Safety device for tail end hose of pump truck

The technology of a terminal hose and a safety device is applied in the field of the fixing mechanism for the terminal hose of a pump truck, which can solve problems such as easy swing back, and achieve the effects of low production cost, improved operation safety performance, and obvious restriction effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

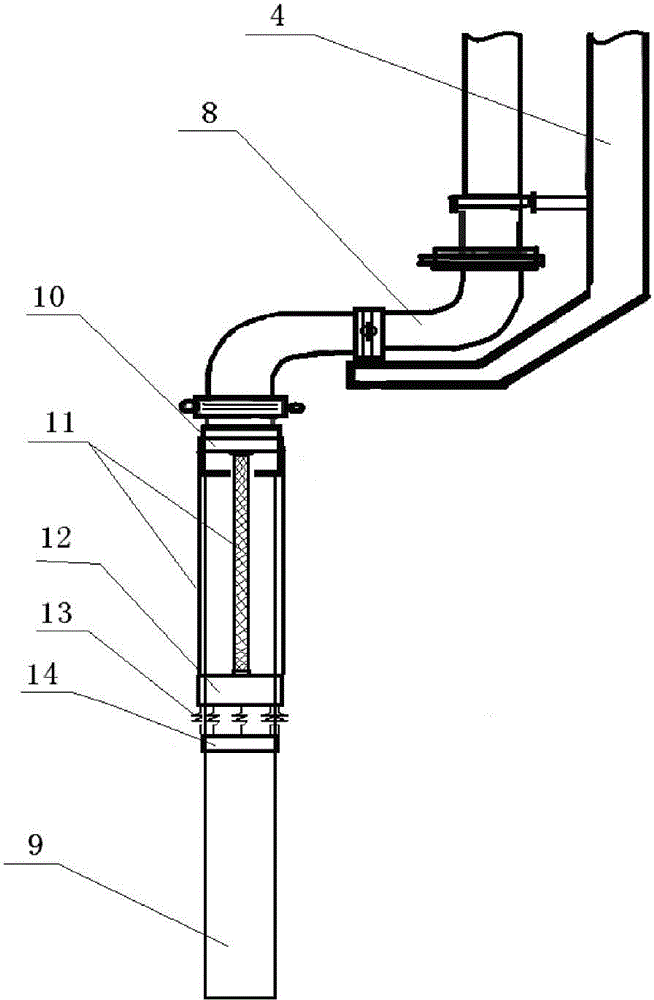

[0026] Such as image 3 As shown, the end hose safety device of the pump truck of the present invention includes a fixed ring 10 fixed on the upper part of the end hose 9 and a reset ring 14 fixed on the middle of the end hose 9, and the tension ring 12 can be moved up and down on the end hose. 9 and located between the fixed ring 10 and the reset ring 14, it is connected to the fixed ring 10 through 4 tension safety ropes 11 arranged on the side of the end hose 9, and the tension ring 12 and the end hose 9 maintain a certain degree of looseness , can slide up and down; the lower part of the tension ring 12 is connected with the reset ring 14 through 8 return springs 13, wherein, the distance between the tension ring 12 and the reset ring 14 is based on the preload distance of the return spring 13. In this embodiment, the reset The length of the spring 13 is 1 cm, the total length of the end hose is 3 meters, and the height of the tension ring is 10 cm, so as to ensure that th...

Embodiment 2

[0028] The difference from Example 1 is that the total length of the end hose is 3 meters, the height of the tension ring 12 is 11 cm, and the length of the return spring 13 is 2 cm. All the other operating modes are the same as in Example 1.

Embodiment 3

[0030] The difference from Example 1 is that the total length of the end hose is 3 meters, the height of the tension ring 12 is 12 cm, and the length of the return spring 13 is 3 cm. All the other operating modes are the same as in Example 1.

[0031] The present invention is obtained through long-term production practice and creative labor by technical research and development personnel, and it has been tried out in the company. Due to the low production cost and good application effect of the present invention, it is well received by front-line workers.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com