Crane as well as fixed point hoisting control method, equipment and system thereof

A control method and crane technology, applied in the direction of transportation and packaging, load hanging components, etc., can solve the problems of increasing the workload of command personnel, harsh environment, and difficult operation, so as to improve environmental adaptability and humanization, and reduce command intensity , the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Hereinafter, the present invention will be described in detail with reference to the drawings and examples. It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other.

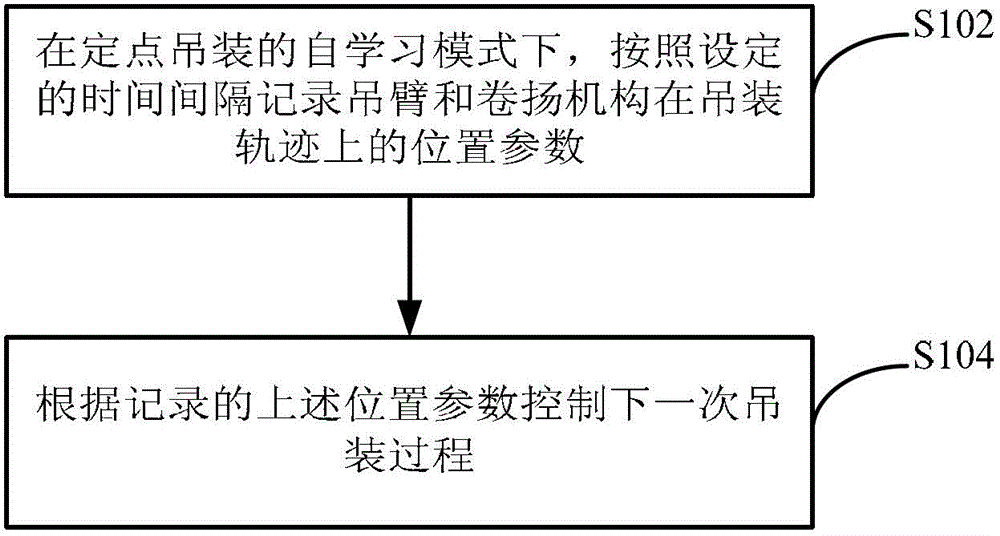

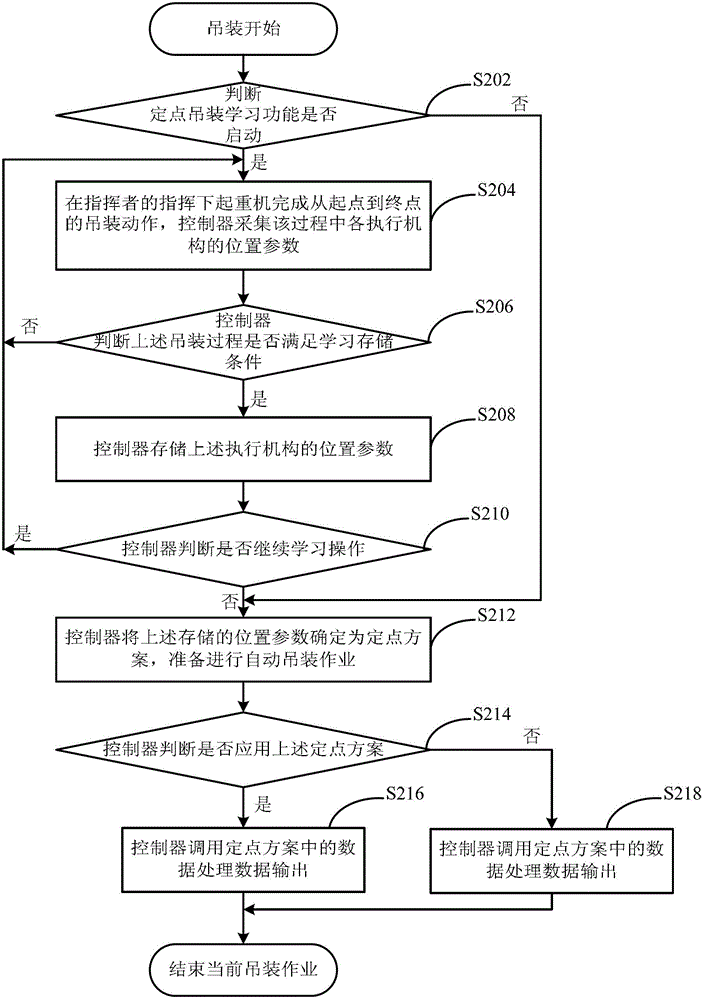

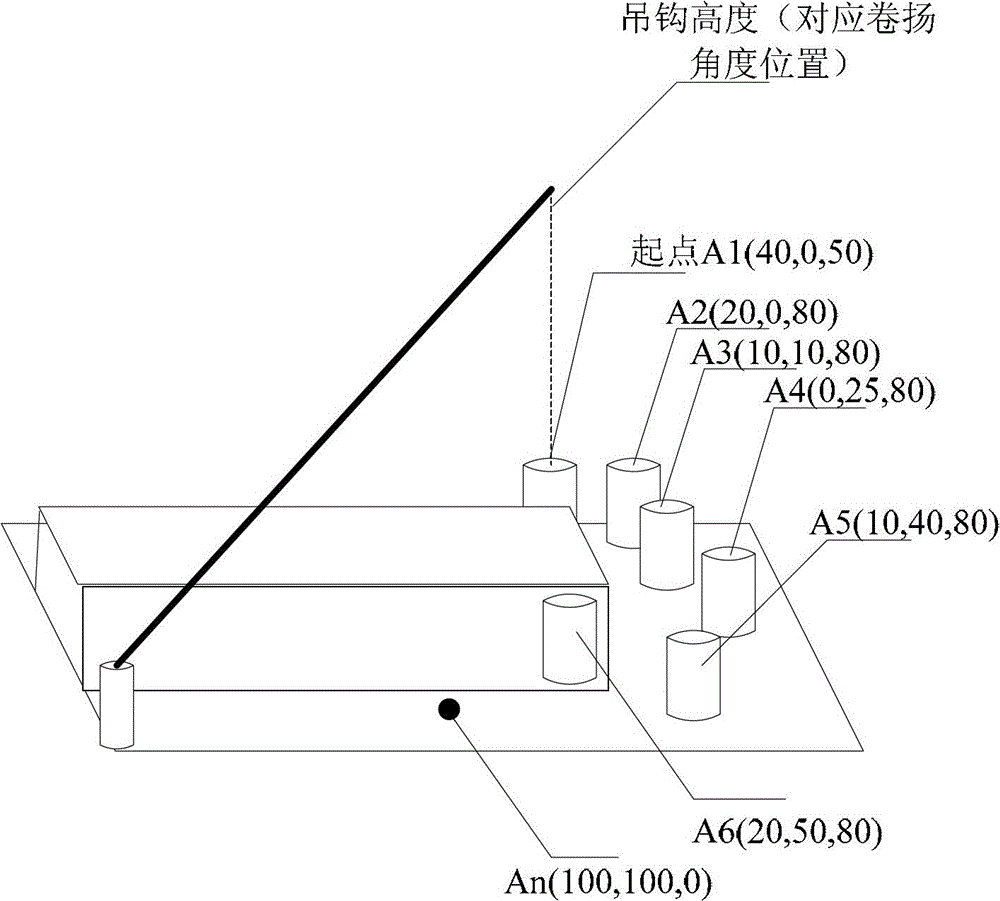

[0027] The fixed-point hoisting in the embodiment of the present invention refers to a process in which the starting point and the end point of the hoisting are fixed, and the middle route is limited or not during the hoisting operation of the crane. Considering that the fixed-point hoisting process in the related art usually relies on the commander to direct the operation every time, the operation is cumbersome and the work efficiency is low, the embodiment of the present invention provides a self-learning mechanism. In the embodiment of the present invention, the self-learning mechanism It means that the control system has an automatic "learning" memory function. When the operation is set to "learn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com