Method for testing vibration acceleration of sensor at 100g or above

A technology of vibration acceleration and sensors, applied in instruments, measuring devices, and measuring ultrasonic/sonic/infrasonic waves, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

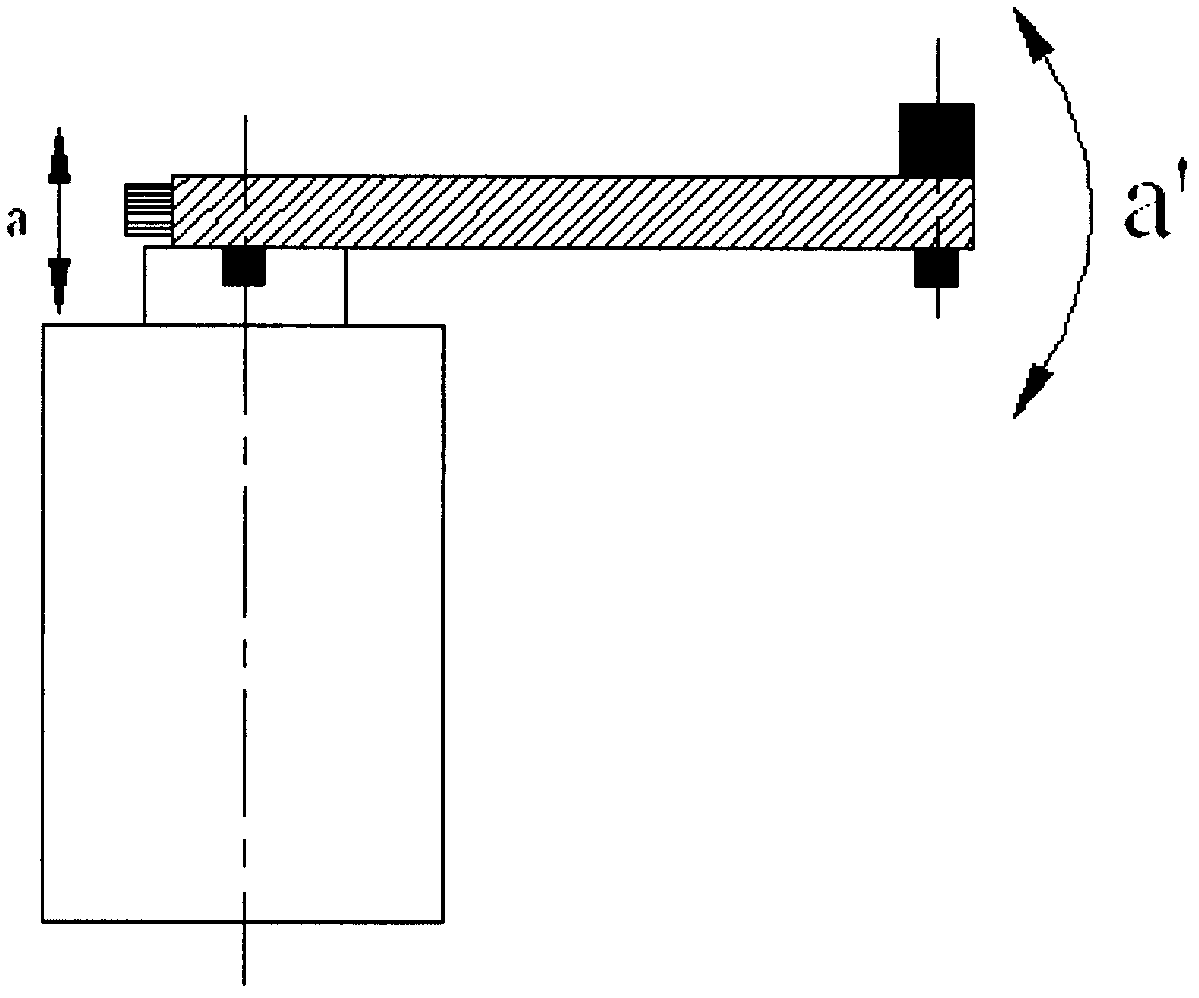

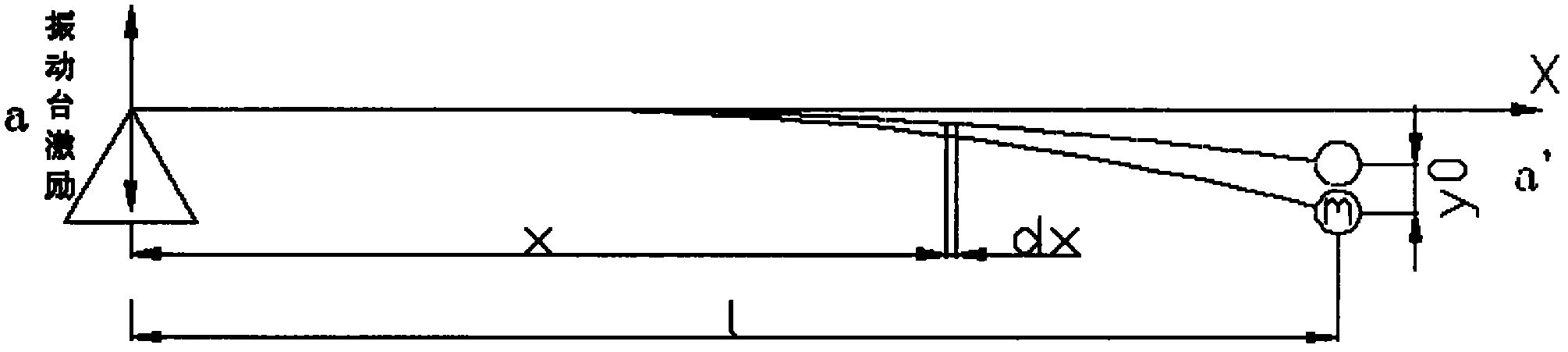

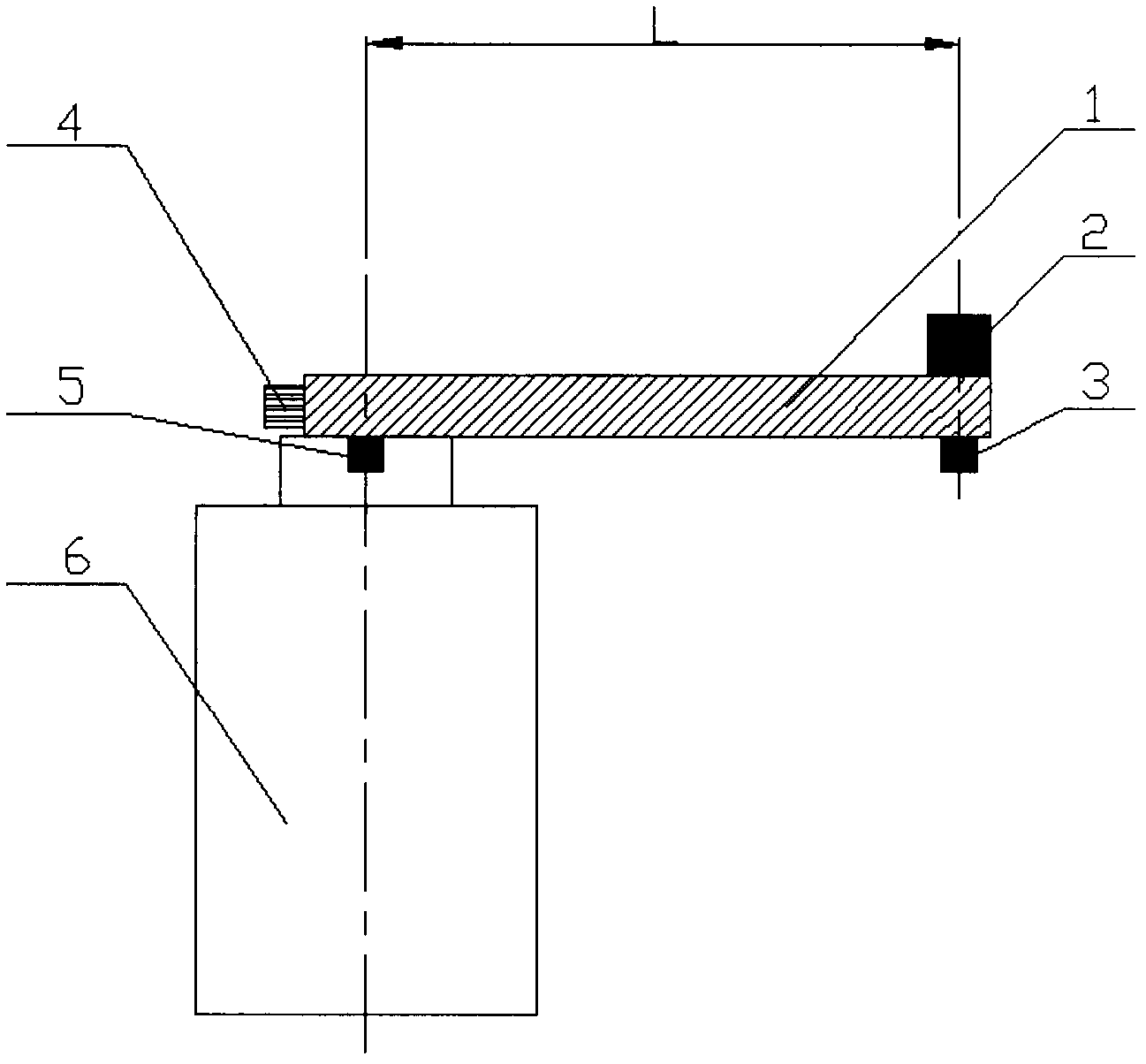

[0014] refer to figure 1 . In the best embodiment provided below, the cantilever beam and the mass block component unit are composed of a metal-processed cantilever beam 1 and a sensor under test 2, wherein the cantilever beam is made of metal, and the mass block component unit is the sensor under test .

[0015] The cantilever beam is rigidly connected to the vibrating table, and the mass block unit is fixedly connected to the free end of the cantilever beam 1 to form a vibrating table excitation vibration amplification mechanism (hereinafter referred to as vibration excitation device). The basic principle of this mechanism is to apply a vibration acceleration a to the cantilever beam at the natural frequency point frequency of a certain cantilever beam, and obtain a maximum acceleration a' of about 30 times a after resonance is generated. At the application end of the vibration table, use the vibration table to apply a vibration acceleration of less than 100g. Under the re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com