Oriented electromagnetic steel plate

An electromagnetic steel plate and directional technology, applied in the direction of circuits, electrical components, magnetic cores/yokes, etc., can solve problems such as existing limits, and achieve the effect of suppressing iron loss and excellent actual iron loss characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0089] A slab comprising, by mass %, C: 0.05%, Si: 3.2%, Mn: 0.06%, Se: 0.02%, and Sb: 0.02%, with the balance consisting of Fe and unavoidable impurities, is produced by continuous casting, After heating to 1400° C., hot rolling was performed to form a hot-rolled sheet having a thickness of 2.6 mm, and then, the hot-rolled sheet was annealed at 1,000° C. Next, by cold-rolling twice via intermediate annealing at 1000° C., it was finished into a cold-rolled sheet having a final sheet thickness of 0.30 mm.

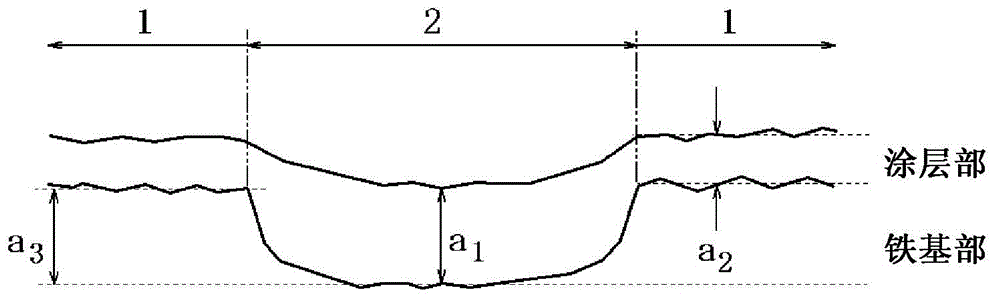

[0090]Then, a resist was applied by gravure offset printing, followed by electrolytic etching and resist stripping in an alkaline solution, thereby forming a film with a width of 150μm linear groove with a depth of 20μm.

[0091] Next, after decarburization annealing at 825°C, an annealing separator mainly composed of MgO was applied, and final annealing for secondary recrystallization and purification was performed at 1200°C for 10 hours.

[0092] Then, a tension coating ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com