Equipment with resistance measurement device and method for measuring carbon brush contact resistance

A resistance measurement and equipment technology, which is applied in the industrial or medical field, can solve the problems of buried safety hazards, untimely regular replacement, waste of manpower and cost, etc., and achieve the effect of avoiding safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

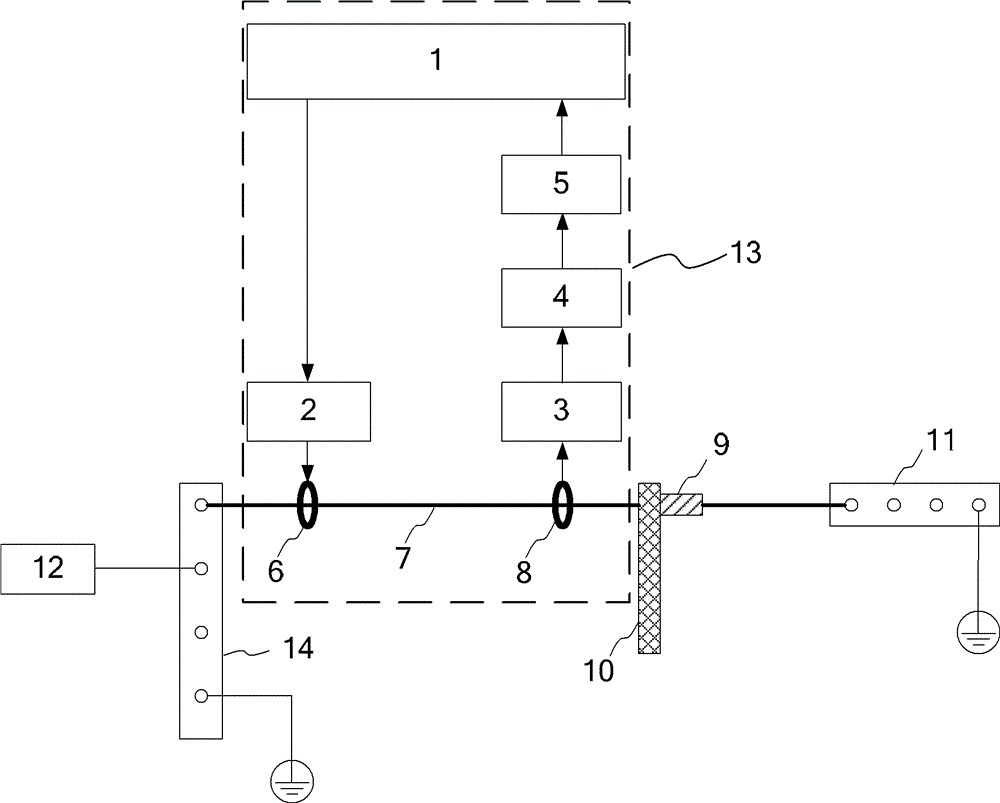

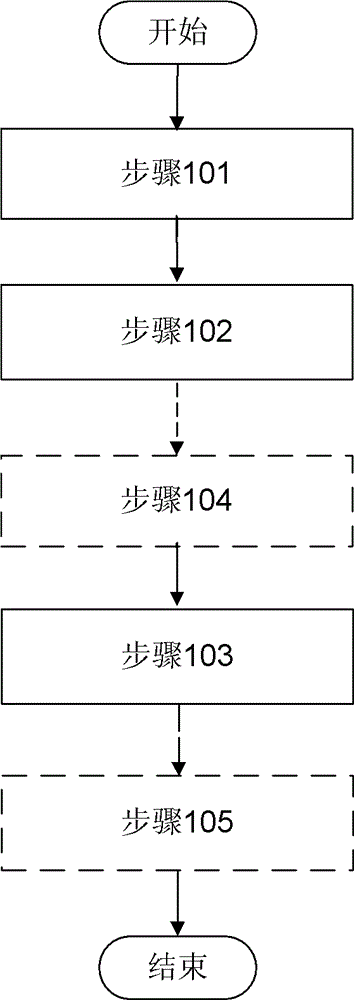

[0027] The invention provides a device with a resistance measuring device and a method for measuring carbon brush contact resistance. The carbon brush contact resistance of a slip ring system is measured within a fixed time interval to ensure that it does not exceed 0.1Ω, thereby reducing or avoiding potential safety hazards.

[0028] figure 1 It is a schematic diagram of the equipment with a resistance measuring device of the present invention. The equipment includes a frame rotating part, a slip ring system 10 and a grounding wire 7 connected to the slip ring system 10, wherein the frame rotating part is grounded through the slip ring system 10 and the grounding wire 7, and the resistance measuring device 13 is connected to the slip ring system 10 . figure 1 The left side of the rack shows the rotating part of the rack with the grounding row 14 and the rotating element 12 of the rack rotating part, figure 1 The right side of the frame shows the static part of the frame wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com