Movable hanger operating platform and manufacturing, installing, using and removing methods thereof

An operating platform and mobile technology, which is applied in the erection/assembly of bridges, bridges, buildings, etc., can solve problems such as construction inconvenience and falling objects from high altitudes, and achieve the effects of avoiding material loss, reducing capital waste, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] In order to make the technical features of the present invention more easily understood, the technical solutions of the present invention are described in detail below with reference to the accompanying drawings and in conjunction with the embodiments:

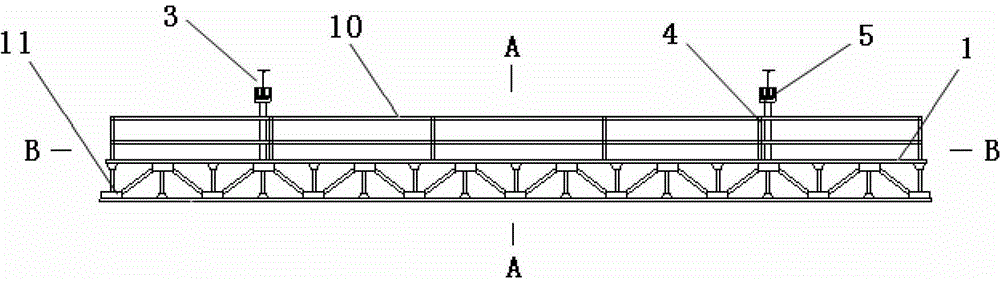

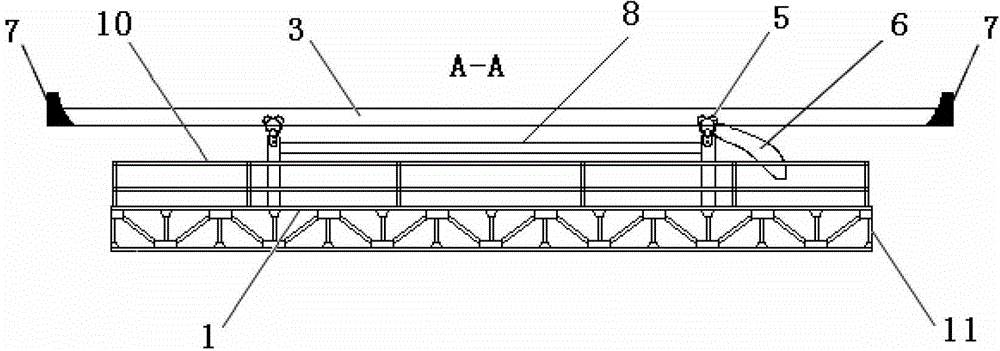

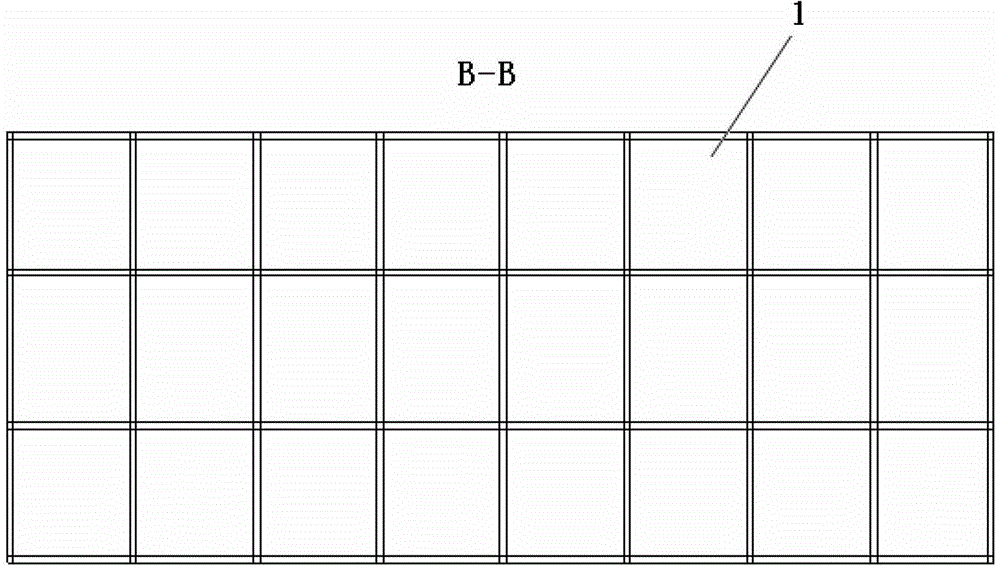

[0041] refer to figure 1 , figure 2 , image 3 , the mobile hanger operating platform of the present invention includes a truss chassis 11 welded with section steel, and two pairs of longitudinally symmetrical connecting rods 4 are welded with transverse symmetry on the truss chassis 11, and each pair of connecting rods 4 Crosspieces 8 are arranged between the rods 4 to make them stable, and the upper ends of each connecting rod 4 are respectively provided with a monorail trolley 5 that can form a kinematic pair with the maintenance track 3 that comes with the steel truss girder. The monorail dolly 5 is provided with an inverted chain 6 .

[0042] The distance between the two pairs of connecting rods 4 welded transv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com