High pressure resistant composite diaphragm for high pressure diaphragm pump

A high-pressure diaphragm and high-pressure-resistant technology, which is applied to components, pumps, and pump components of pumping devices for elastic fluids, can solve problems such as wear of pistons and hydraulic cylinders, limit application fields, and cannot be used to achieve good sealing The effect of performance, versatility, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The following examples are further explanations and illustrations of the present invention, and do not constitute any limitation to the present invention.

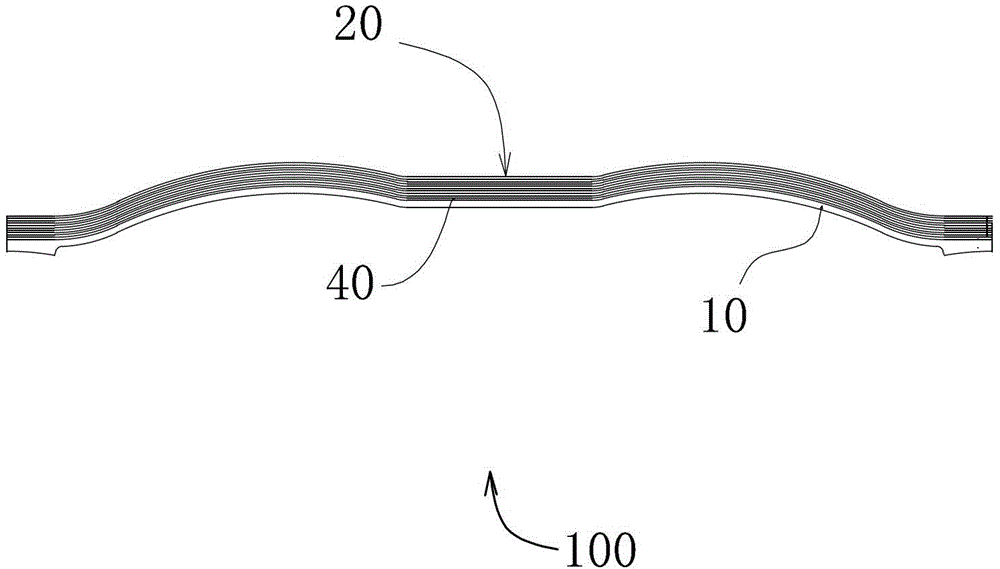

[0021] refer to figure 1 , Figure 5 , The high-pressure resistant composite diaphragm 100 of the high-pressure diaphragm pump of the present invention includes a non-metallic elastic sealing diaphragm 10, a metal elastic diaphragm 20, a liquid chamber 31 and a metal elastic diaphragm 40 with holes in the high-pressure diaphragm pump.

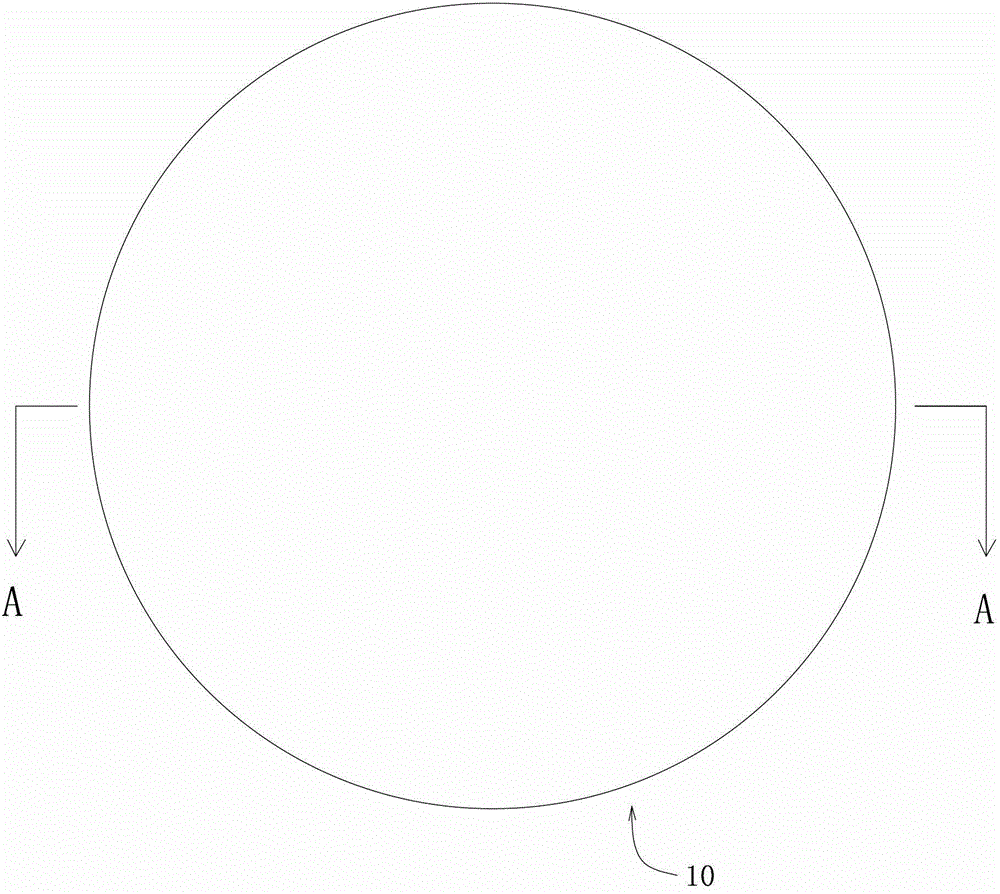

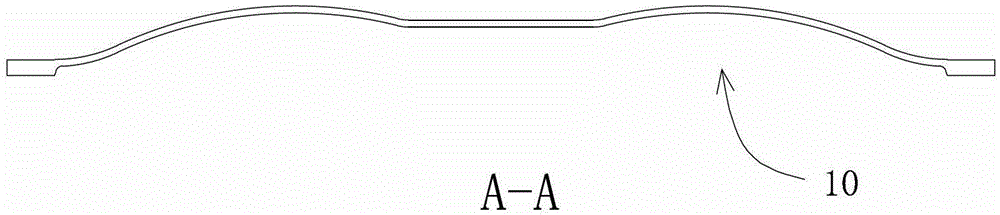

[0022] Such as Figure 2A , Figure 2B As shown, the non-metallic elastic sealing diaphragm 10 is a circular diaphragm made of deformable non-metallic material, such as rubber, plastic, etc., which is sealed and connected to the liquid chamber 31 of the high-pressure diaphragm pump 30 by conventional methods. The opening is used to isolate and seal the liquid chamber 31 from diaphragms, pressure heads and other components.

[0023] Such as figure 1 , one or more layers of metal ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com