Rotary electric machine system and vehicle

A technology for rotating electric machines and vehicles, which is applied to motor vehicles, vehicle components, hybrid vehicles, etc., and can solve problems such as difficulty in suppressing the cost of rotating electric machine units, ensuring the performance of rotating electric machine units and suppressing costs, etc., to achieve cost suppression and drag loss Reduced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

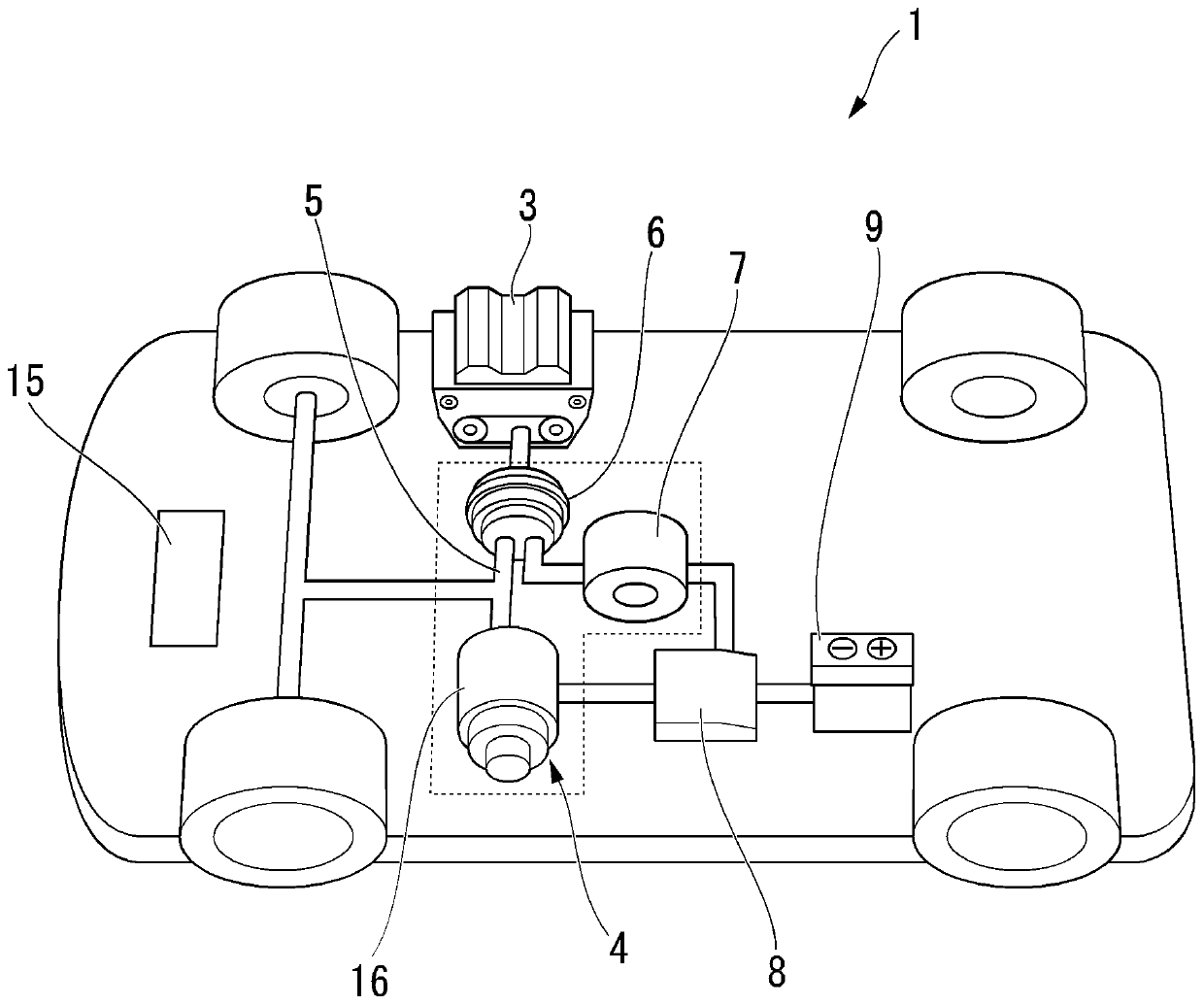

[0045] Such as figure 1 As shown, a hybrid vehicle 1 (vehicle) is provided with an internal combustion engine 3 and a rotary electric machine 16 , and travels with the driving force of at least one of the internal combustion engine 3 and the rotary electric machine 16 depending on the running state. That is, the hybrid vehicle 1 includes an internal combustion engine 3 , a rotary electric machine system 4 , a drive shaft (pedal shaft) 5 , a power distribution mechanism 6 , a generator 7 , an inverter 8 , and a battery 9 .

[0046] When the hybrid vehicle 1 is running, the internal combustion engine 3 , the rotary electric machine 16 , the generator 7 , the inverter 8 , and the like generate heat. Therefore, the hybrid vehicle 1 includes, for example, a refrigerant cooling mechanism 17 for cooling the rotary electric machine 16 and the generator 7 (see Figure 5 ).

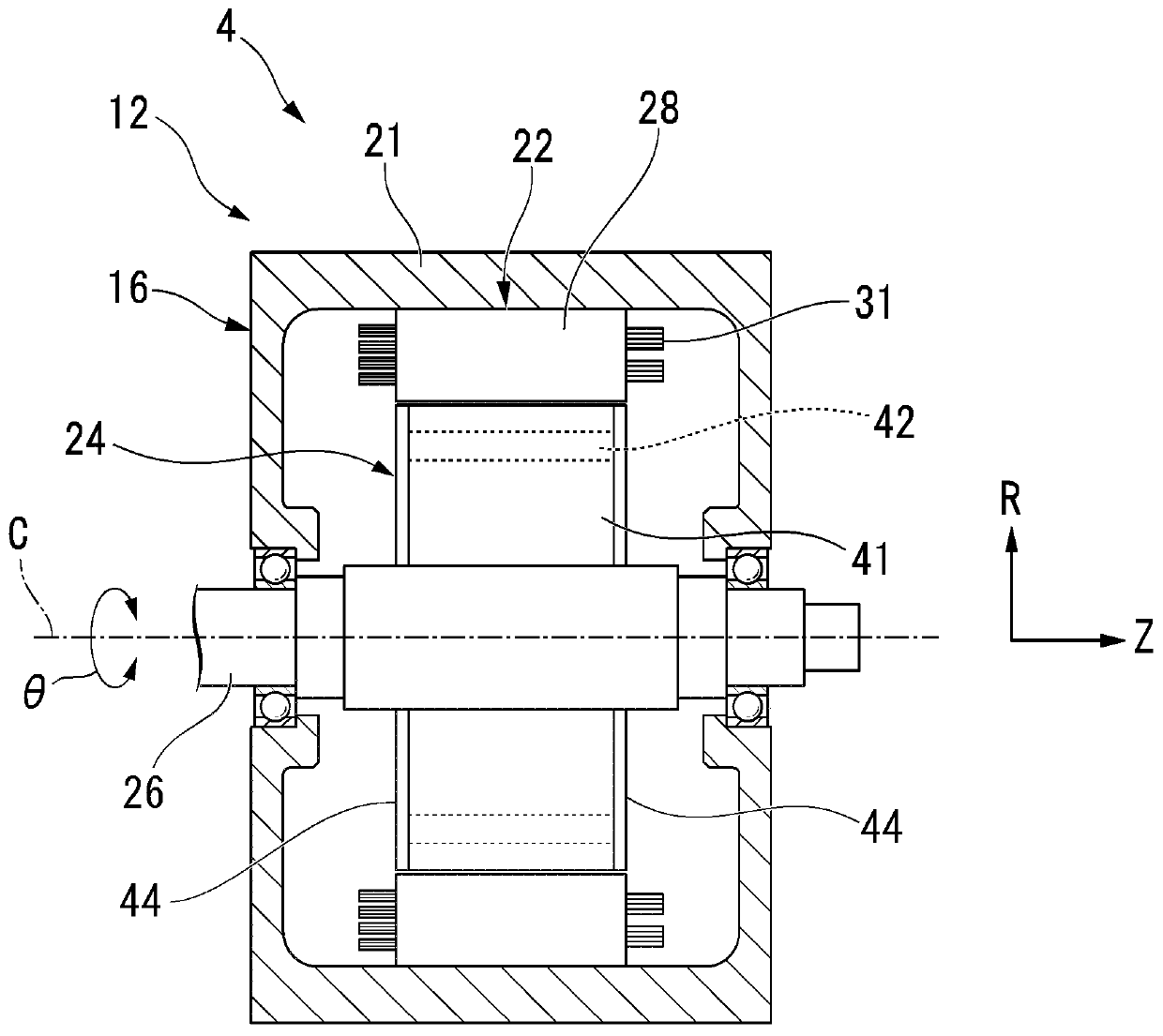

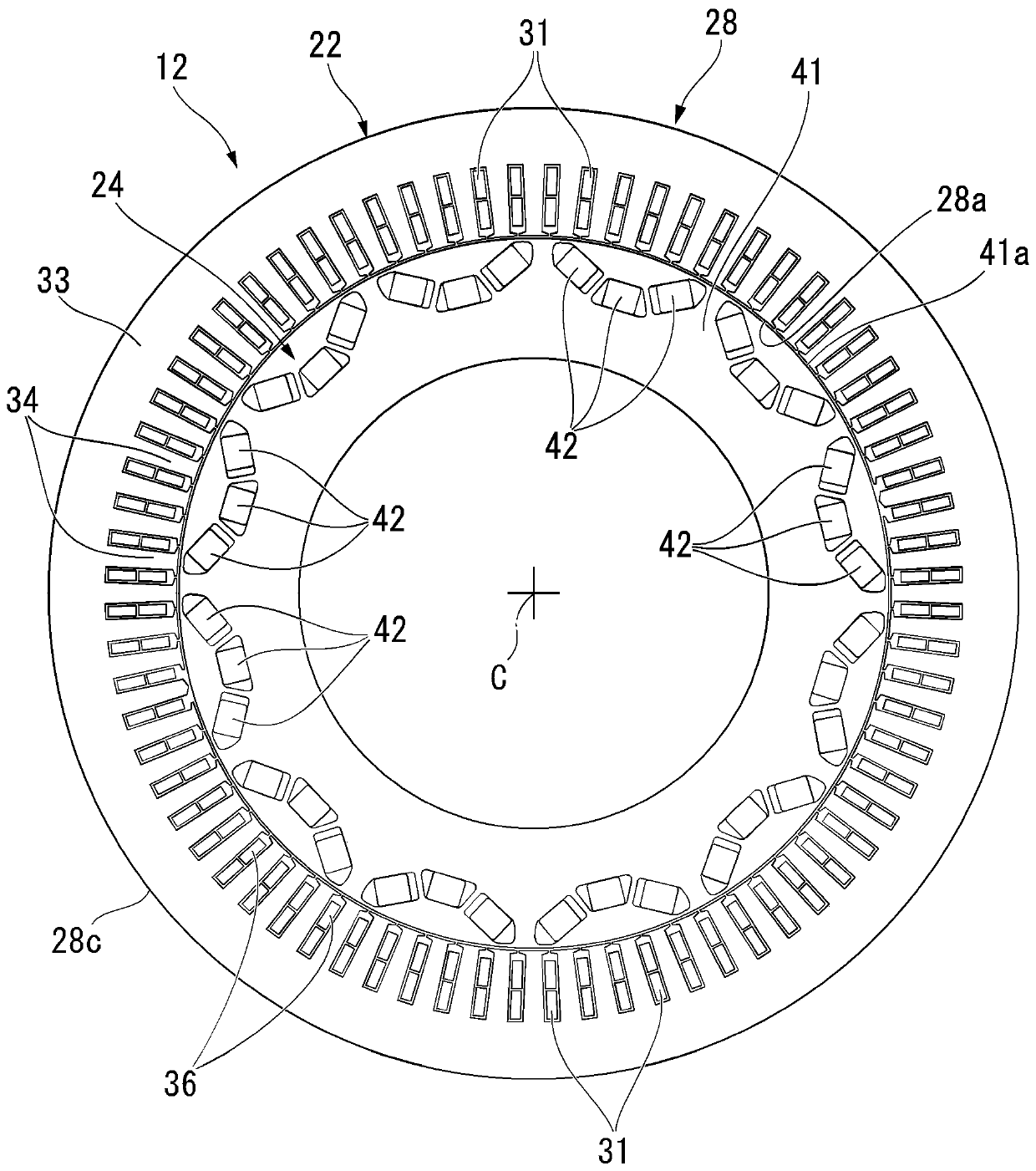

[0047] Such as figure 2 , image 3 As shown, the rotating electrical machine system 4 includes a rotating e...

no. 2 approach

[0124] Such as Figure 12 As shown, a hybrid vehicle 100 (vehicle) includes an internal combustion engine 101 , a rotating electric machine 102 , a drive shaft (pedal shaft) 103 , a transmission (planetary gear) 104 , and a generator 105 . The hybrid vehicle 100 runs with an engine instead of a motor in order to efficiently use energy during high-speed cruising, for example. In this state, when the rotating electric machine 102 is directly connected to the drive shaft 103 , the rotating electric machine 102 is rotated by the internal combustion engine 101 , and no-load loss (drag loss) occurs in the rotating electric machine 102 .

[0125]According to the hybrid vehicle 100 , by raising the temperature of the stator core of the rotary electric machine 102 , iron loss generated in the stator core can be suppressed. In this way, the drag loss of the rotary electric machine system can be reduced in the hybrid vehicle 100 by utilizing the phenomenon that the iron loss (eddy curre...

no. 3 approach

[0128] Such as Figure 13 As shown, a hybrid vehicle 110 (vehicle) includes an internal combustion engine 111 , a rotary electric machine 112 , a drive shaft (pedal shaft) 113 , an inverter 114 , a battery 115 , and a generator 116 . Hybrid vehicle 110 runs on an engine instead of a motor in order to efficiently use energy during high-speed cruising, for example. In this state, when rotating electric machine 112 is directly connected to drive shaft 113 , rotating electric machine 112 is driven to rotate by internal combustion engine 111 , and no-load loss (drag loss) occurs in rotating electric machine 112 .

[0129] According to the hybrid vehicle 110 , by increasing the temperature of the stator core of the rotary electric machine 112 , it is possible to suppress the iron loss generated in the stator core. In this way, the drag loss of the rotary electric machine system can be reduced in the hybrid vehicle 110 by utilizing the phenomenon that the iron loss (eddy current los...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com