Corn threshing machine

A threshing machine and corn technology, applied in threshing equipment, agricultural machinery and tools, applications, etc., can solve problems such as heterogeneity, blockage, and difficult production, and achieve simplified position adjustment mechanism, good technical and economic value, and increase market competition force effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be further described below in conjunction with the drawings and embodiments:

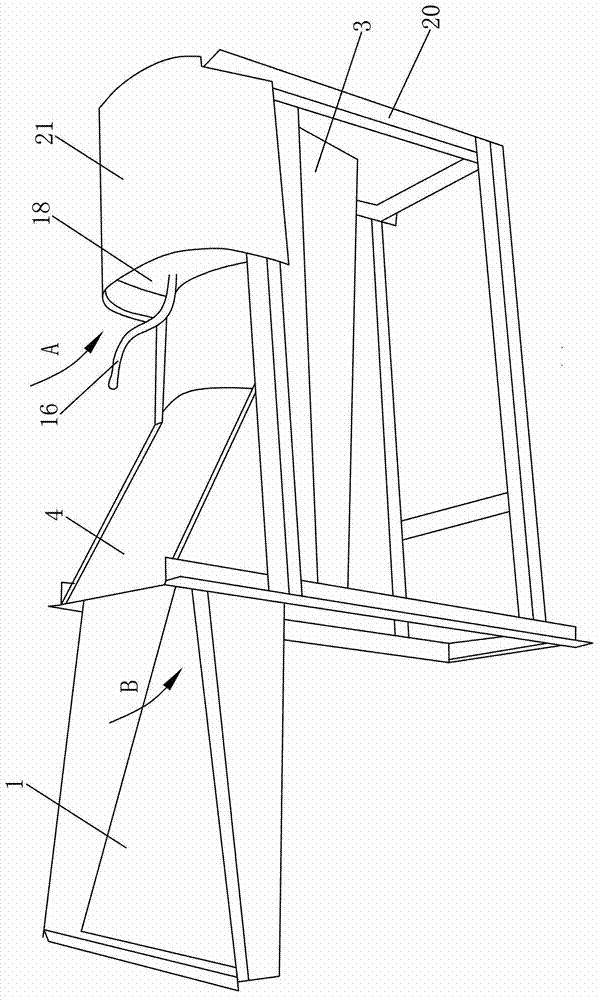

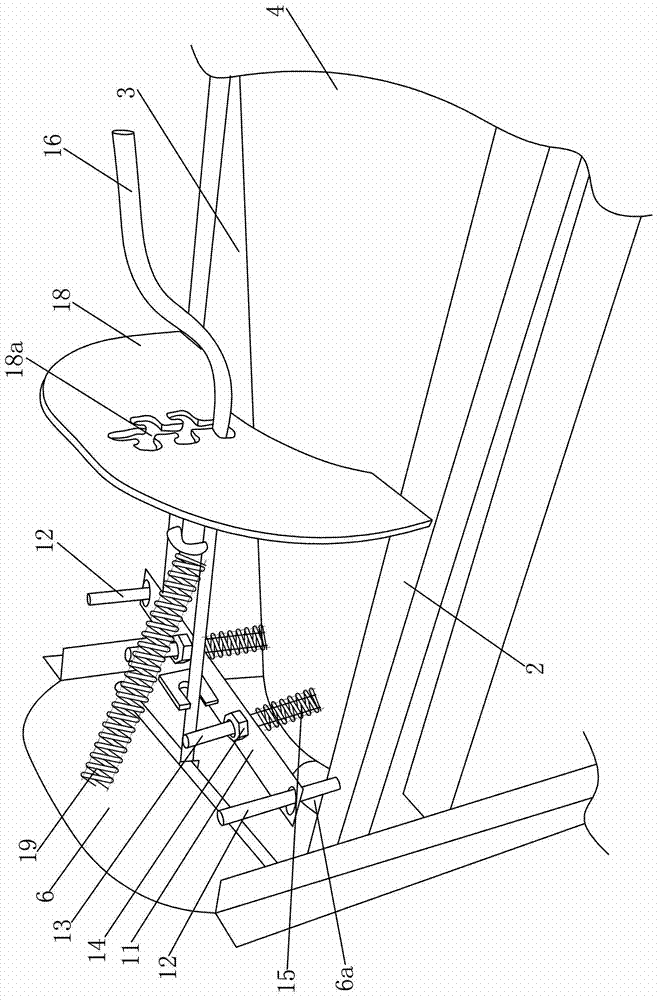

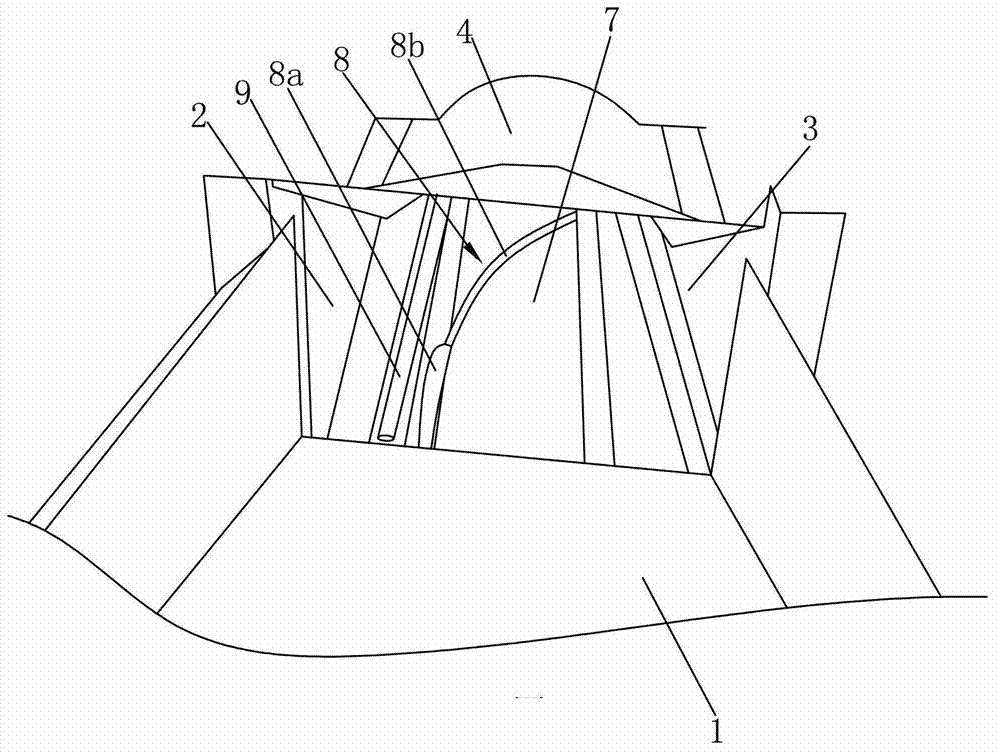

[0042] Such as Figure 1 to 4 As shown, a corn thresher is mainly composed of a feeding hopper 1, a left silo shell 2, a right silo shell 3, an upper silo shell 4, a grain output hopper 5, a discharge baffle 6, a threshing drum 7, and a spiral guide rib 8. The threshing gear lever 9, the discharging stopper 10 and the position adjustment mechanism. Wherein, the feeding hopper 1 is fixed at the feeding ends of the left silo shell 2 and the right silo shell 3, and the lower ends of the left silo shell 2 and the right silo shell 3 are fixedly connected with the lower silo shell (not shown in the figure) , And the left warehouse shell 2, the right warehouse shell 3 and the lower warehouse shell are fixedly supported on the frame 20.

[0043] The upper silo shell 4 is located between the left silo shell 2 and the right silo shell 3. The left side of the feed end of the uppe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com