Motor drive board busbar

A technology of motor drive and bus bar, which is applied in the direction of electric components, connection with control/drive circuits, electrical components, etc., can solve the problems of inconsistent electrical performance parameters, inconsistent motor phase currents, low reliability, etc. , large load capacity and consistent electrical performance parameters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

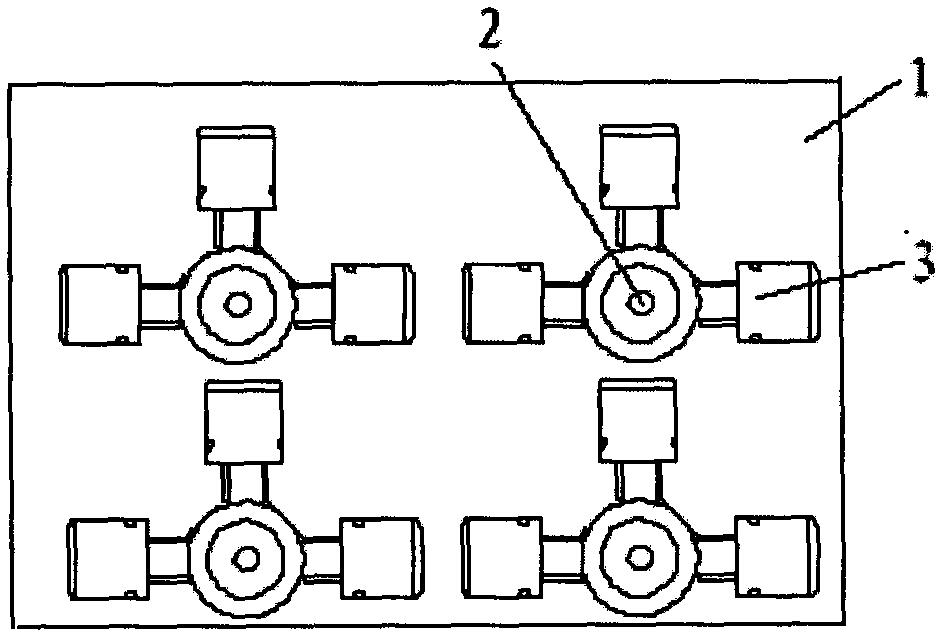

[0010] Such as figure 1 As shown, a busbar of a motor drive board includes a PCB substrate 1, on which four power terminals 2 are arranged, and each power terminal 2 is connected with three power tubes.

[0011] The bus bar of the motor driving board of the present invention has small volume and large carrying power, and the electric performance parameters of the phases of the power boards are consistent with each other.

[0012] The above descriptions are only preferred embodiments of the present invention, and are not intended to limit the present invention. Any modifications, equivalent replacements, improvements, etc. made within the spirit and principles of the present invention shall be included in the protect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com