Method for Improving Wafer Partial Exposure

A partial exposure and wafer technology, which is applied in the fields of electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve the problem of not being able to reflect the leveling and flatness status in real time, unable to fully cover the exposure of the wafer, and affecting the success rate of machine exposure And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

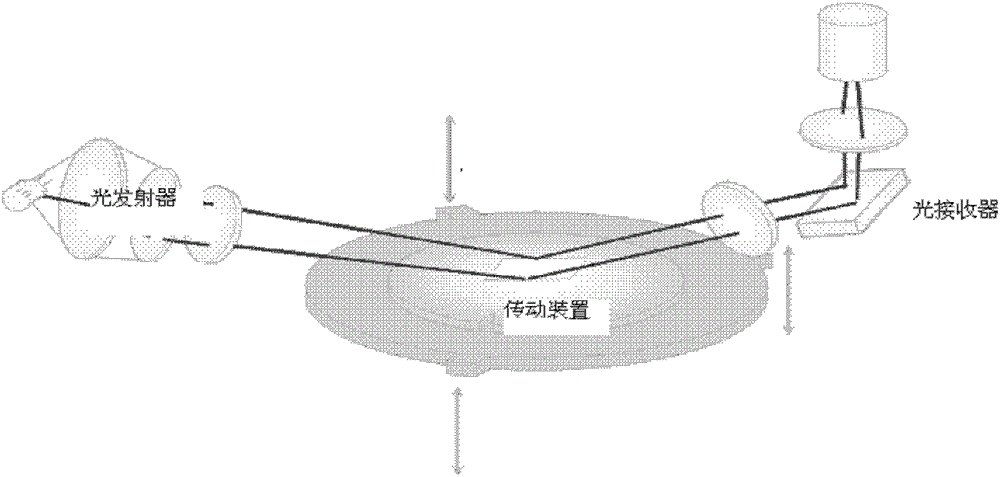

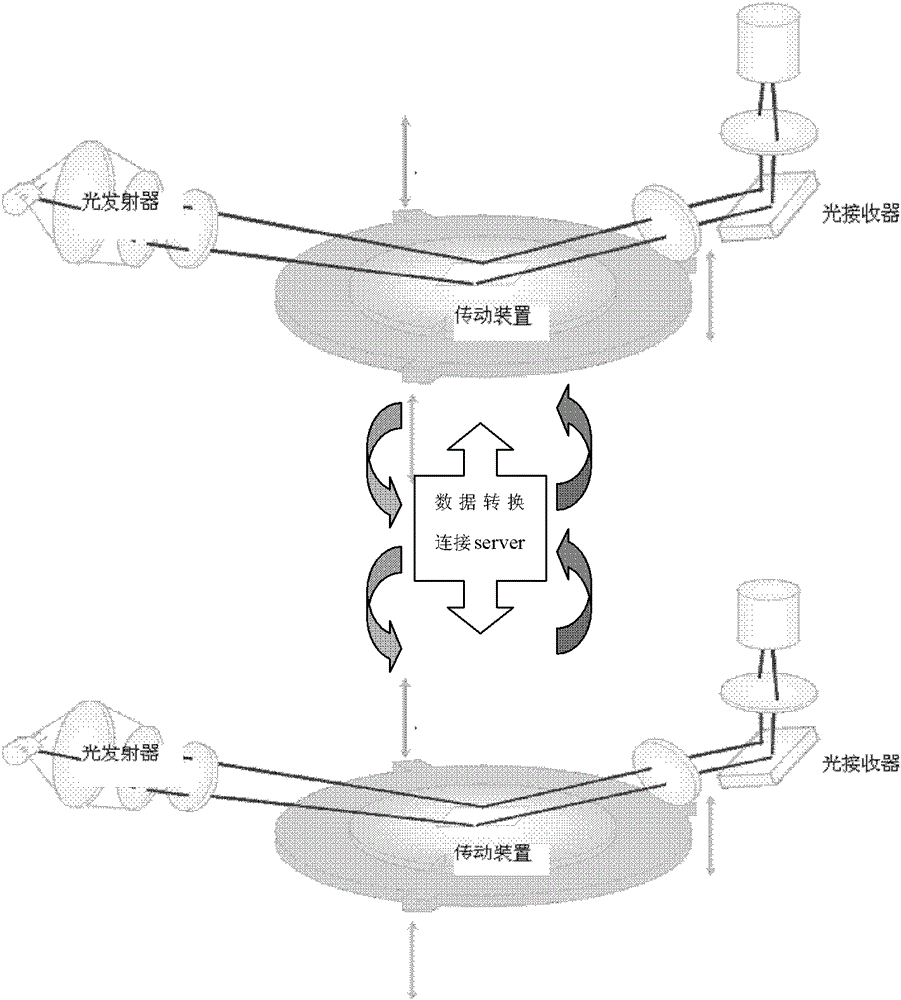

[0012] like figure 2 As shown, the present invention adds a stage of synchronous pre-alignment. The introduction of this stage reflects the state of the exposure stage of the machine in real time, and also uses real-time data to perform pre-focusing, leveling, and flatness corrections on the exposed wafer. This ensures that the wafer is in a relatively flat and stable state before exposure to light. The synchronous pre-alignment stage can reflect the state of the machine in real time, and at the same time, it can pre-correct the crystal surface and back conditions of the wafer.

[0013] The present invention is first established based on the exposure stage, and the parameters are basically the same. When one of the stages in the exposure stage or the pre-alignment stage moves in the X, Y, and Z directions, the server connected in the middle feeds back the previous state in real time. Monitor and correct as a benchmark to form a linkage structure. When the wafer is exposed, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com