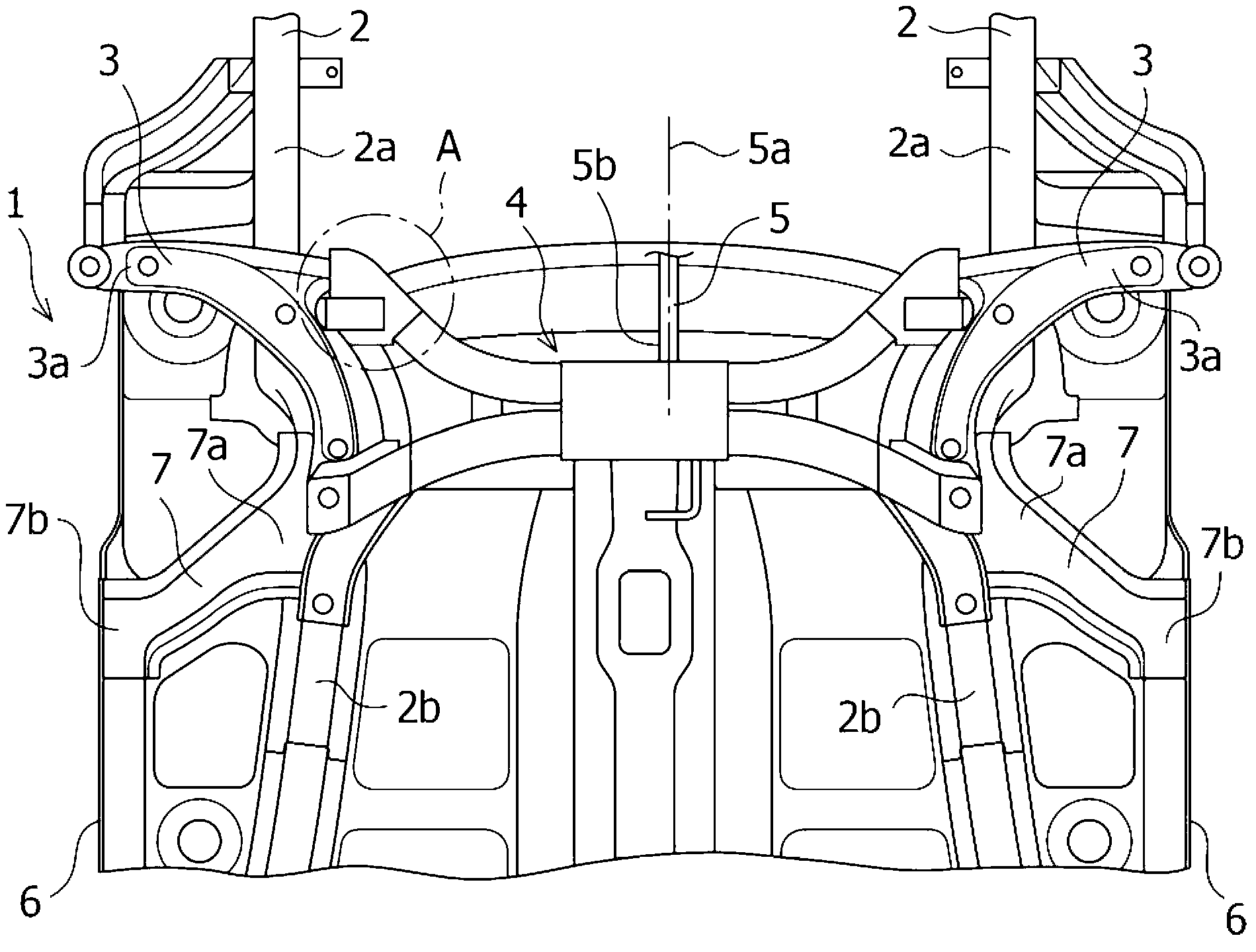

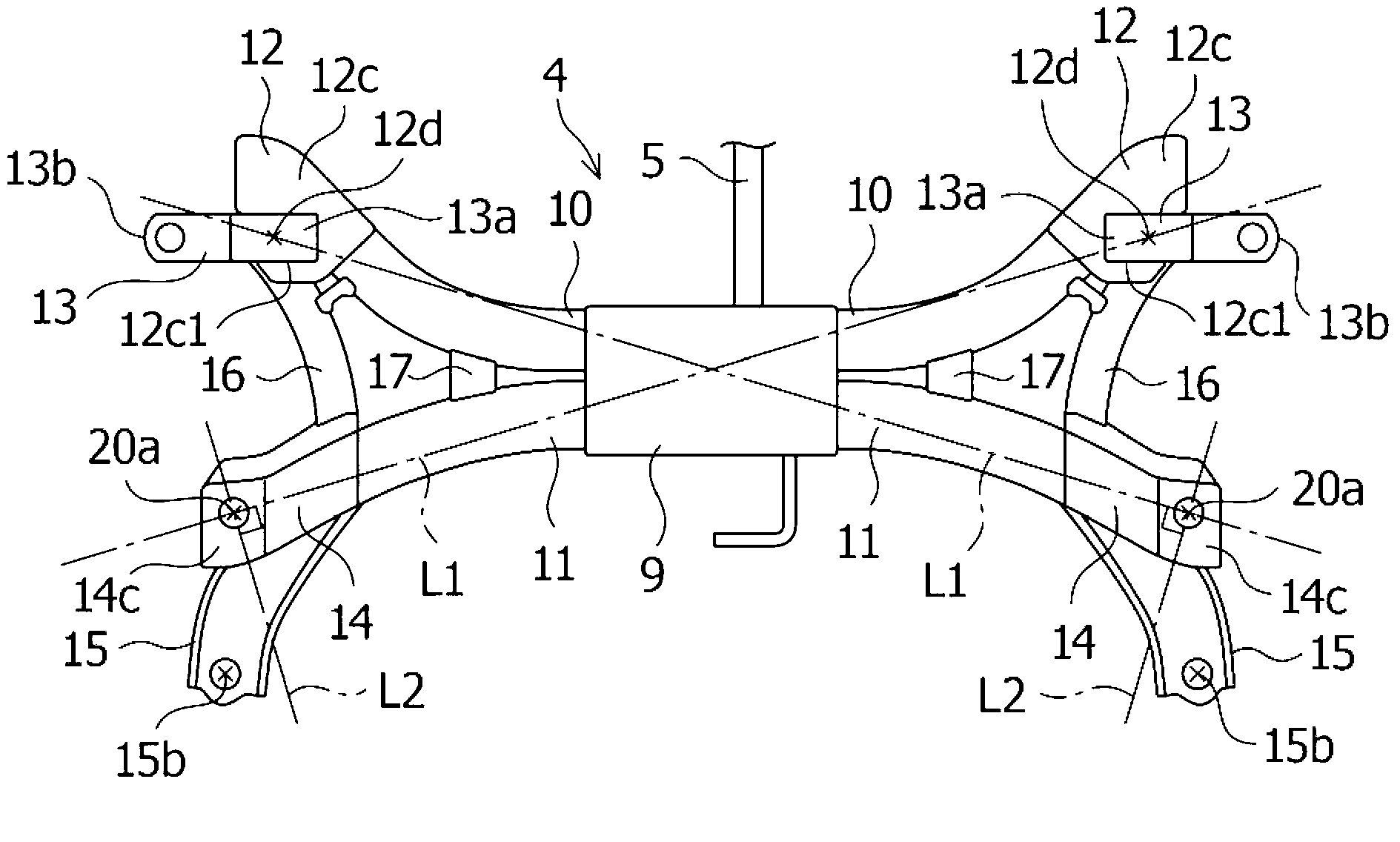

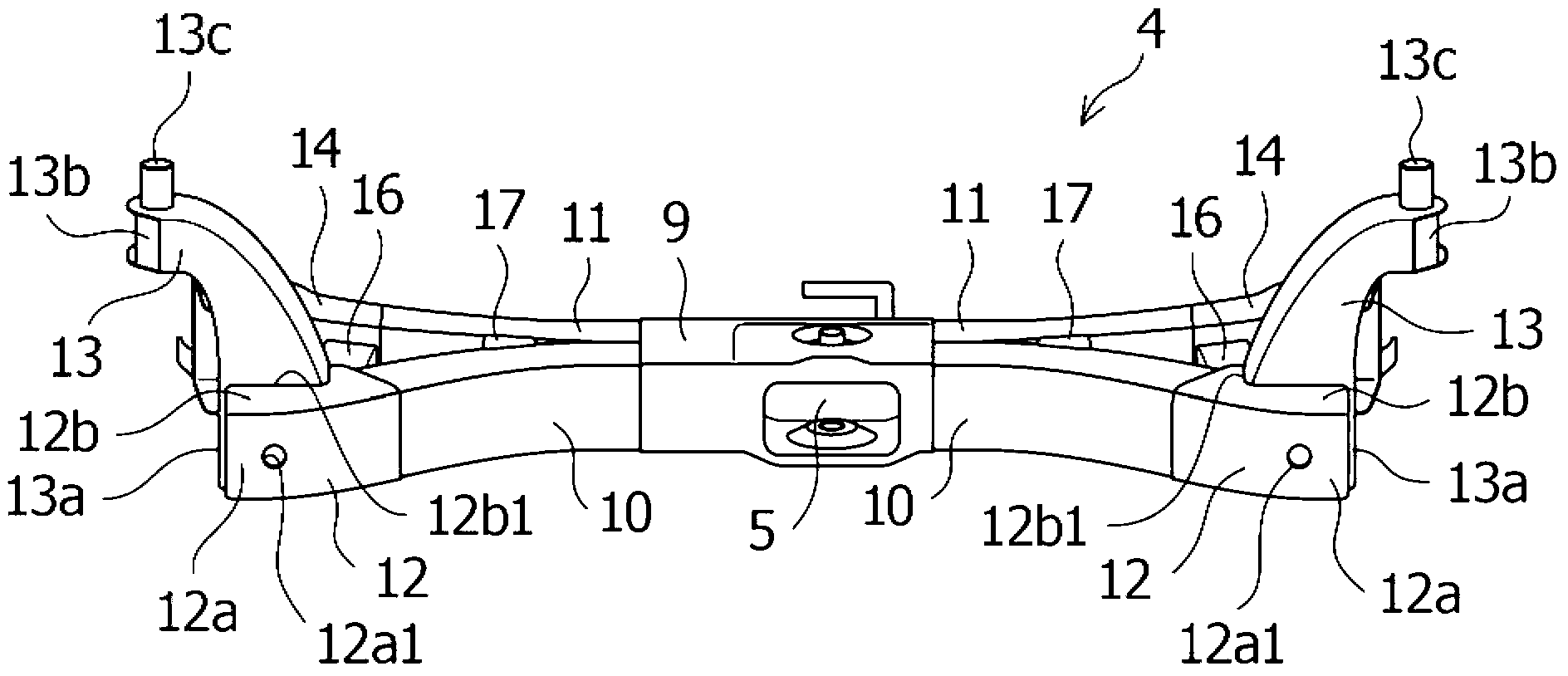

[0020] Next, the peripheral structure of the suspension frame according to the embodiment of the present invention will be described. In addition, this embodiment will be described using the vehicle body front portion of a front-engine front-wheel drive (FF) system vehicle.

[0021] refer to figure 1 A pair of side frames 2 constituting a frame of the vehicle body are provided on the vehicle body front portion 1 , and the pair of side frames 2 are arranged along the vehicle front-rear direction and at a distance from each other in the vehicle width direction. A pair of lower arms 3 constituting a suspension mechanism are provided in the vehicle body front portion 1 , and the lower arms 3 are arranged below the side frame 2 . In addition, a suspension frame 4 is disposed between the pair of side frames 2 . Although not particularly shown, drive mechanisms such as an engine and a transmission are arranged on the front side of the suspension frame 4 , and side frames 2 are arra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com