Furnace group energy consumption system and method in fused magnesia smelting process

A technology of fused magnesia furnace and fused magnesia, which is applied to alarms, instruments, etc., can solve the problems of lack of effective supervision, real-time management, lack of centralized monitoring and alarm of energy consumption of group furnaces, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] An embodiment of the present invention will be further described below in conjunction with the drawings.

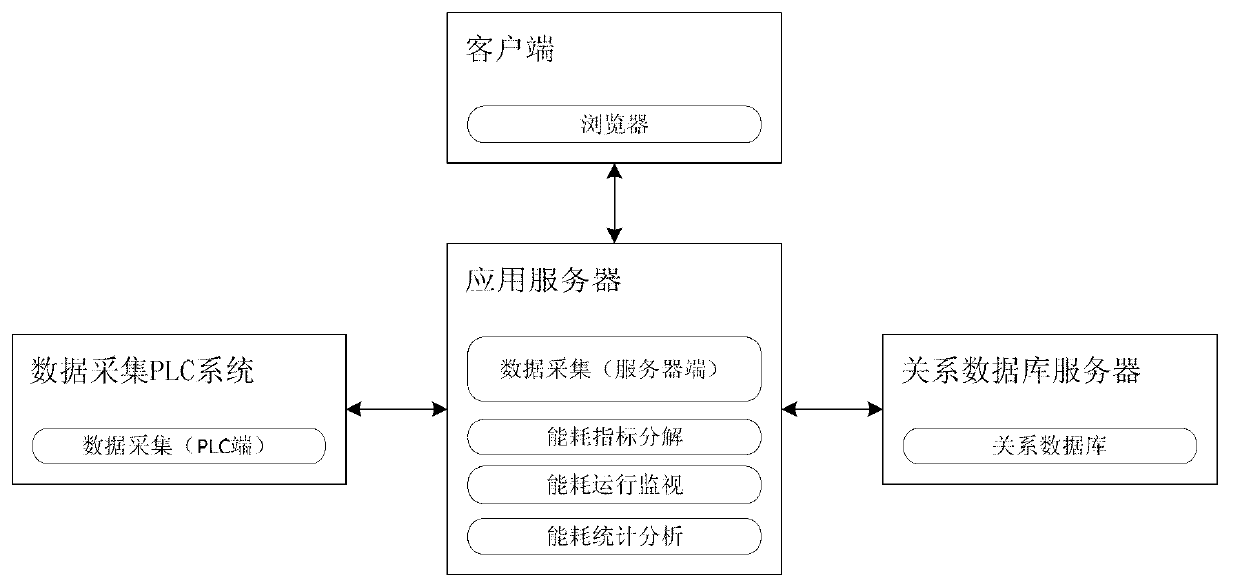

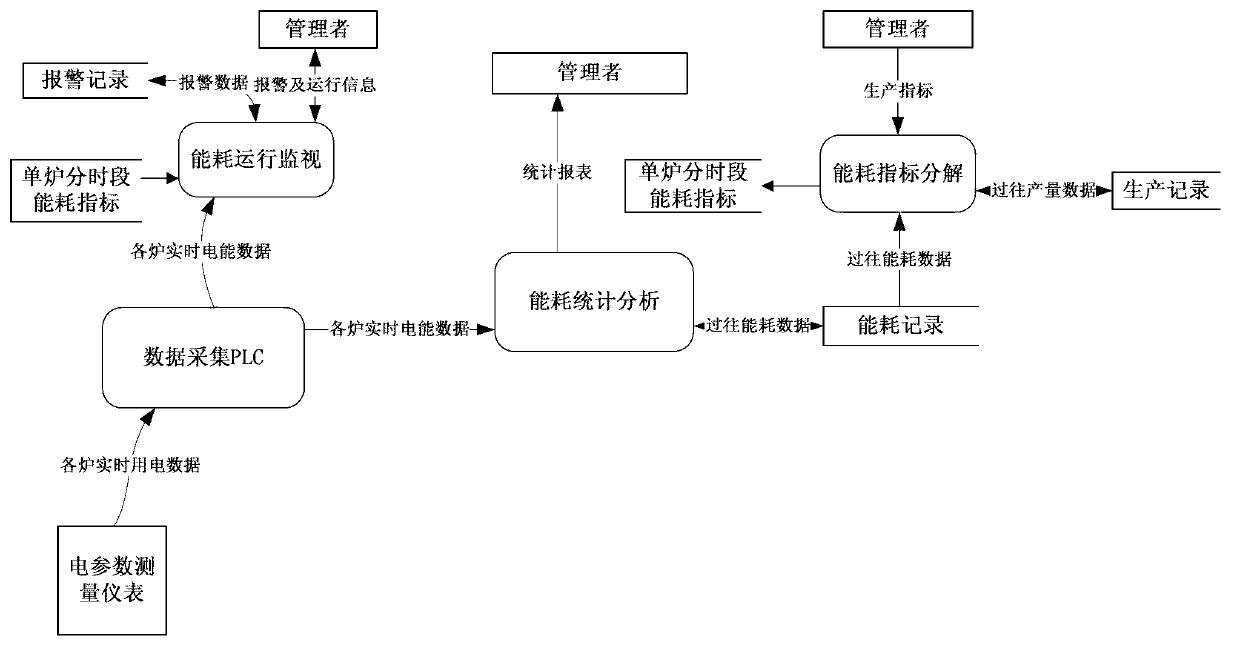

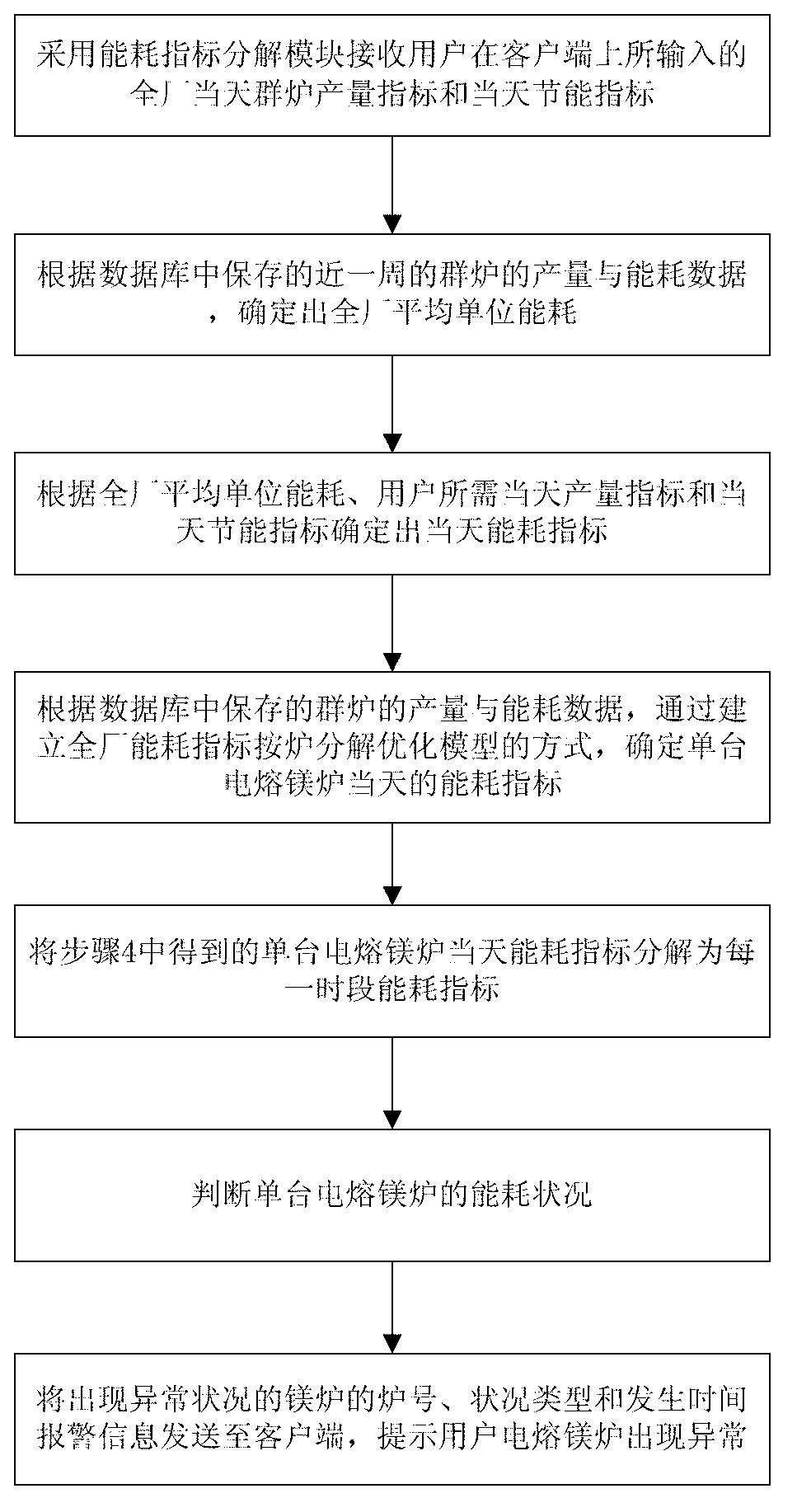

[0046] Such as figure 1 As shown, a group furnace energy consumption alarm system for fused magnesia smelting process includes a relational database server, an application server, a client and a data acquisition PLC system. The application server includes a data acquisition module and an energy consumption index decomposition module , Energy consumption operation monitoring module and energy consumption statistical analysis module. Among them, the data acquisition module is used to collect the power, active electricity measurement, power factor, electrode current and transformer secondary side voltage of the group furnace sent by the data acquisition PLC system in real time, and The above data is sent to the energy consumption operation monitoring module; the energy consumption index decomposition module is used to receive the output index and energy saving index of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com