A method for separating and purifying epothilone by high-speed countercurrent chromatography

A high-speed counter-current chromatography, epothilone technology, applied in the field of high-speed counter-current chromatography separation and purification of epothilone, can solve problems such as no high-speed counter-current chromatography epothilone, to avoid sample loss, high purity, separation and purification The effect of mild process conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

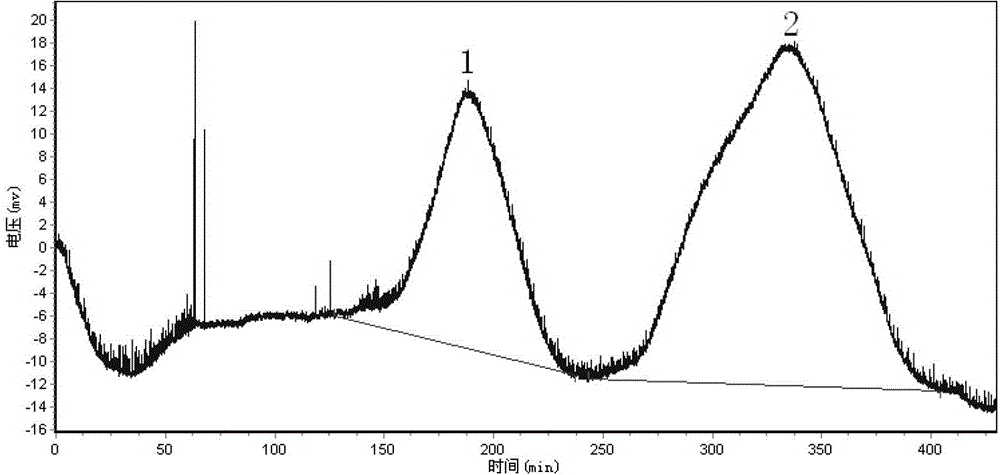

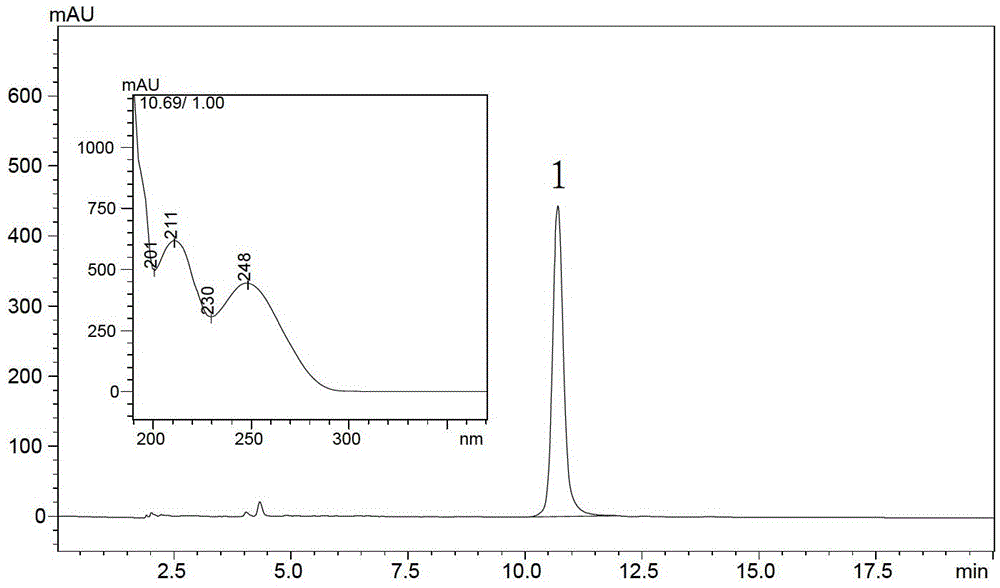

[0049] Prepare a solvent system, wherein the volume ratio of n-hexane:ethyl acetate:methanol:water is 1:1:1:1, a total of 1500ml is miscible in a separatory funnel, shake it up and let it stand for stratification, and take the upper phase as the stationary phase , the lower phase is the mobile phase, after ultrasonic degassing, first pump the stationary phase into the separation column, set the temperature of the constant temperature circulator to 20°C, then turn on the host of the high-speed countercurrent chromatograph, adjust the speed of the host to 850rpm, and the mobile phase to 1.5ml / min flow rate pumped into the separation column, until the entire stationary phase - mobile phase system to establish a dynamic equilibrium, balance 10min.

[0050] The retention rate ρ of this solvent system is 78.8% (ρ=(V 总 -V 出 ) / V 总 ×100%, where V 总 : Total volume of the separation column pipeline (ml), V 出 : volume of stationary phase pushed out by mobile phase during equilibration ...

Embodiment 2

[0053] Prepare a solvent system, wherein the volume ratio of n-hexane:ethyl acetate:methanol:water is 1.2:1.2:1:1, a total of 1500ml is miscible in a separatory funnel, shake it up and let it stand for stratification, and take the upper phase as the stationary phase , the lower phase is the mobile phase. After ultrasonic degassing, first pump the stationary phase into the entire separation column, set the temperature of the constant temperature circulator to 20°C, and then turn on the main engine of the high-speed countercurrent chromatograph, adjust the main engine speed to 850rpm, and the mobile phase to Pump at a flow rate of 1.5ml / min into the separation cartridge until the entire stationary phase-mobile phase system establishes a dynamic equilibrium for 10 minutes.

[0054] The retention rate p of this solvent system when calculating equilibrium is 80.5% (p=(V 总 -V 出 ) / V 总 ×100%, where V 总 : Total volume of the separation column pipeline (ml), V 出 : volume of stationa...

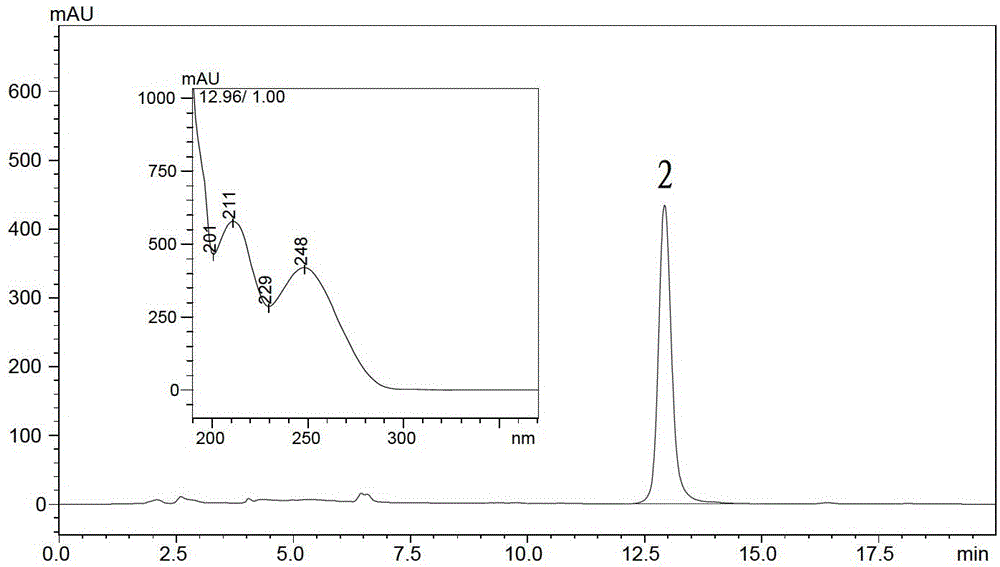

Embodiment 3

[0057] Prepare a solvent system, wherein the volume ratio of n-hexane: ethyl acetate: methanol: water is 1:0.8:0.8:1, a total of 1500ml is miscible in a separatory funnel, shake it up and let it stand for stratification, and take the upper phase as the stationary phase , the lower phase is the mobile phase. After ultrasonic degassing, first pump the stationary phase into the entire separation column, set the temperature of the constant temperature circulator to 20°C, and then turn on the main engine of the high-speed countercurrent chromatograph, adjust the main engine speed to 850rpm, and the mobile phase to Pump at a flow rate of 1.5ml / min into the separation cartridge until the entire stationary phase-mobile phase system establishes a dynamic equilibrium for 10 minutes.

[0058] The retention rate p of this solvent system when calculating balance is 82.5% (p=(V 总 -V 出 ) / V 总 ×100%, where V 总 : total volume of the column tubing (ml), V 出 : volume of stationary phase pushe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com