Field effect transistor gas sensor and array preparation method thereof

A field effect transistor and gas sensor technology, applied in the field of semiconductor gas sensors, can solve problems such as phase transition, increase device power consumption, and limit low-power Internet of Things

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

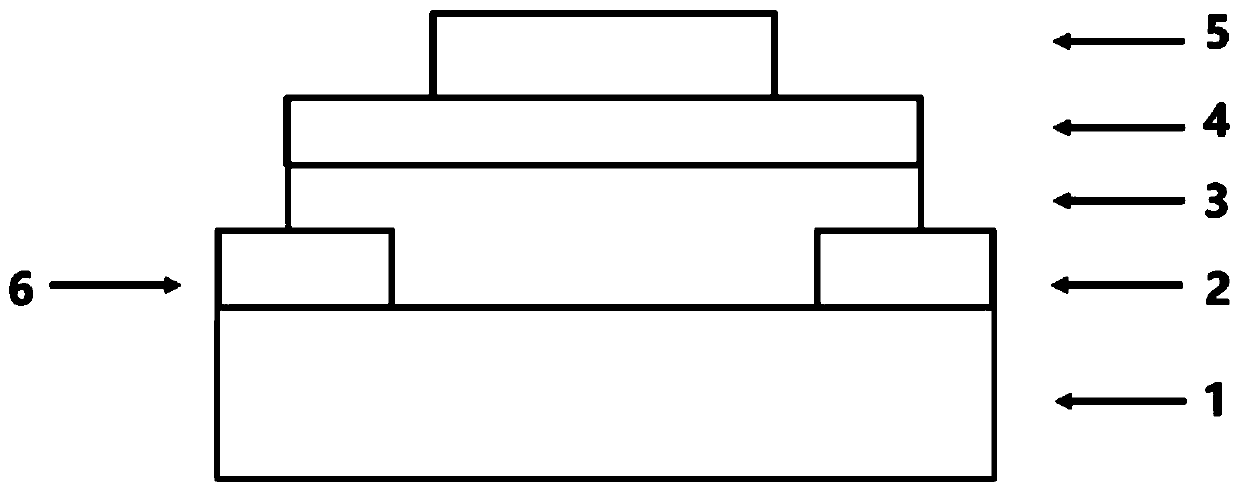

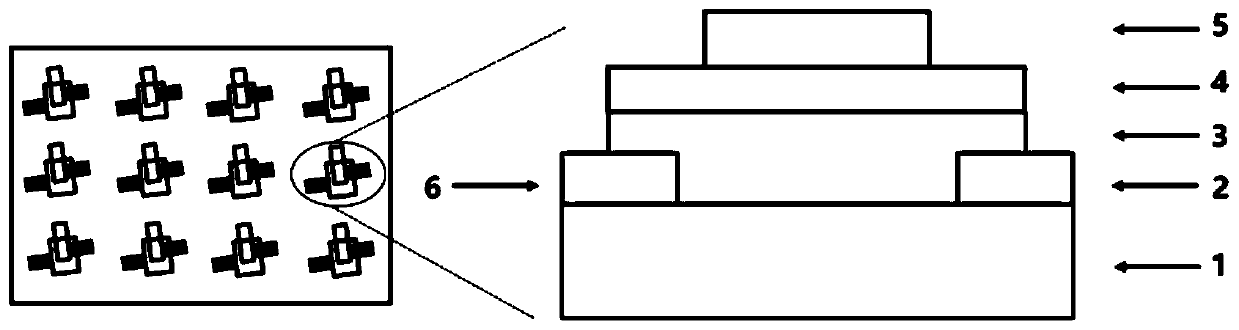

[0062] The preparation method of the grid-sensitive FET gas sensor can adopt the following steps: the quantum dot material is prepared by the colloidal method and dispersed in the liquid phase to form a colloidal quantum dot; 2 or Si / Si 3 N 4 Micro-nano electrode patterns are formed on commercial substrates through process steps such as photolithography masks, and then Ti / Au composite layers or Cr / Au composite layers or Ni / Au composite layers are deposited by physical methods such as electron beam evaporation, thermal evaporation, and magnetron sputtering Combined layer forms source, drain electrode (drain electrode and the composition material of source electrode both can be identical, for example can all be Ti / Au layer, can pass through photolithography mask at this moment, the source drain electrode of physical method deposition gained; Of course Also can be different from each other, at this moment, need pass through twice photolithography mask, physical method deposition...

Embodiment 1

[0069] This embodiment comprises the following steps:

[0070] (1) Preparation of PbS colloidal quantum dot solution. PbO can be used as the lead source, and hexamethyldisilathane (TMS) can be used as the sulfur source, which can be produced by colloid chemical reaction.

[0071] Specifically, 0.9 g of PbO can be dissolved in 5 ml of oleic acid (OA) and 20 ml of octadecene (ODE) under a nitrogen atmosphere and heated to 90° C. to prepare a precursor of lead oleate as a lead source. After evacuating for 8 hours, the temperature of the precursor was raised to 120°C. Dissolve 280 μl TMS into 10 ml ODE as a sulfur source. Quickly inject the sulfur source into the lead source at 120°C, and after the color of the reaction system turns black (about 15 seconds), put the solution into cold water to quickly drop the temperature to room temperature. Add an appropriate amount of acetone to the cooled solution, remove the supernatant after centrifugation, and then disperse with toluene ...

Embodiment 2

[0079] (1) Preparation of SnO 2 Colloidal quantum dot solution. SnCl can be used 4 ·5H 2 O was used as the tin source, and oleic acid and oleylamine long-chain organic ligands were used as encapsulating agents, which were generated by solvothermal reaction.

[0080] Specifically, 0.6g SnCl can be 4 ·5H 2 O. 20ml of oleic acid and 2.5ml of oleylamine were heated to 100°C and vacuum-dried until the reaction was clear, cooled to 60°C, taken out 10ml of ethanol and mixed evenly, then added to a stainless steel autoclave, and placed in an oven at 180°C for 3 hours. After the reaction is completed, take it out, and when it is cooled to room temperature, take out the solution in the autoclave, mix it with ethanol and centrifuge the precipitate, then disperse the precipitated product in the solvent and perform ethanol centrifugation and washing again. After drying, disperse in toluene at a concentration of 20mg / ml to obtain SnO 2 Colloidal quantum dot solution.

[0081] (2) The...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com