Hexagonal rolling mechanism

A technology of hexagonal and transmission components, which is applied in the field of single-degree-of-freedom mobile mechanisms, can solve problems such as mechanism asymmetry and poor motion performance, and achieve the effects of increased strength, low cost, and increased stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

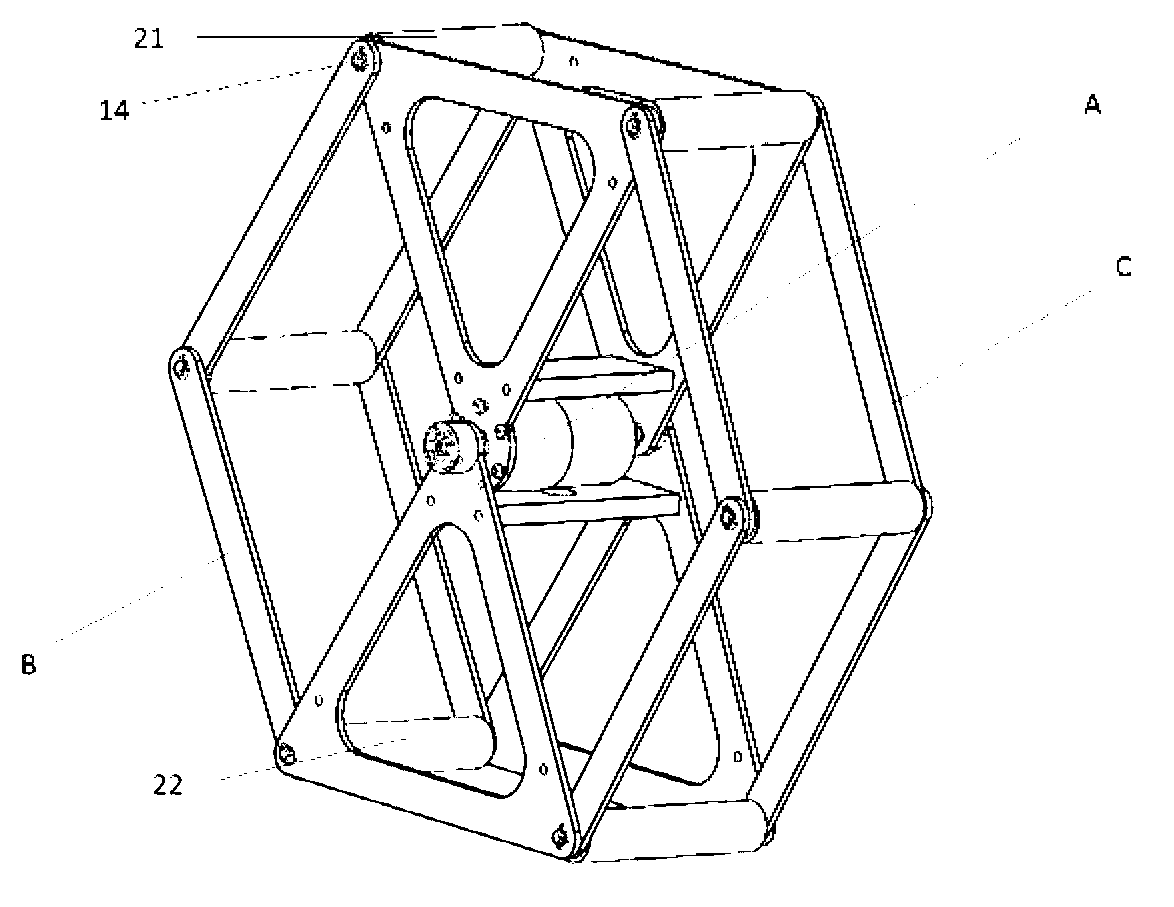

[0027] figure 1 The overall mechanism shown includes an intermediate transmission assembly A, a left connecting assembly B, and a right connecting assembly C.

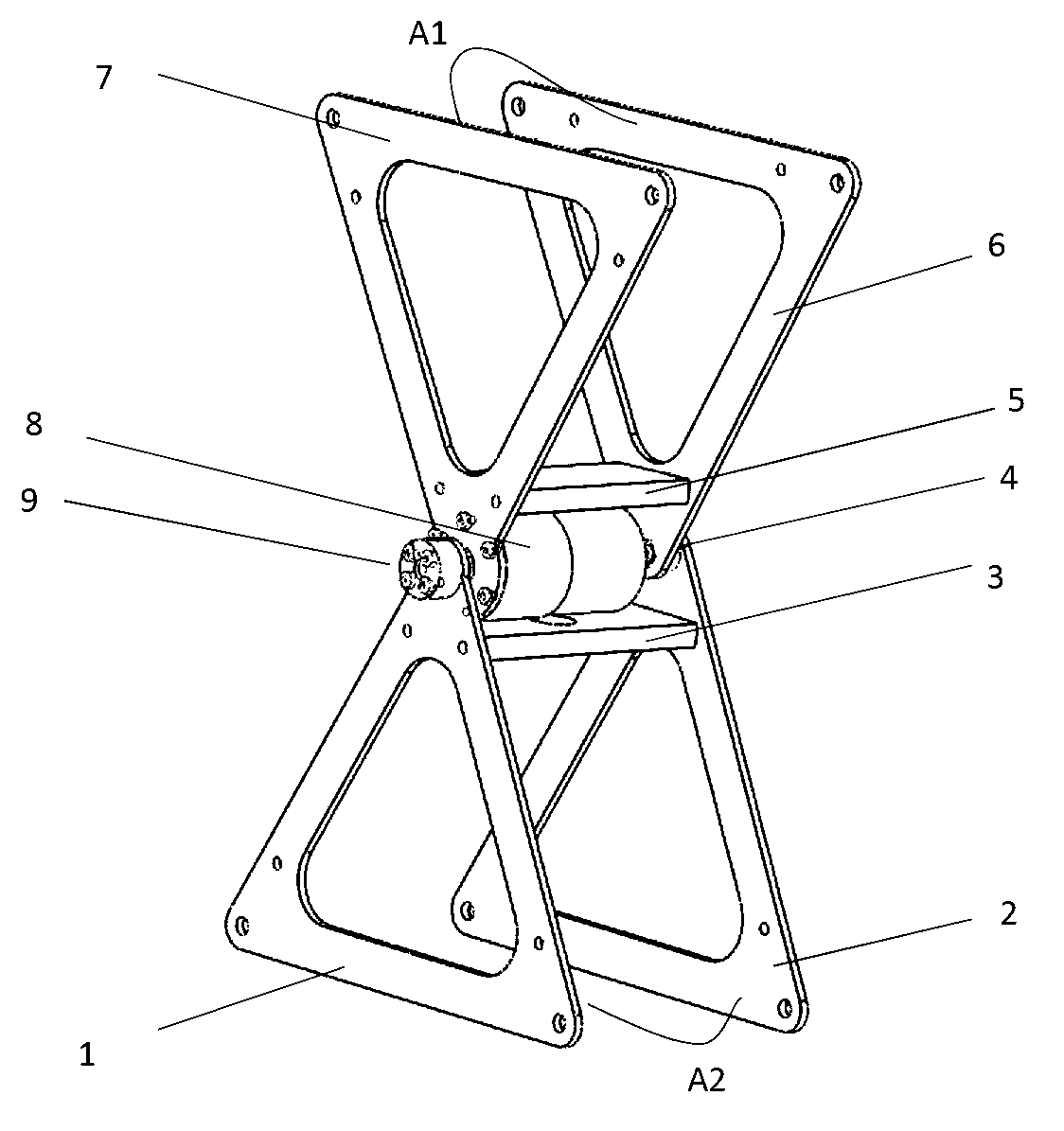

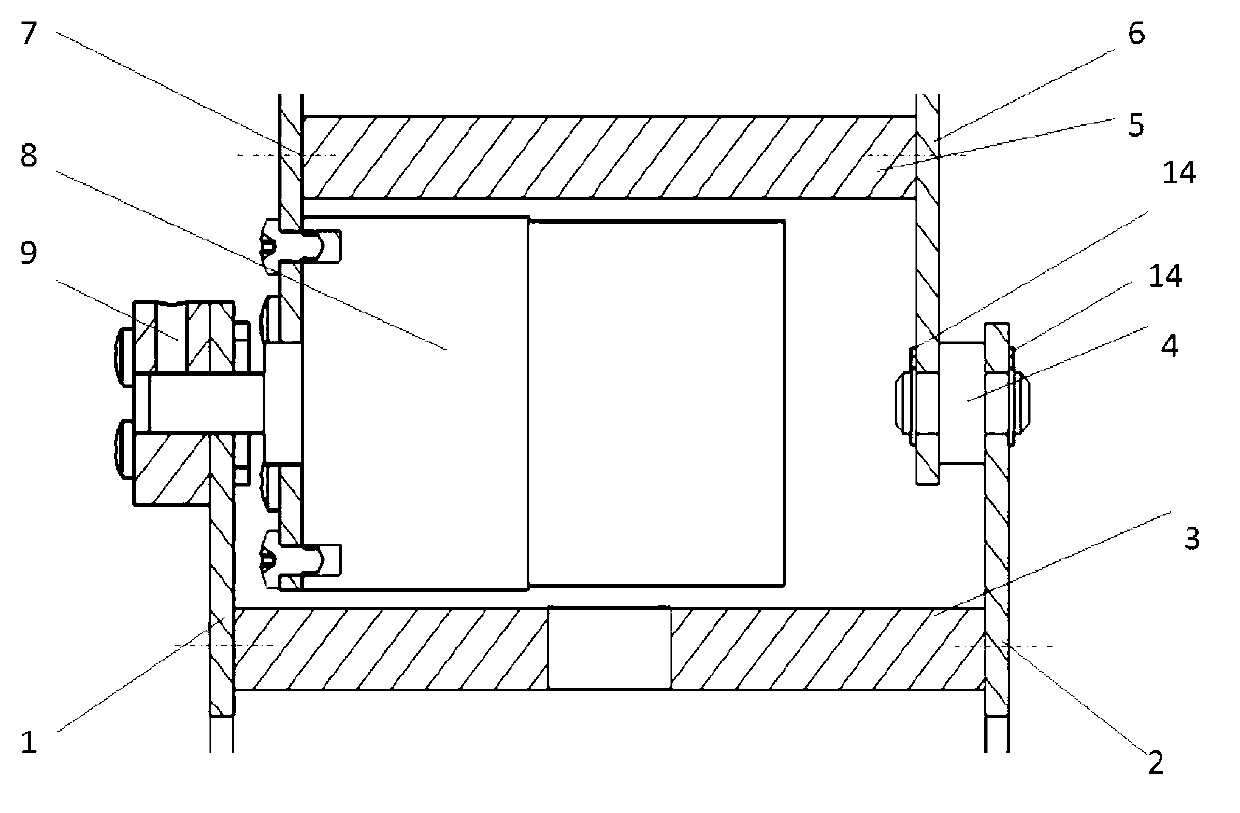

[0028] figure 2 Shown is the intermediate transmission assembly A. The intermediate transmission assembly A consists of four triangular pieces (1, 2, 6, 7), two connecting blocks (3, 5), a short shaft (4), a motor (8), and a coupling The device (9) is composed of a spring retaining ring (14) for the shaft. image 3 Shown is a sectional view of the intermediate transmission assembly A, the triangular pieces (1, 2) and the connecting block (3) are fixed together by screws, and the triangular pieces (6, 7) and the connecting block (5) are fixed together by screws; the motor ( 8) Installed on the triangular piece (7), the coupling (9) and the triangular piece (1) are fixedly connected by screws, and the shaft of the coupling (9) and the motor (8) are driven by the top wire; the short shaft ( 4) Actively connect the tri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com