Bridge rotation constructing process and rotation system

A construction technology and swivel technology, which is applied in the field of bridge swivel construction technology and swivel system, can solve the problem of non-reusable swivel hinges, achieve great application and promotion value, good versatility, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in combination with specific embodiments and accompanying drawings.

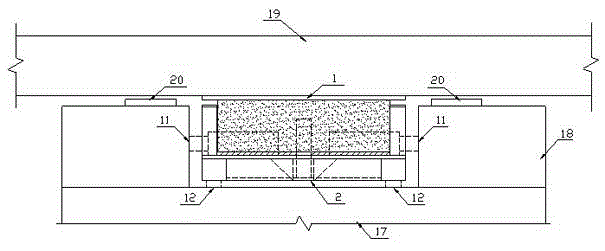

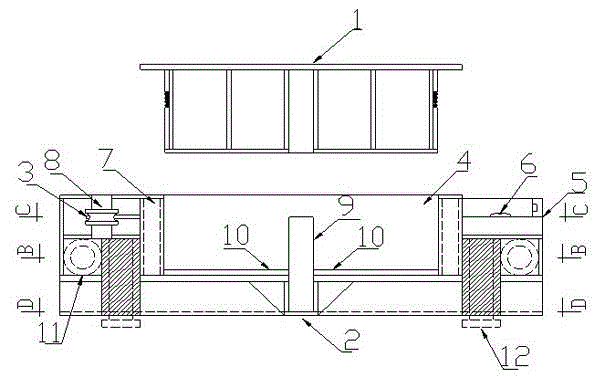

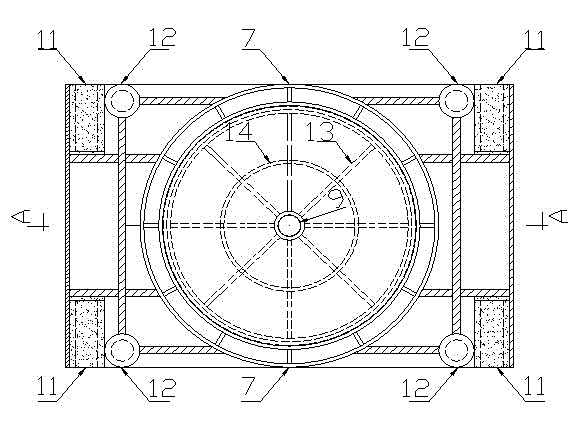

[0031] Such as Figure 1 to Figure 5 As shown, a bridge swivel construction process includes the following steps:

[0032] (1) After the pouring of the main pier of the bridge and the cover beam 17 is completed and reaches the design strength, the sliding track is set on the top of the cover beam 17, and the positioning pads 18 are poured on both sides of the sliding track, and the support 20 is installed on the top of the positioning pad 18, and the swivel system Installed on the sliding track, between the positioning pads 18, the swivel system includes an upper turntable 1, a lower turntable 2, a vertical hydraulic jack set 12, a horizontal hydraulic jack set 11, a fixed steering pulley 8, a traction steel beam 3 and Continuous tension jack 5, the lower turntable 2 is provided with a concave installation groove 4, the center of the installation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com