Adaptive adjustment method of steel production

An adaptive adjustment and steel technology, applied in data processing applications, instruments, manufacturing computing systems, etc., can solve the problems of not being able to achieve a good match between the production rhythm and the demand rhythm, and achieve the effect of full utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

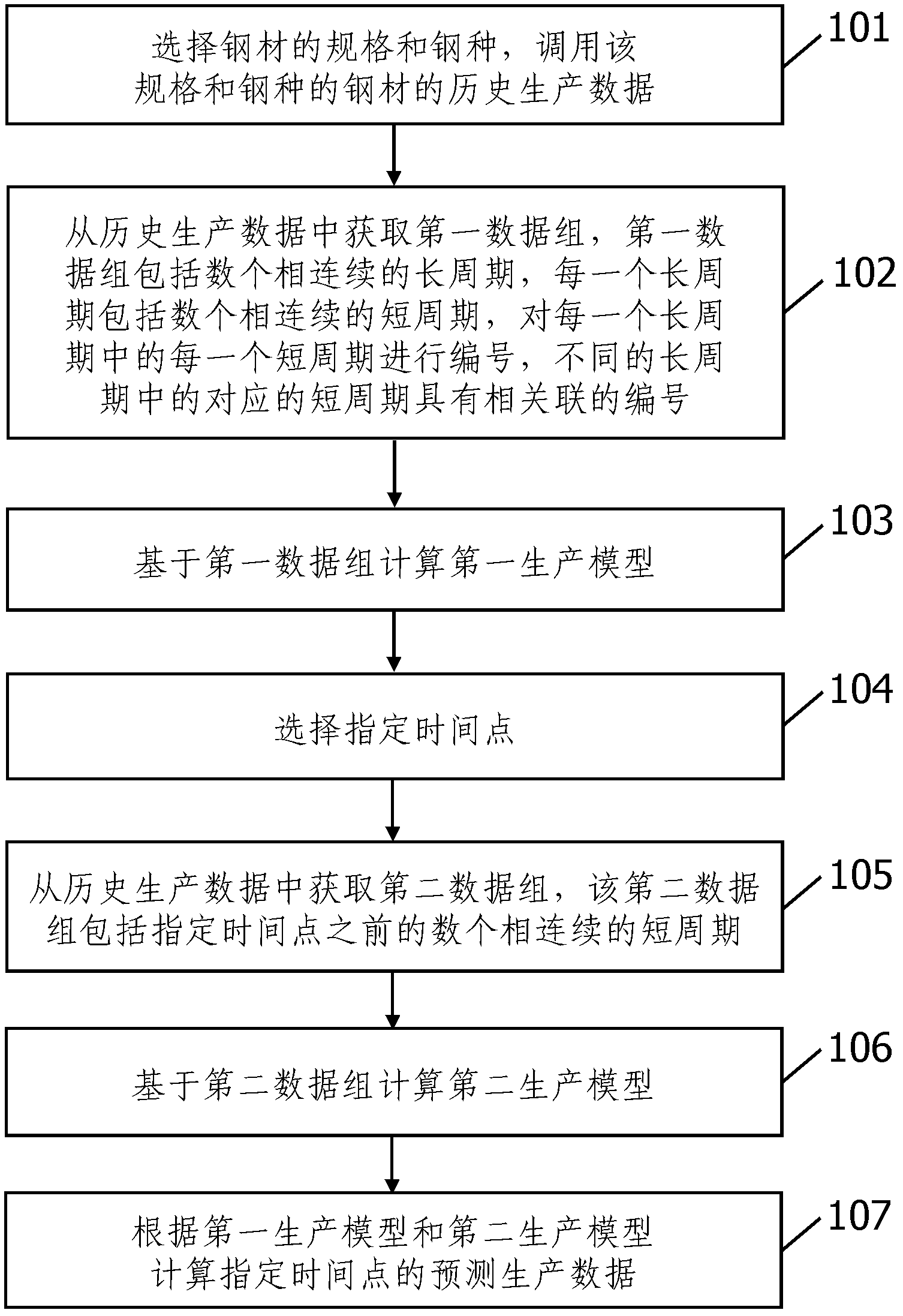

Method used

Image

Examples

no. 1 example

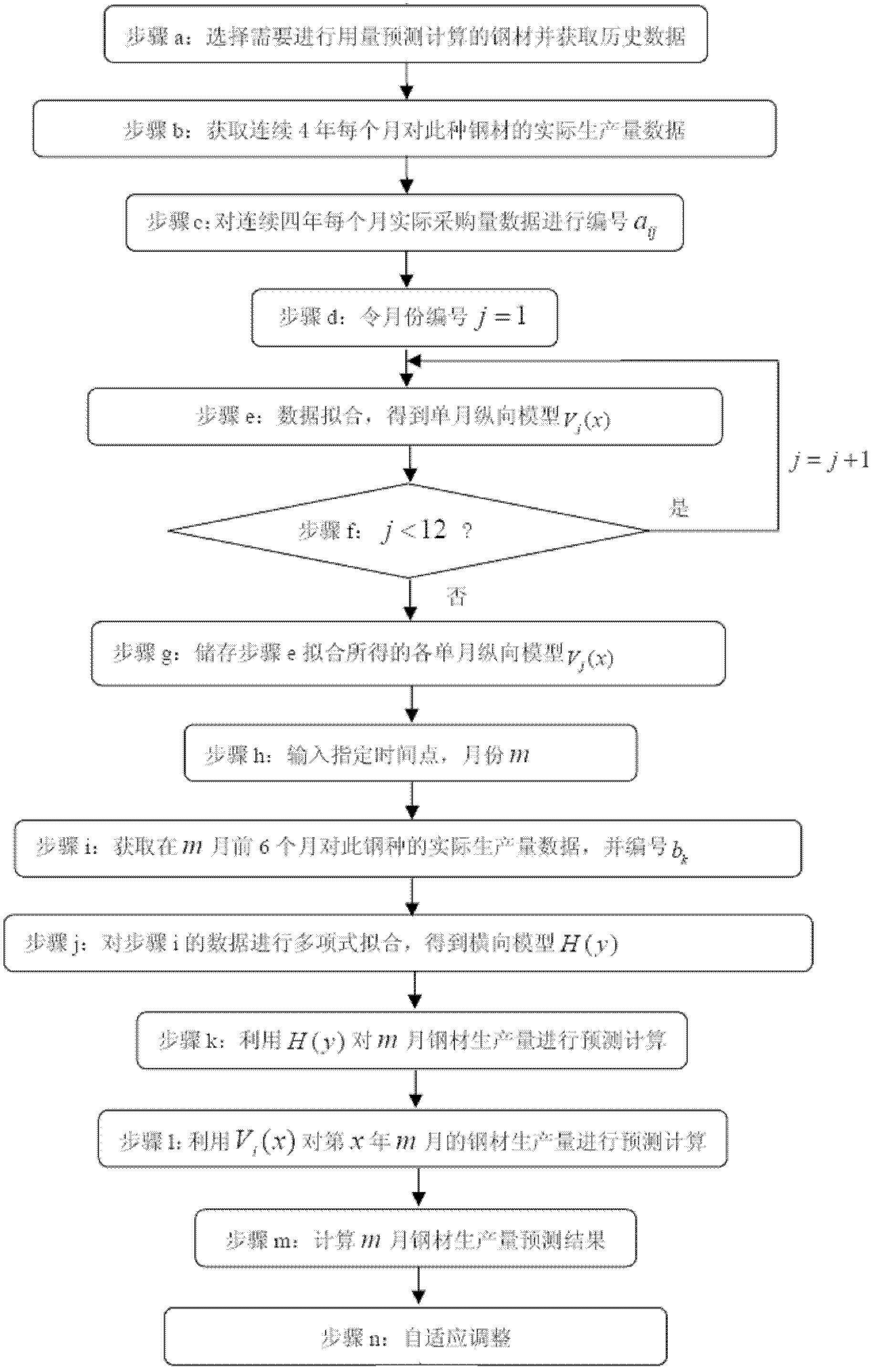

[0083] In step a), the hot-dip galvanized sheet with a specification of 0.70mm×1170mm that needs to be predicted is selected, and the historical production data of the hot-dip galvanized sheet with a specification of 0.70mm×1170mm is obtained.

[0084] In step b), the actual production data of this steel product for each month in 4 consecutive years (2008-2011) including 2011 is obtained.

[0085] In step c), number the actual purchase volume data for each month of the 4 years a ij , where a 11 = 1460, a 12 = 1580, a 13 = 1980, ...; a 21 =1550,a 22 = 1610, a 23 = 1970, ...; a 31 =1430,a 32 = 1520, a 33 = 1830, ...; a 41 = 1410, a 42 = 1670, a 43=1870, . . . Among them, i=1, 2, 3, 4, representing the first year (2008) and the second year (2009); j=1, 2, ..., 12, representing 1 to 12 months in each year respectively) .

[0086] In step d), let j=1.

[0087] In step e), using a 11 、a 21 、a 31 、a 41 These 4 data are subjected to polynomial fitting to obtain the ...

no. 2 example

[0098] In step a), the hot-dip galvanized sheet with a specification of 0.70mm×1580mm that needs to be forecasted is selected, and the historical production data of the hot-dip galvanized sheet with a specification of 0.70mm×1580mm is obtained.

[0099] In step b), the actual production data of this steel product for each month in 4 consecutive years (2008-2011) including 2011 is obtained.

[0100] In step c), number the actual purchase volume data for each month of the 4 years a ij , where a 11 =817,a 12 =845,a 13 =885,...;a 21 =822,a 22 =850,a 23 = 896, ...; a 31 =840,a 32 =864,a 33 = 904, ...; a 41 =853,a 42 =869,a 43 =912, . . . Among them, i=1, 2, 3, 4, representing the first year (2008) and the second year (2009); j=1, 2, ..., 12, representing 1 to 12 months in each year respectively) .

[0101] In step d), let j=1.

[0102] In step e), using a 11 、a 21 、a 31 、a 41 These 4 data are subjected to polynomial fitting to obtain the single-month longitudinal...

no. 3 example

[0113] In step a), the hot-dip galvanized sheet with a specification of 0.70 mm × 1600 mm is selected, and the historical production data of the hot-dip galvanized sheet with a specification of 0.70 mm × 1600 mm is obtained.

[0114] In step b), the actual production data of this steel product for each month in 4 consecutive years (2008-2011) including 2011 is obtained.

[0115] In step c), number the actual purchase volume data for each month of the 4 years a ij , where a 11 =225,a 12 =232,a 13 = 263, ...; a 21 =228,a 22 =235,a 23 = 259, ...; a 31 =232,a 32 =245,a 33 = 271, ...; a 41 =231,a 42 =238,a 43 =269, . . . Among them, i=1, 2, 3, 4, representing the first year (2008) and the second year (2009); j=1, 2, ..., 12, representing 1 to 12 months in each year respectively) .

[0116] In step d), let j=1.

[0117] In step e), using a 11 、a 21 、a 31 、a 41 These 4 data are subjected to polynomial fitting to obtain the single-month longitudinal model V 1 (x)=-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com