Method for preparing silicon-titanium aluminum oxide by carrying out deferrization on coal ash in activating way

A technology of fly ash and alumina, which is applied in the field of silicon-titanium-alumina, can solve the problems of volatile, reducing, aluminum loss, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0026] The fly ash produced by Tianjiaan Power Plant in Huainan, China was used as the raw material, and its chemical composition is listed in Table 1.

[0027] Table 1 Chemical composition of fly ash

[0028] Fe 2 o 3 al 2 o 3 SiO 2 CaO MgO TiO 2 burn reduction 3.99 33.00 58.40 2.70 1.60 0.24 1.25

[0029] The unit in the table is: mass percentage

[0030] Weigh 10 g of mechanically ground fly ash (particle size less than 30 microns) into a polytetrafluoroethylene beaker, and add 140 mL of NaOH solution with a concentration of 25% by mass. Keep the reaction at 90°C for 2.5 hours in a water bath with a stirrer, filter with suction, wash, and dry to obtain activated fly ash.

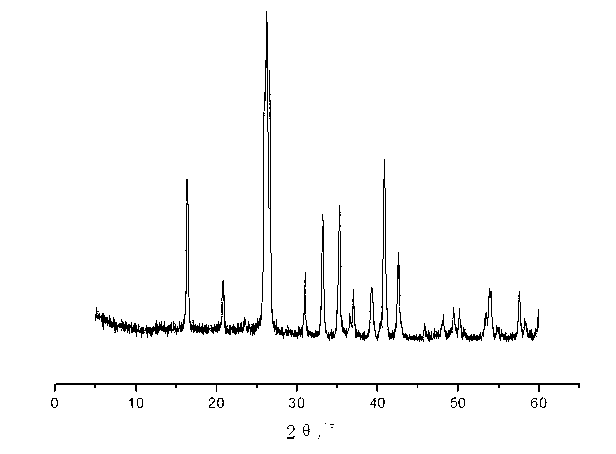

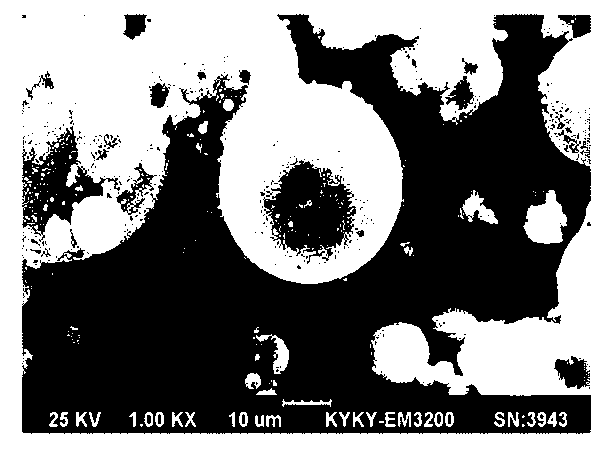

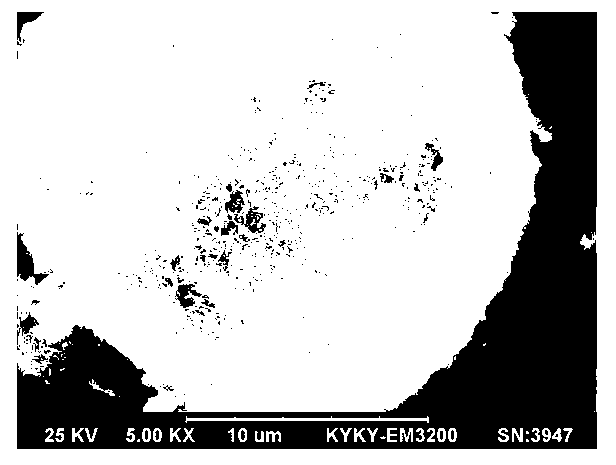

[0031] Depend on figure 1 and figure 2 By comparison, it can be seen that the smooth glass phase layer on the original particle surface has basically disappeared, and the mineral components wrapped by the glass phase are exposed on the surface. At the same ...

Embodiment 2

[0047] Example 2 is basically the same as Example 1, except that in step 1, the concentration of NaOH is 20% by mass, the temperature is kept at 100° C., and the reaction is stirred for 3.0 hours. In step 2, the leaching temperature is 80° C., and the leaching time is 2 hours. The mixed acid used contains the sulfuric acid of 70g of oxalic acid and 0.023mol in every liter of mixed acid solution.

Embodiment 3

[0048] Example 3 is basically the same as Example 1, except that in step 1, the concentration of NaOH is 30% by mass, the temperature is maintained at 80° C., and the reaction is stirred for 2.0 hours. In step 2, the leaching temperature is 60° C., and the leaching time is 4 hours. The mixed acid used contains 50 g of oxalic acid and 0.5 mol of sulfuric acid in every liter of mixed acid solution.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap